Hot rolling high-chambering steel plate with tensile strength of 590 MPa and manufacturing process thereof

A technology of tensile strength and manufacturing process, applied in the field of metal materials, can solve the problems of inability to meet the requirements of forming performance and low hole expansion performance, and achieve the effects of good hole expansion rate, high hole expansion rate, and easy production.

Inactive Publication Date: 2010-12-29

BAOSHAN IRON & STEEL CO LTD

View PDF5 Cites 58 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The thickness of high reaming steel is generally not more than 6mm, and the reaming performance of ordinary SAPH carbon-manganese steel plates is often relatively low (≤70%), which cannot meet the formability requirements of some complex-shaped parts of the automobile chassis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

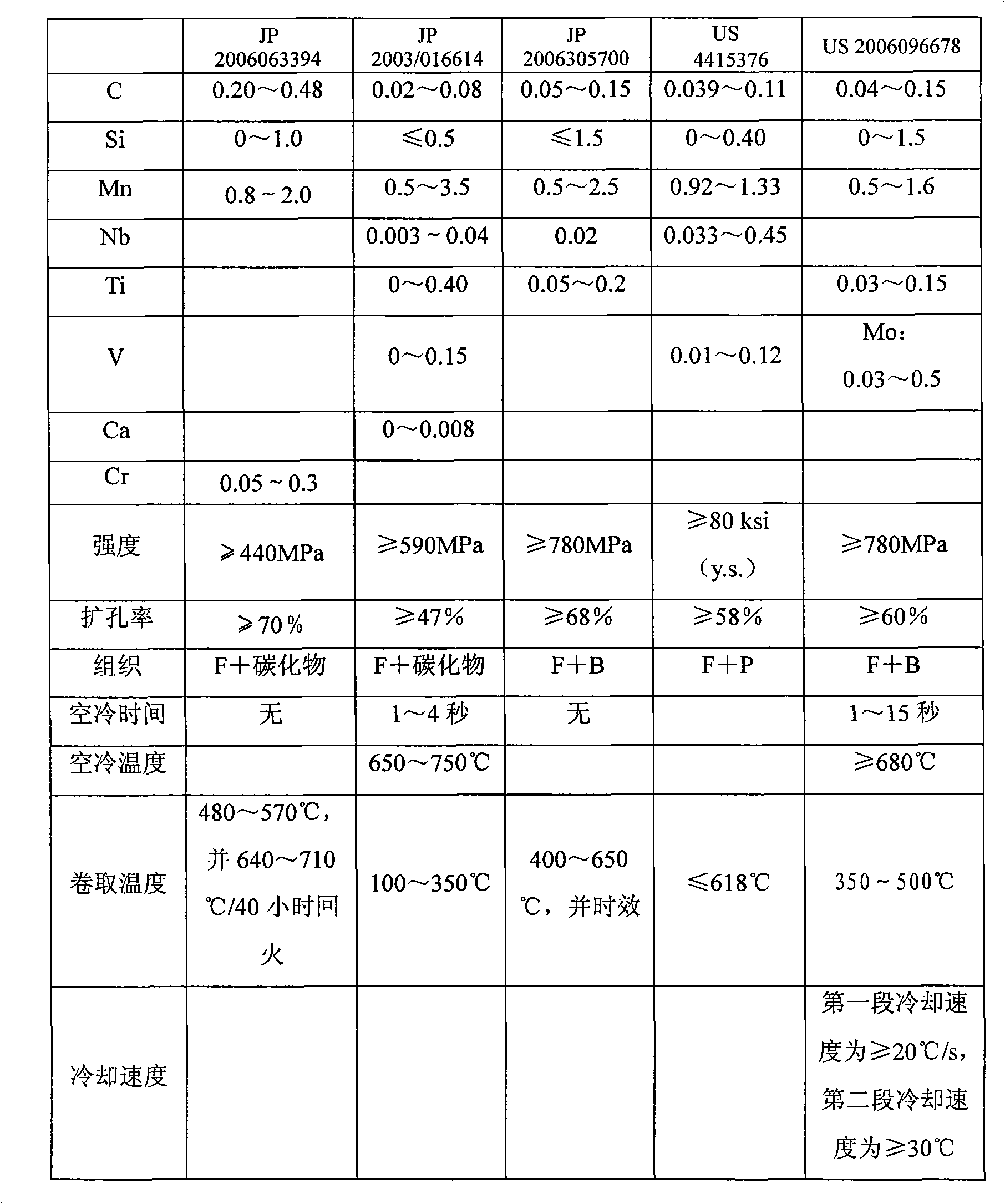

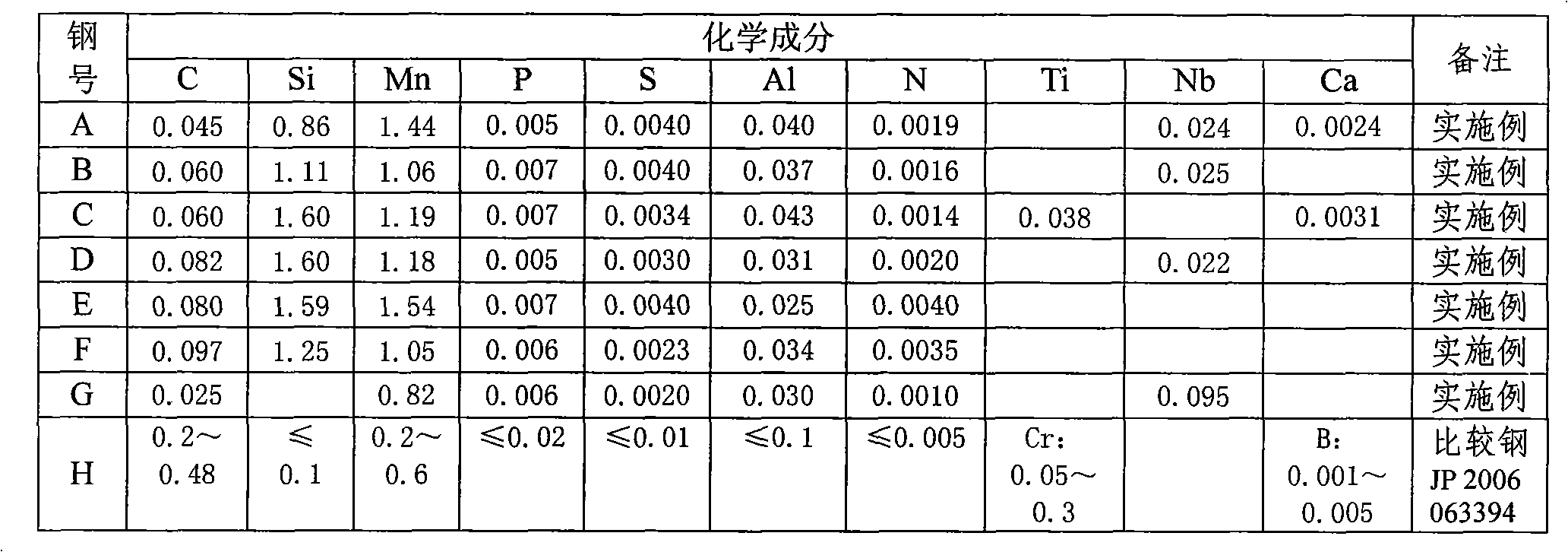

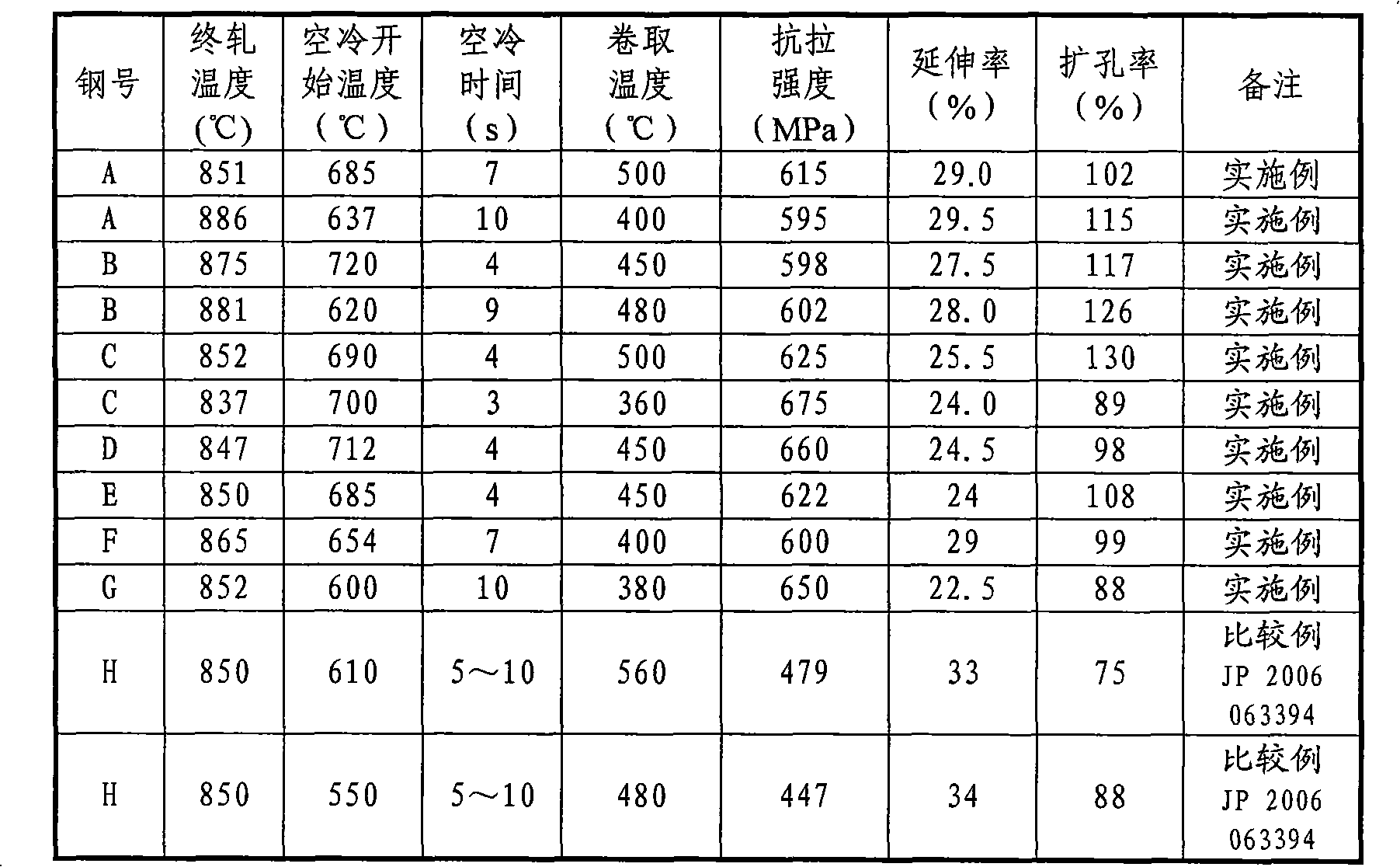

[0040] Table 2 shows the chemical composition of the test steels, steels A to G are the compositions of the steel examples of the present invention, and steel H is the comparative steel of JP2006063394.

