Technology for processing steaming chamber of steam turbine

A processing technology and a technology for a steam chamber, which is applied to the processing technology field of the steam chamber of a steam turbine, can solve the problems of troublesome processing, irregular shape of the steam chamber, difficult combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

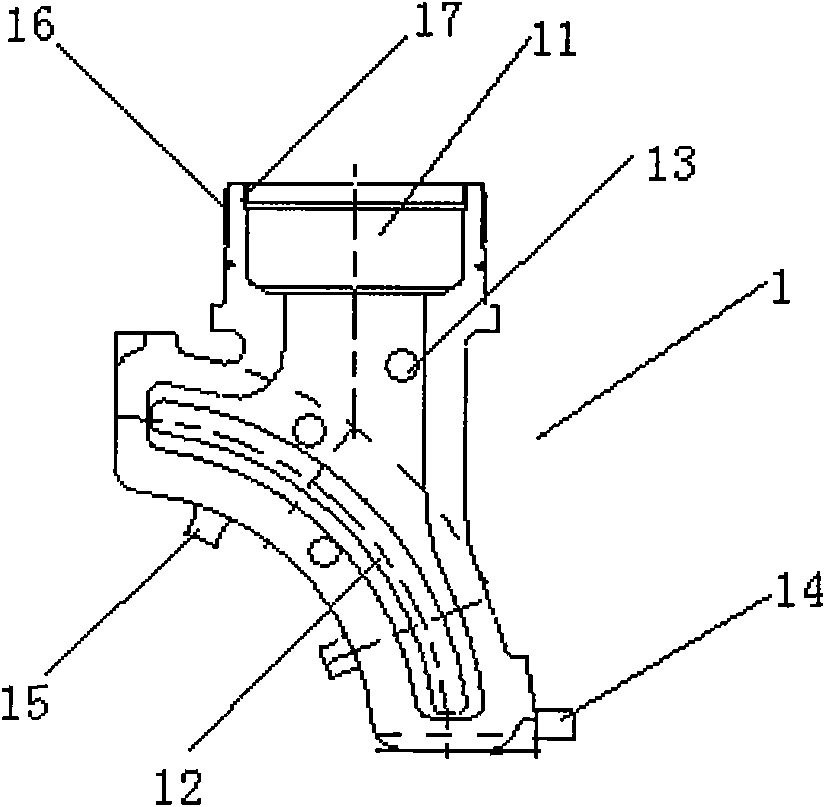

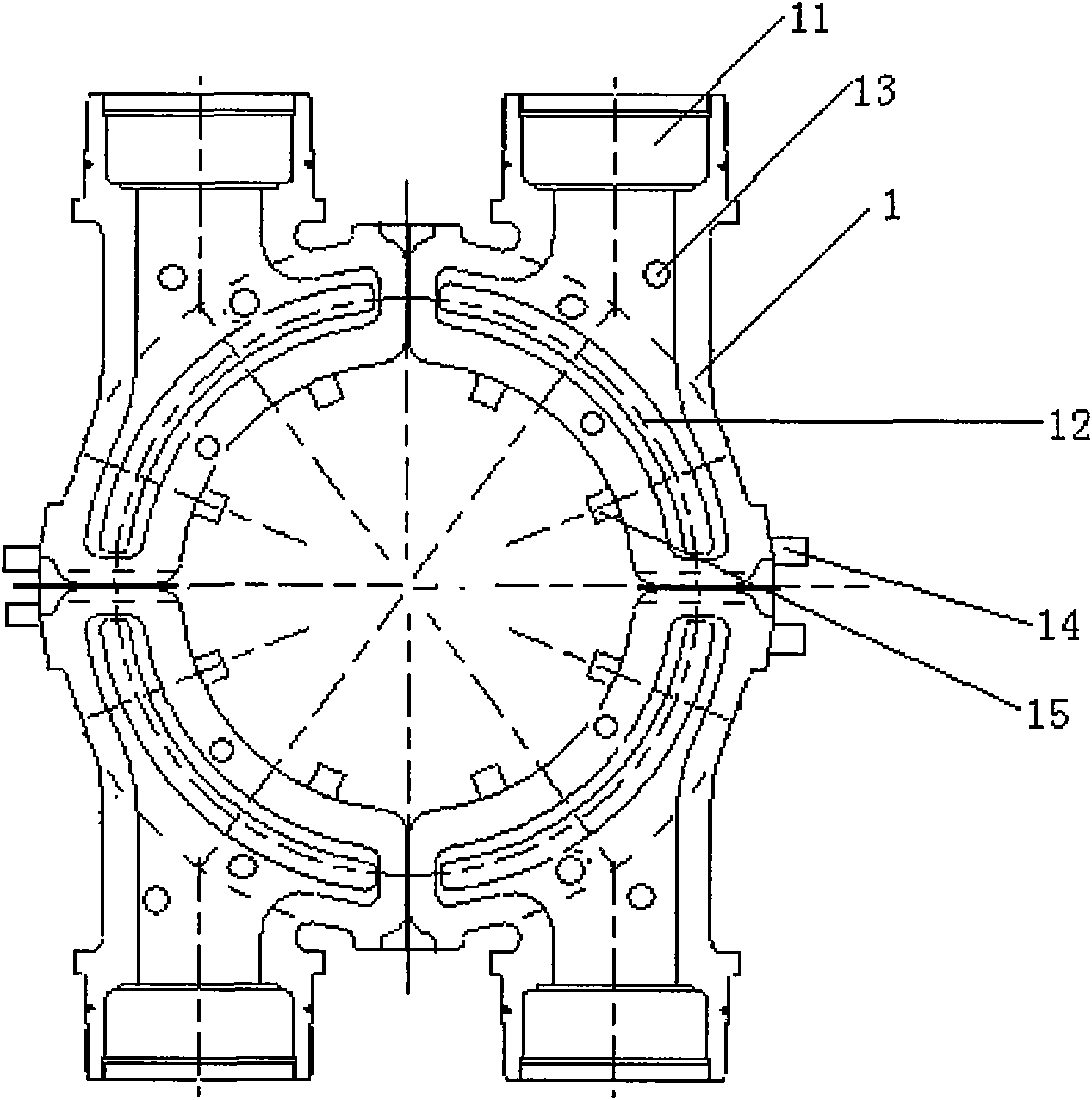

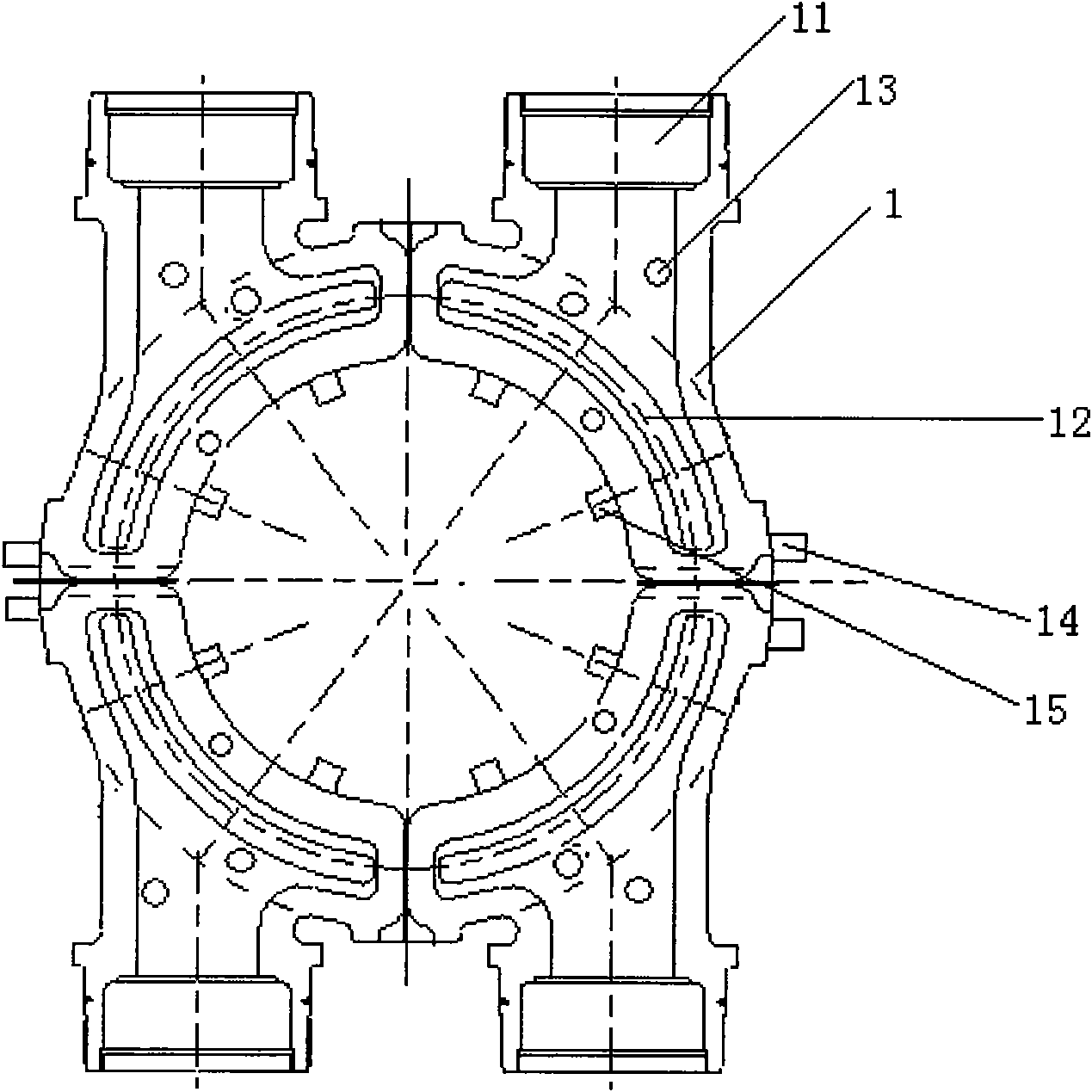

[0021] like figure 1 As shown, the steam chamber 1 includes a steam inlet 11 and a fan-shaped steam outlet 12. When the steam chamber 1 is casting, three supporters 13 for leveling the plane are arranged on the front of the steam chamber 1. In the steam chamber 1 A stand 14 for aligning the vertical plane is arranged on the outer surface, and two rests 15 for centering are arranged on the inner arc surface of the steam chamber 1 . After the casting of the steam chamber 1 is completed, the steam inlet 11 and the fan-shaped steam outlet 12 of the steam chamber 1 are roughly machined, and then water is injected into the chamber of the steam chamber 1 and the steam inlet 11 and the steam chamber are sealed by welding with a stuffy plate. The steam outlet 12 is used to perform a hydrostatic test on the steam chamber to check whether there is wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com