Press

A technology of presses and bars, applied in the field of presses, can solve the problems of complex structure, large action space, increase in quantity, etc., and achieve the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

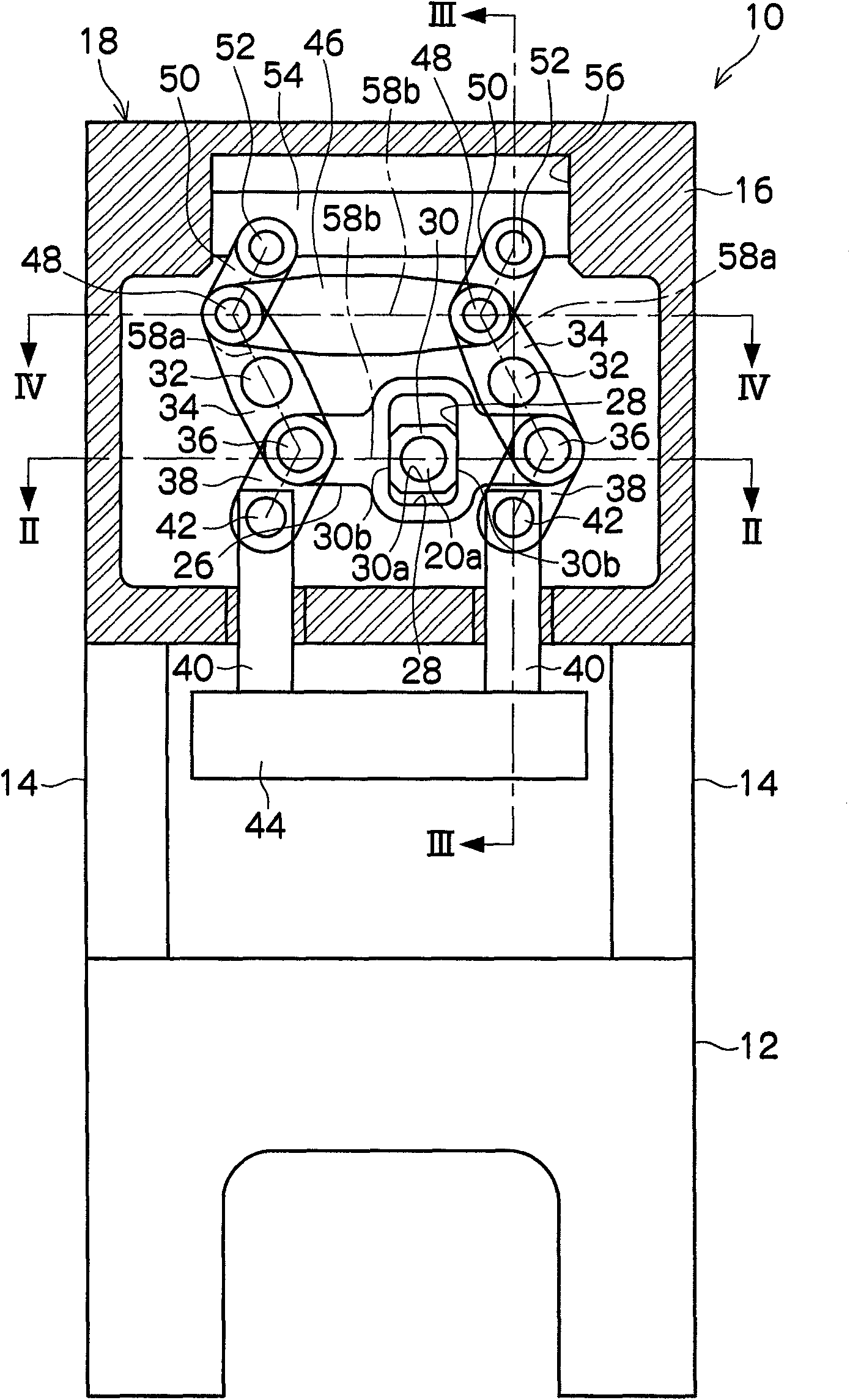

[0025] Such as figure 1 As shown, the press 10 of the present invention includes a machine base 12 and a frame 18, wherein the frame 18 has a plurality of struts 14 upstanding from the machine base to hold on the machine base in a spaced manner from the machine base 12. The upper beam (crown) 16 . The beam 16 is formed in a rectangular box shape as a whole, and a lower mold part is provided on the base 12 located below the beam 16, although not shown in the figure.

