Physical foaming cement well cementation technology and matching system

A technology of cement cementing and physical foaming, which is applied to cement mixing devices, wellbore/well components, mixing methods, etc. Cost, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

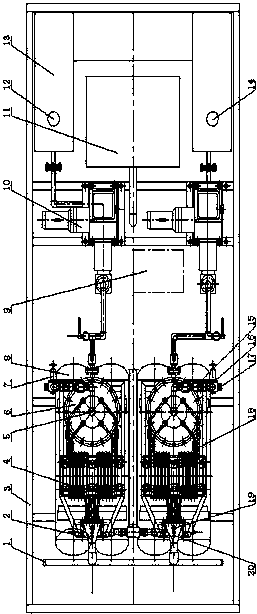

[0011] Such as figure 1 As shown, the physical foaming cement cementing technology and supporting system include a frame, a liquid mixing tank 13 fixed on the frame, an air compressor 11, a metering pump 10, a gas storage bottle 8, a foaming tank 6, and a foam mixer 4. All-in-one joint 2, foam output port 1, the frame is a cuboid structure, the right end of the frame is fixed with a U-shaped mixing tank 13, and the two U-shaped ends of the U-shaped mixing tank 13 are respectively connected to two sets of metering pumps 10 through valve pipes 3 , through two sets of metering pumps 10, the U-shaped liquid mixing tank 13 is connected to the two foaming tanks 6 respectively, and a set of air compressor 11 is connected to two sets of gas storage cylinders 8 through the valve pipeline 3, and the outlets of the two sets of gas storage cylinders 8 pass through The right safety valve 16 and the electromagnetic pressure regulating valve 15 are also connected to the foaming tank 6 pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com