Method for preparing environment-friendly black low-temperature curing cathode electrophoresis coating

A cathodic electrophoretic coating, an environmentally friendly technology, used in electrophoretic coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as the inability to meet the development of coating coatings, and achieve the effect of good curing degree and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

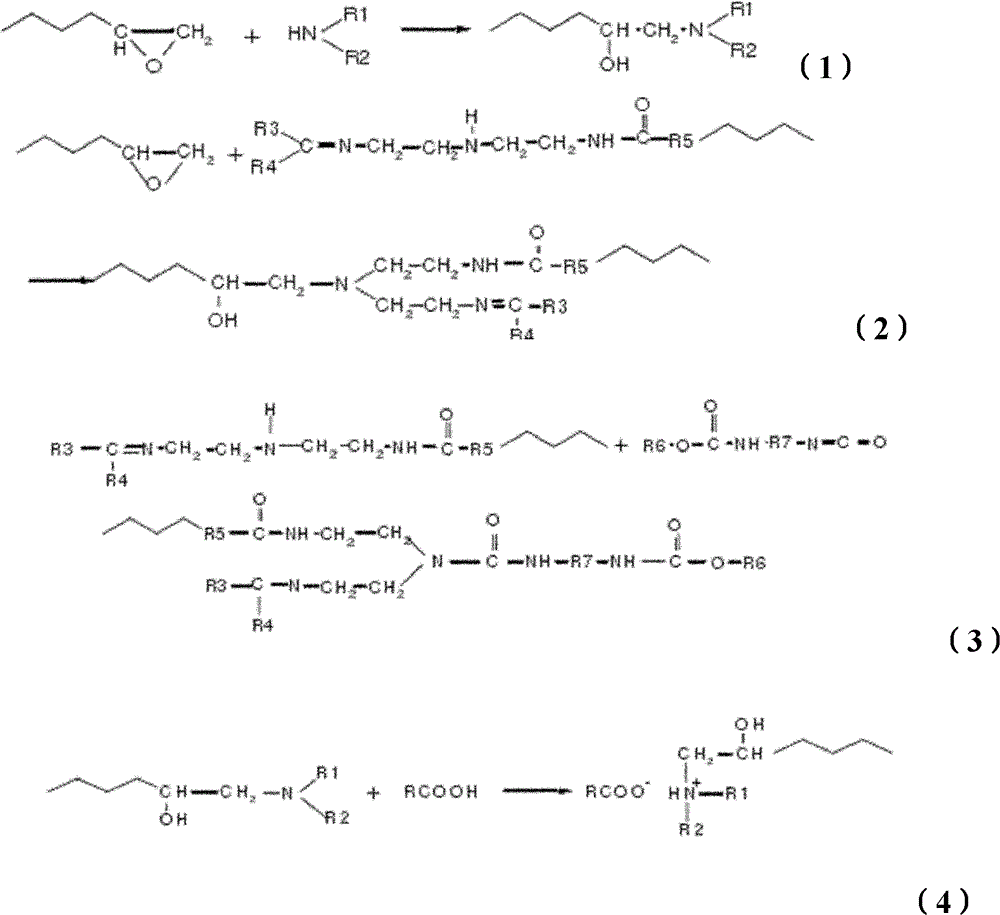

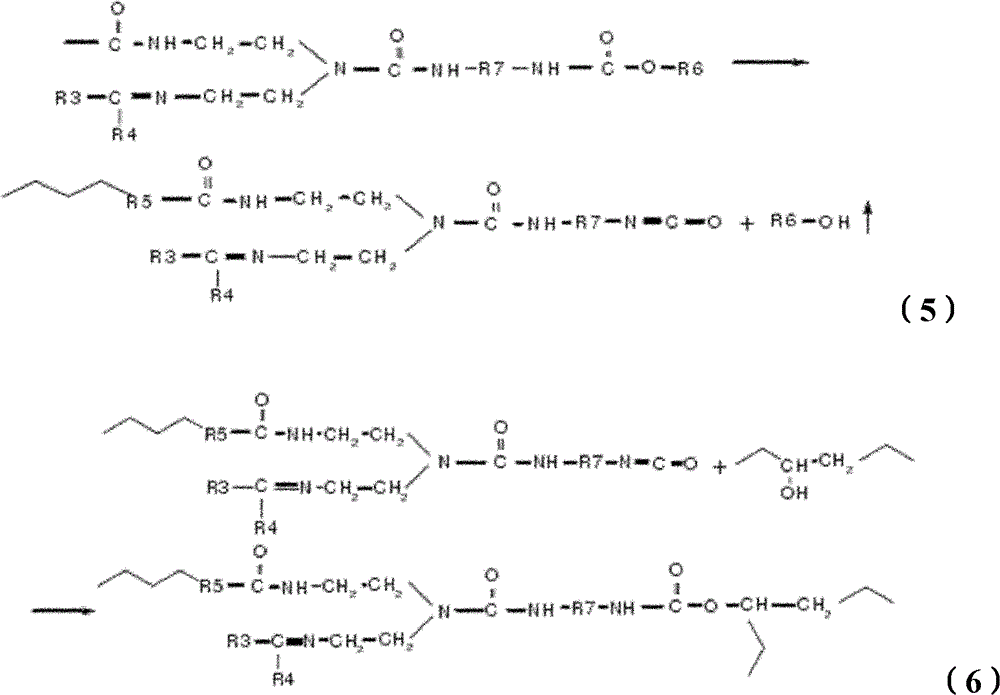

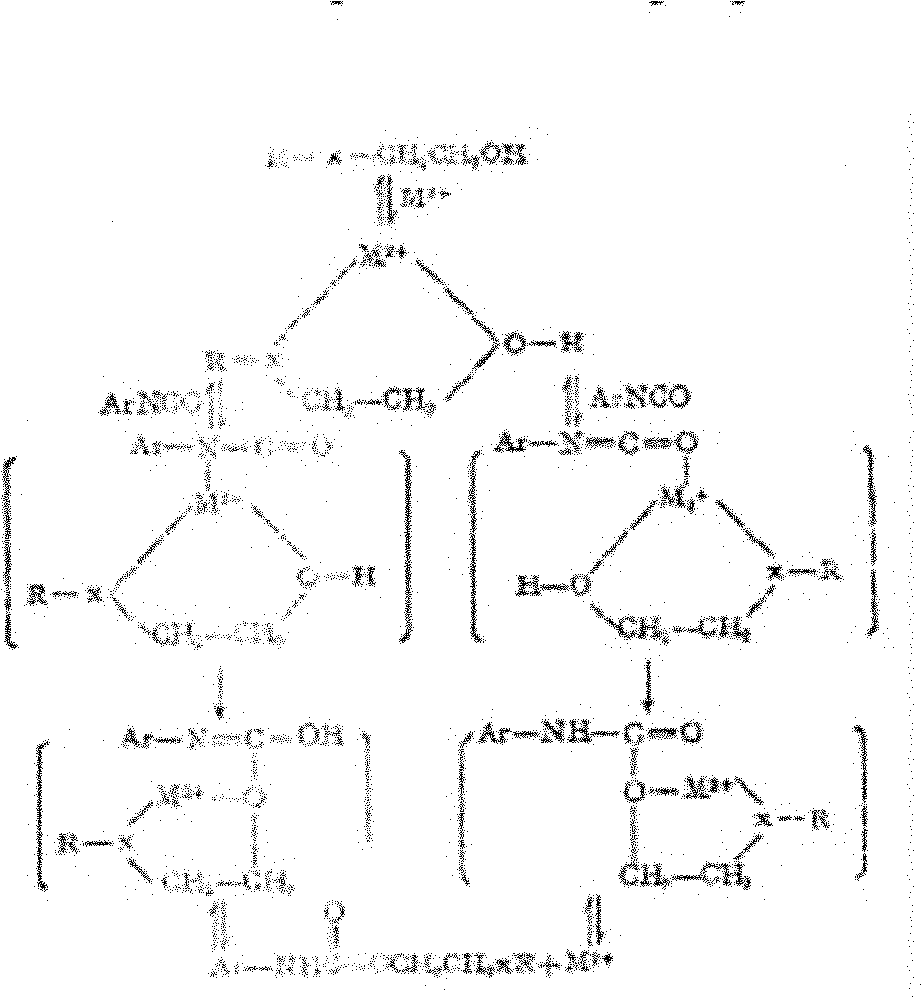

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples.

[0044] 1. Preparation of emulsion

[0045] Preparation of curing agent system

[0046] Put 100g of toluene diisocyanate and 5g of methyl isobutyl ketone into a four-necked flask with a condenser, nitrogen protection and reflux device, and raise the temperature to 65°C; add 51g of methyl ethyl ketone oxime dropwise between 65-75°C, and isocyanate Control the acid value to 160; add 29g of ethylene glycol methyl ether, heat up to 120°C after adding, keep warm for 2h, control the isocyanate value to 28±1, drop the temperature to 100°C, add 15g of trimethylolpropane, stir After 30 minutes, add 17g of methyl isobutyl ketone for dilution, control the isocyanate value below 1, and control the solid content of the curing agent to 90%.

[0047] Preparation of ketimine

[0048] Mix 134g of triethylenetetramine and 180g of methyl isobutyl ketone evenly, then raise the temperature to 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com