Liquid crystal display and manufacturing method thereof

A technology of a liquid crystal display and a manufacturing method, applied in the field of liquid crystal displays, can solve the problems of damage to display elements, incomplete curing of sealant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] Although a series of operations or steps are used to illustrate the methods disclosed herein, the order in which these operations or steps are shown should not be construed as a limitation of the present invention. For example, certain operations or steps may be performed in a different order and / or concurrently with other steps. In addition, not all illustrated operations, steps and / or features must be performed to implement an embodiment of the invention. Furthermore, each operation or step described herein may contain several sub-steps or actions.

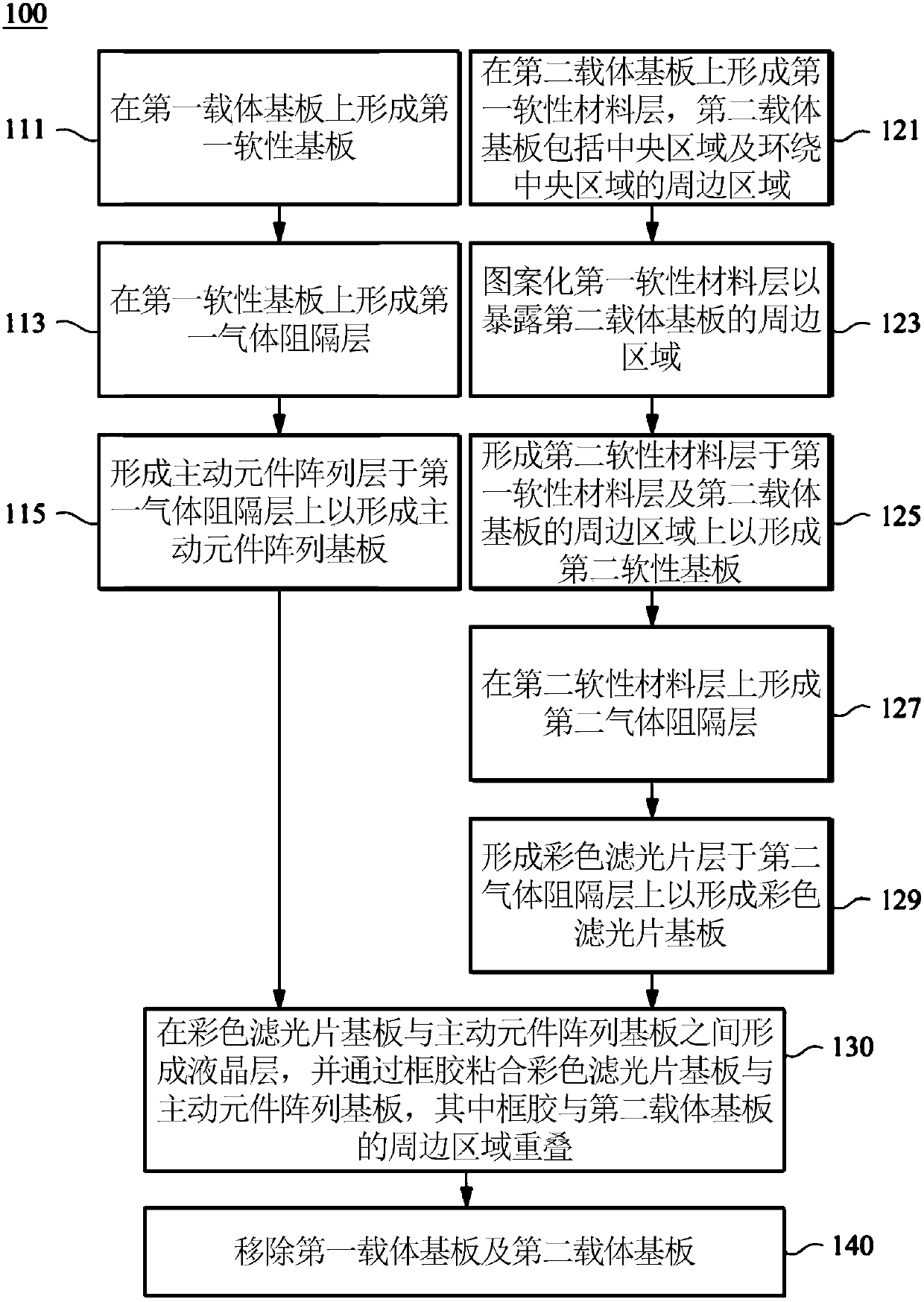

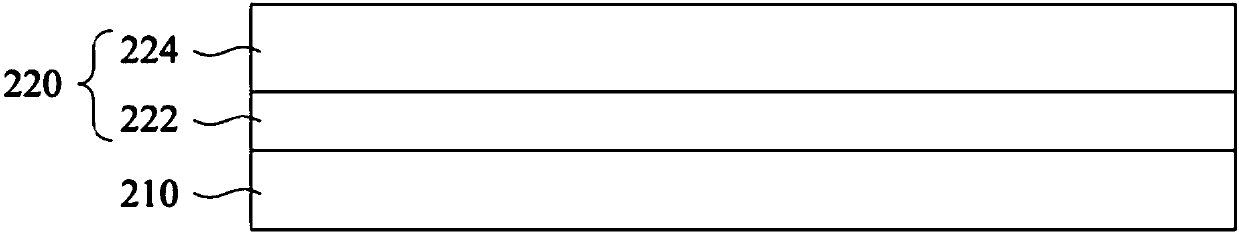

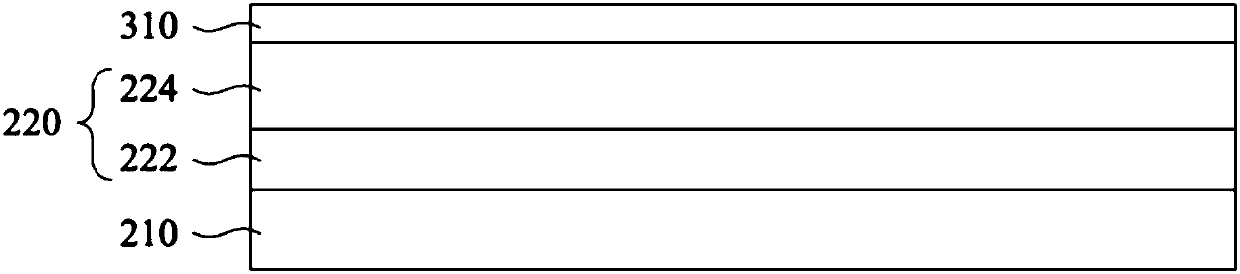

[0026] The invention provides a method for manufacturing a liquid crystal display, please refer to Figure 1 to Figure 11 . figure 1 is a flow chart of a method 100 for manufacturing a liquid crystal display according to some embodiments of the present invention. The method 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com