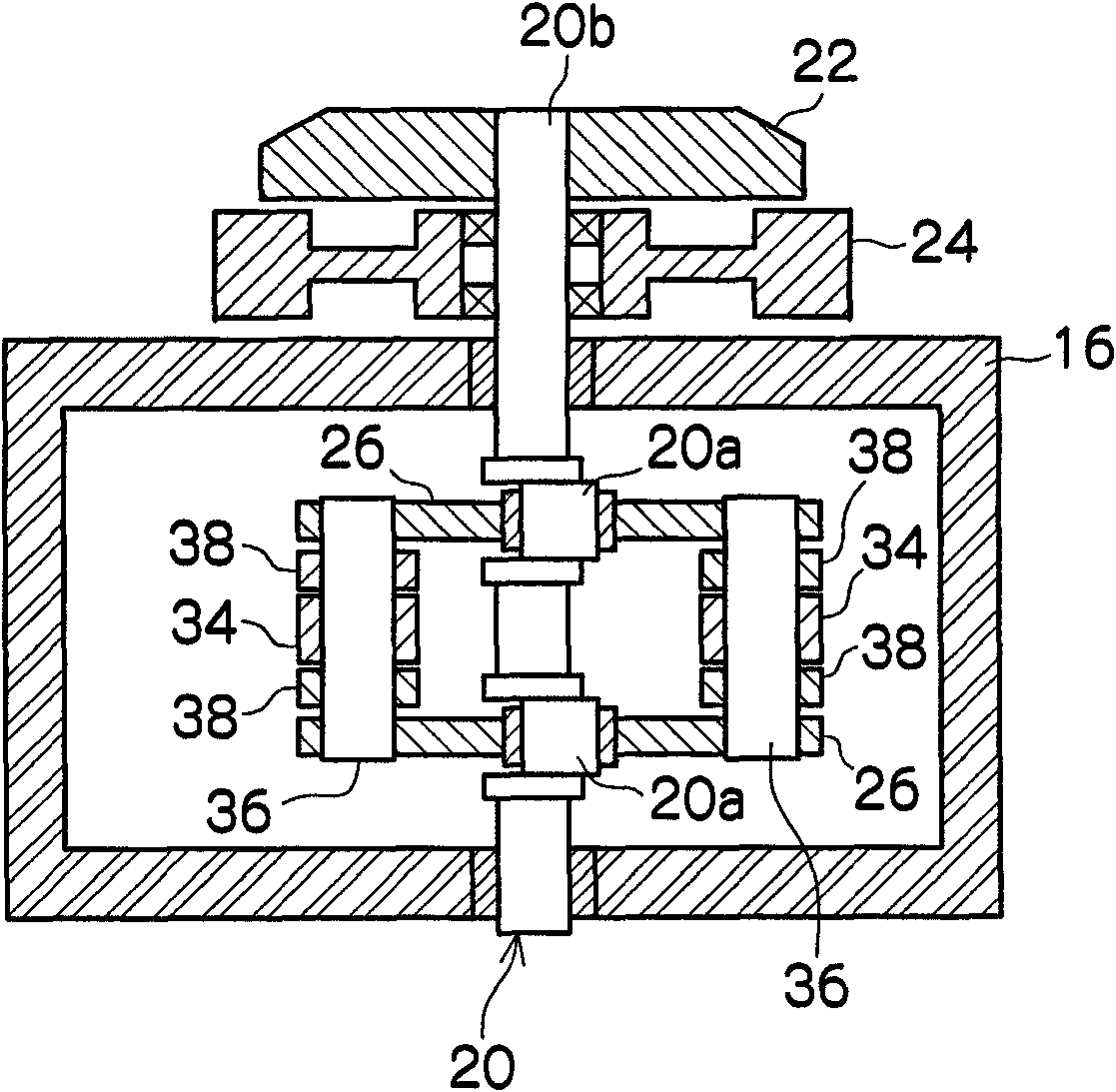

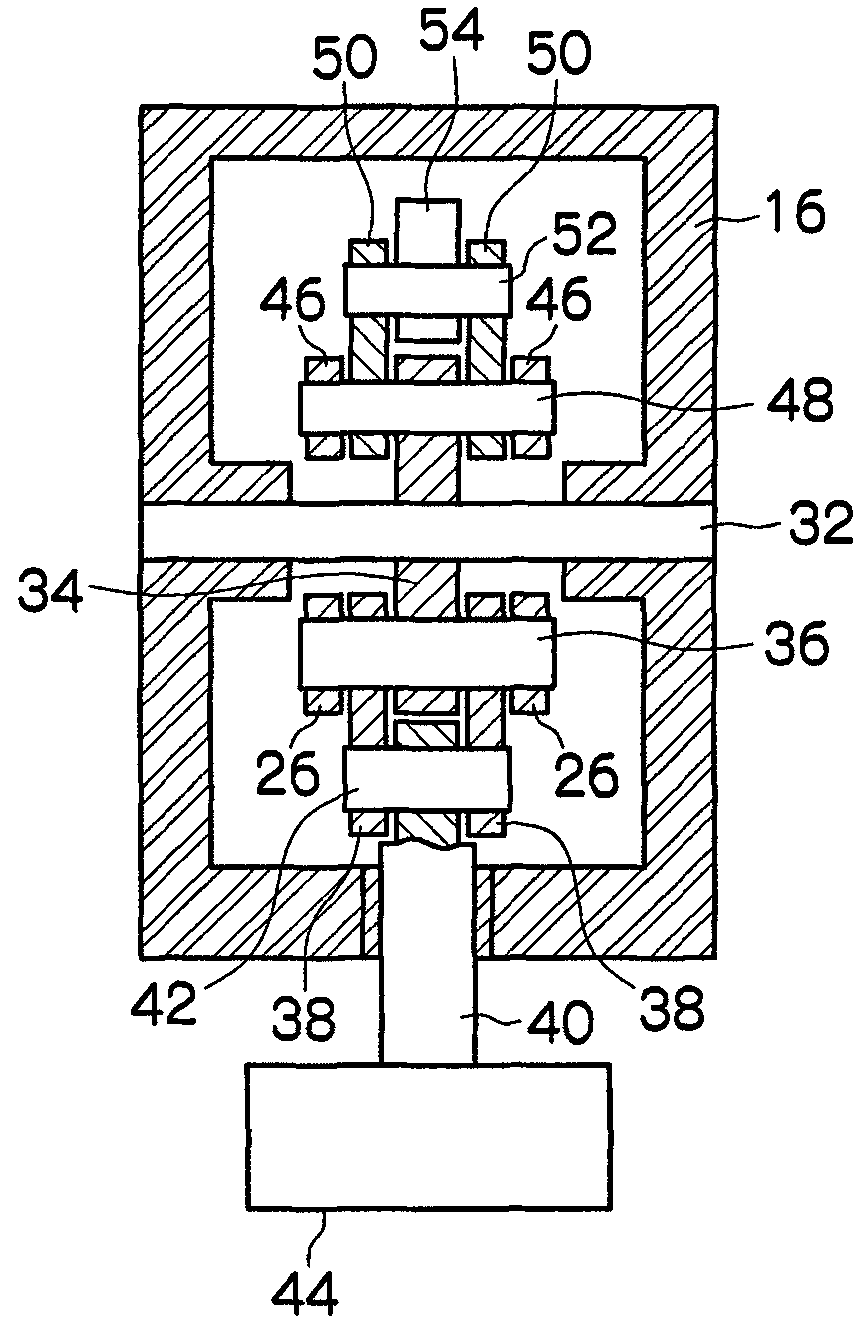

[0026] Such as figure 2 As shown, in the beam 16 , a crankshaft 20 having a pair of eccentric portions 20 a has one end of a main shaft portion 20 b protruding greatly from the beam 16 , and the crankshaft 20 is rotatably held. The protruding end of the main shaft part 20b is provided with: a driving force transmission device 22 having a conventionally known clutch and brake capable of intermittently transmitting the rotational force surrounding the main shaft part 20b of the crankshaft 20; and a flywheel 24. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com