[0041] The chemical composition of table 2 embodiment of the present invention and comparative example

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a hot rolling high-chambering steel plate with the tensile strength of 590 MPa. The steel plate comprises the following chemical compositions in percentage by weight: 0.02-0.10 percent of C, 0-1.6 percent of Si, 0.8-2.0 percent of Mn, smaller than or equal to 0.035 percent of P, smaller than or equal to 0.010 percent of S, 0.025-0.060 percent of Al, smaller than or equal to 0.0060 percent of N, 0-0.10 percent of Nb, 0-0.04 percent of Ti, 0-0.0050 percent of Ca and the balance of Fe and unavoidable impurities. The manufacturing process of the hot rolling high-chambering steel plate comprises the following steps of: heating a steel billet at 1,150-1,250 DEG C, and then rolling in an austenitic area, wherein the rolling deformation is larger than 80 percent, and the finish rolling temperature is 830-900 DEG C; cooling the steel plate after finish rolling to 600-750 DEG C at a cooling speed of 50-100 DEG C / s; cooling for 3-10 seconds in the air at a cooling speed of 5-15 DEG C / s; then cooling the steel plate to 350-500 DEG C at a cooling speed of 70 DEG C / s and reeling; and then cooling in the air to room temperature. The steel plate is particularly suitable for manufacturing a chassis component of a car.

Description

technical field [0001] The invention belongs to the field of metal materials, in particular to iron-based alloys containing C, Si, Mn, Nb, Ti, etc. It is a hot-rolled high-hole-expanding steel plate with a tensile strength above 590 MPa without heat treatment and its manufacturing process. Steel plates are especially suitable for making chassis components of cars. Background technique [0002] In recent years, due to the increasing awareness of human environmental protection, reducing the fuel consumption of cars and reducing CO 2 Emissions have become a common global voice, among the various measures to achieve this goal, vehicle weight reduction is a very effective means. This global trend and the emphasis on automobile safety have brought about the demand for various advanced new steel materials with high strength and good processing performance. [0003] Hot-rolled steel plates are mainly used for car chassis, wheels, suspension and their surrounding parts, and its wei...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/14C21D8/02

Inventor 庞厚君陈兴张建苏

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com