Guide rod type diesel pile hammer with vertical landing gear

A technology of landing gear and piling hammer, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as deformation and damage of piling frames, external force wire rope breakage, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

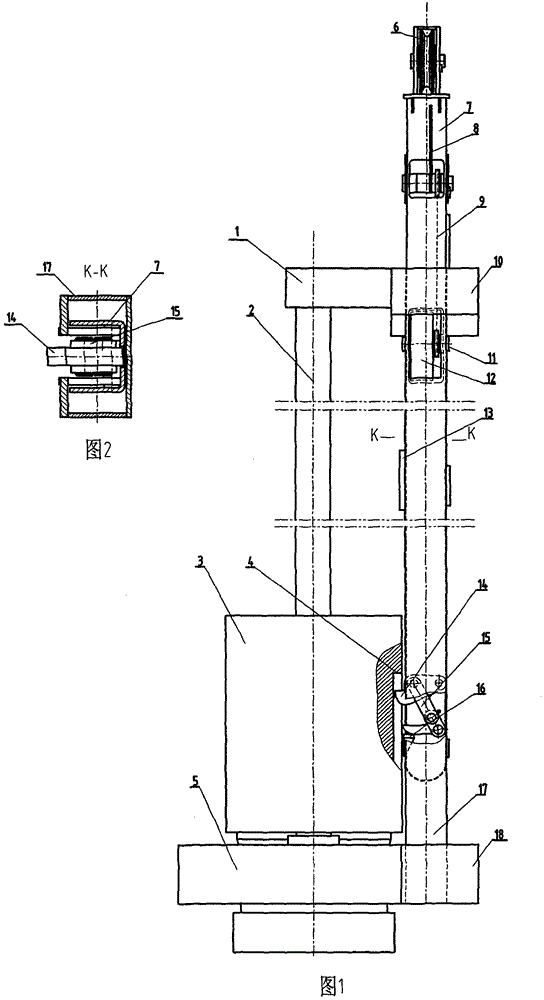

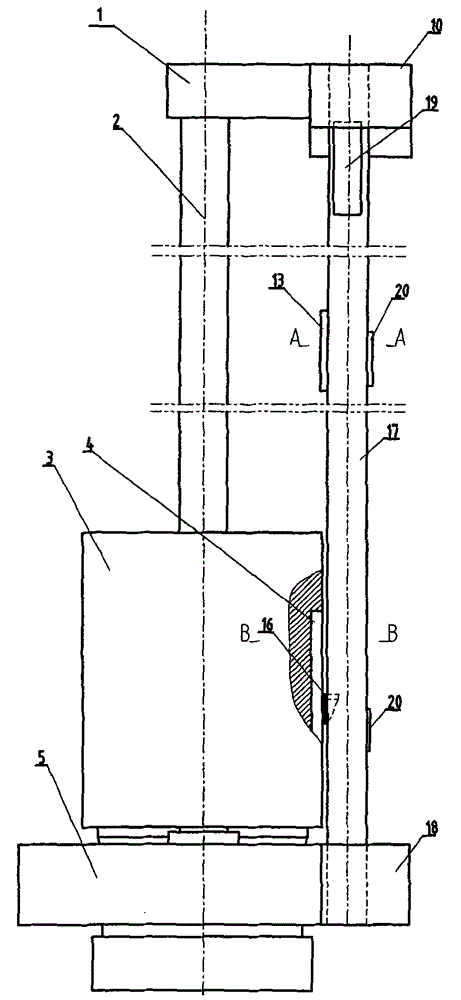

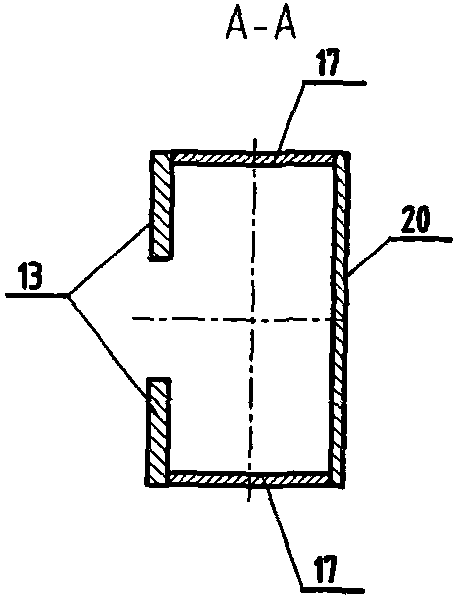

[0019] exist figure 1 , figure 2 In the shown guide rod diesel piling hammer with vertical landing gear, the piling hammer includes a top beam 1, a guide rod 2, a cylinder hammer 3 and a piston 5, and two guide rods 2 are arranged parallel to each other. The top beam 1 is fixedly installed on the upper ends of the two guide rods 2, the lower end of the guide rod 4 is fixedly installed on the piston 5, and a pile cap is installed on the bottom surface of the piston 5, and the cylinder hammer 3 is located between the top beam 1 and the piston 5, And the cylinder hammer 3 can slide and bounce up and down along the two guide rods 2, and an upper guide claw 10 and a lower guide claw 18 are respectively fixedly arranged on the same outer side of the top beam 1 and the piston 5. Different from the prior art, the undercarriage 7 is vertically arranged on the outside of the piling hammer cylinder hammer 3, and the position is on the same side as the upper guide claw 10 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com