Automatic unstacking machine of wheels

A stacker and automatic technology, which is applied in the field of automatic wheel unstacking machines, can solve the problems of no wheels, low unstacking efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

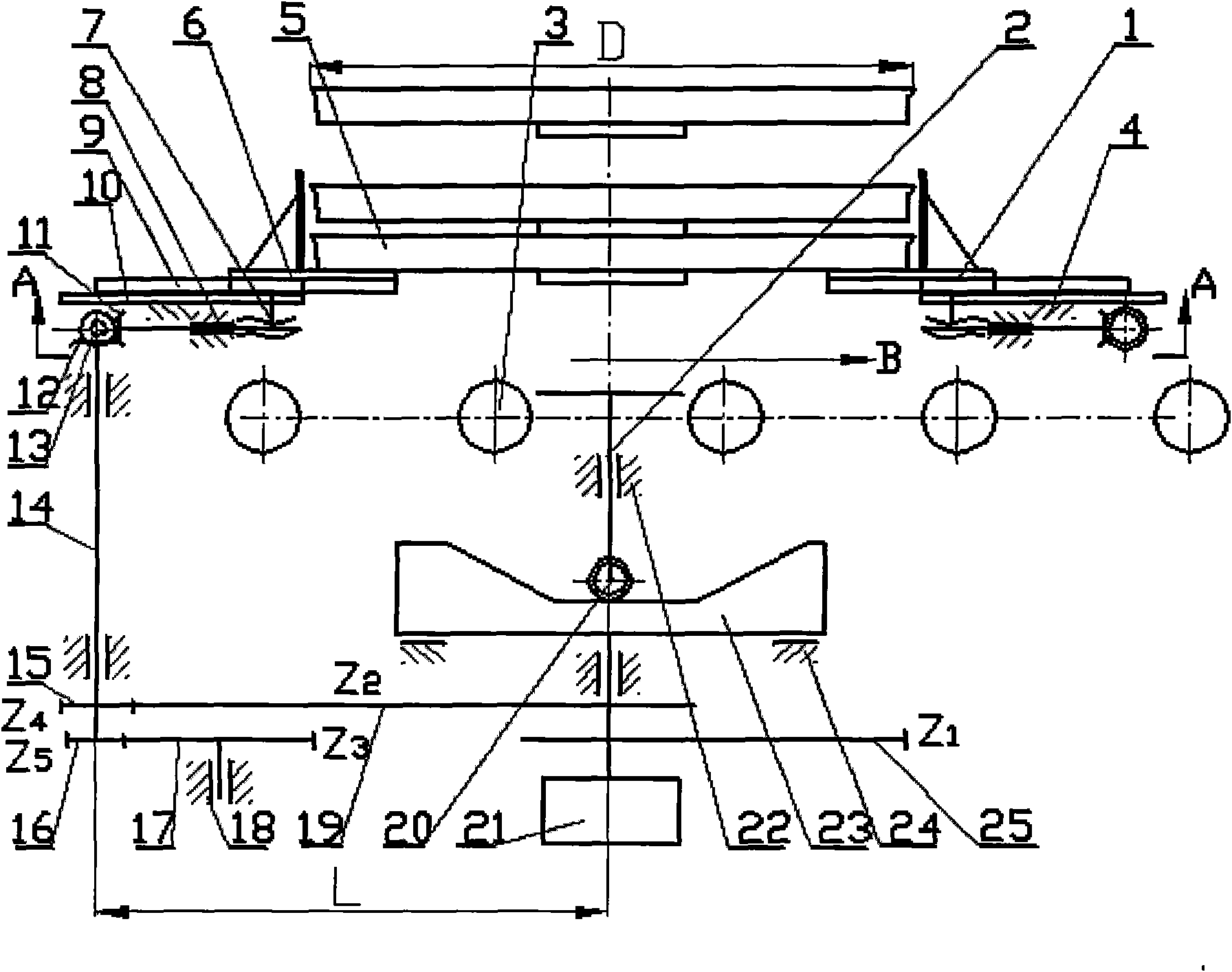

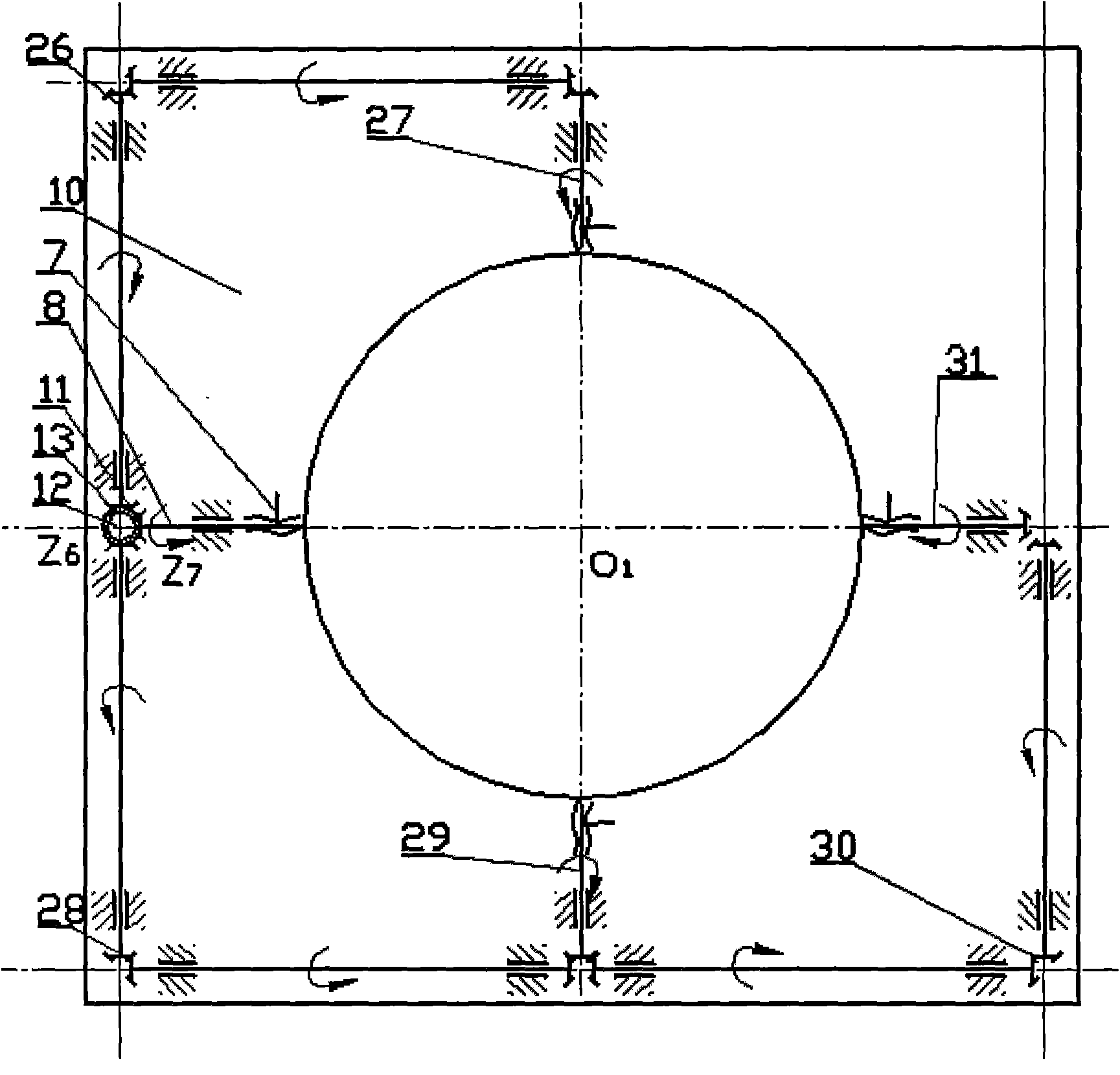

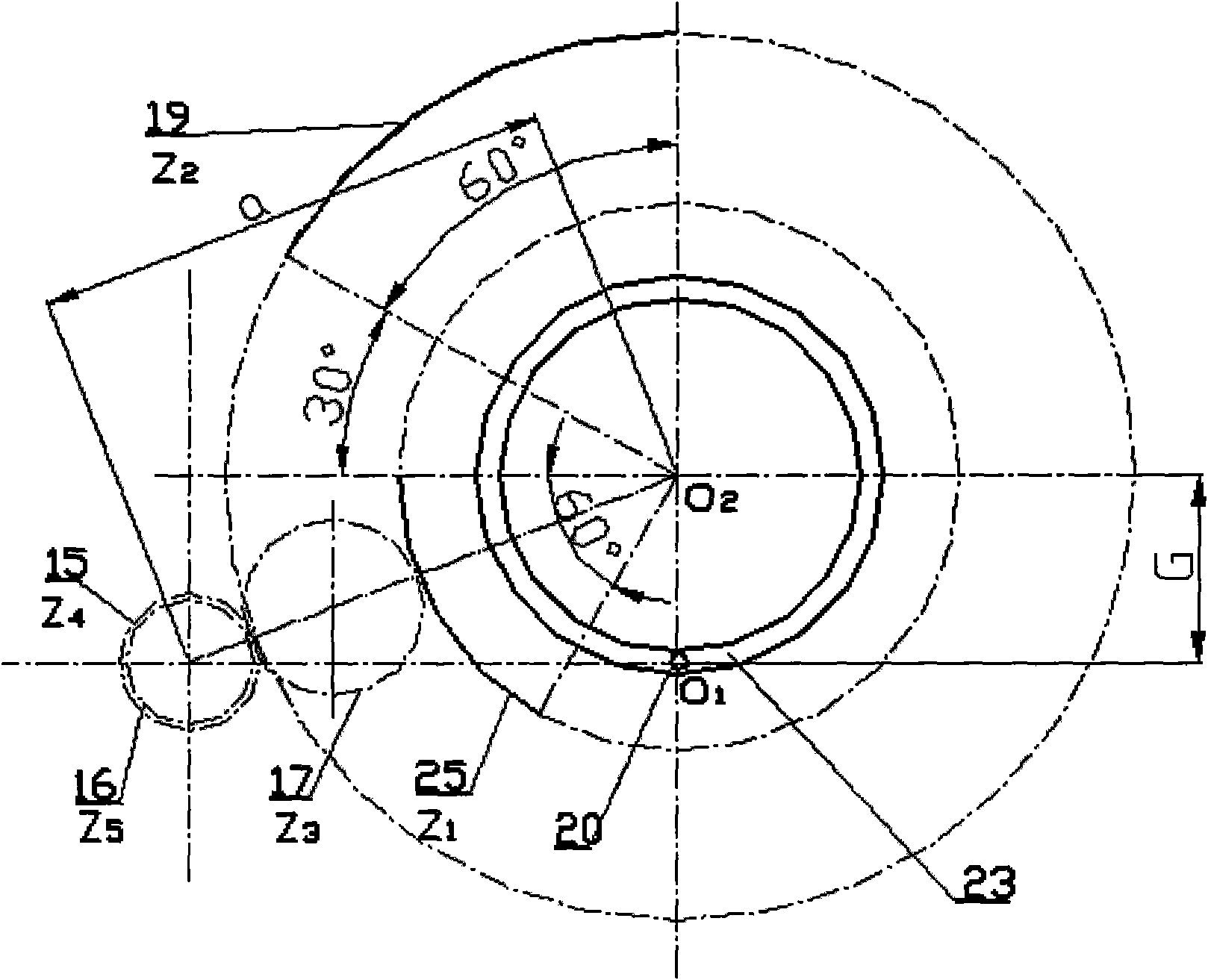

[0029] An automatic unstacking machine for a wheel stack (5) with an outer diameter of φ1000mm and a wheel number of 8. Frame (4) consists of four parts (attached figure 1 , 2 , 3 shown). The supporting claw advancing and retreating device (1) and the cam ejector rod lifting device (2) are driven by a three-in-one reduction motor (21), and are linked with the action of the conveying roller table (3). The support claw advance and retreat device (1) is installed on the workbench (10), the wheel stack (5) is hoisted by the crane onto the four evenly distributed support claws (6), and the workbench (10) is placed on the conveying roller table (3) Above, the cam ejector rod elevating device (2) is installed below the conveyor roller table (3), and the cam ejector rod (20) is positioned in the middle of the two rollers directly below the unstacking machine of the conveyor roller table (3). The main technical parameters of the wheel automatic destacking machine are: wheel diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com