Creep test device

A creep test, screw technique, applied in the direction of testing the strength of materials by applying stable tension/pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

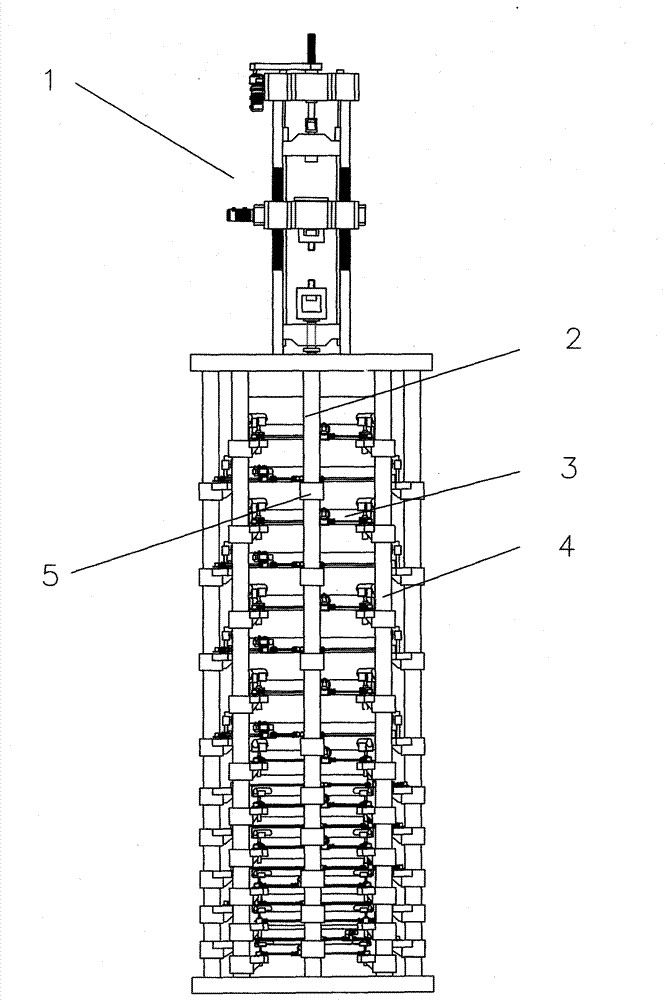

[0017] figure 1 A schematic diagram of the structure of the force sensor calibration device is shown. Such as figure 1 The shown device includes a loading part 1 , a boom 2 and a weight synchronous loading and unloading device 3 .

[0018] The loading part 1 is used to apply load to the pressure or tension sensor to be calibrated, and its lower end is connected to the suspender 2; on the suspender 2, a plurality of weight driving mechanisms 3 are pierced.

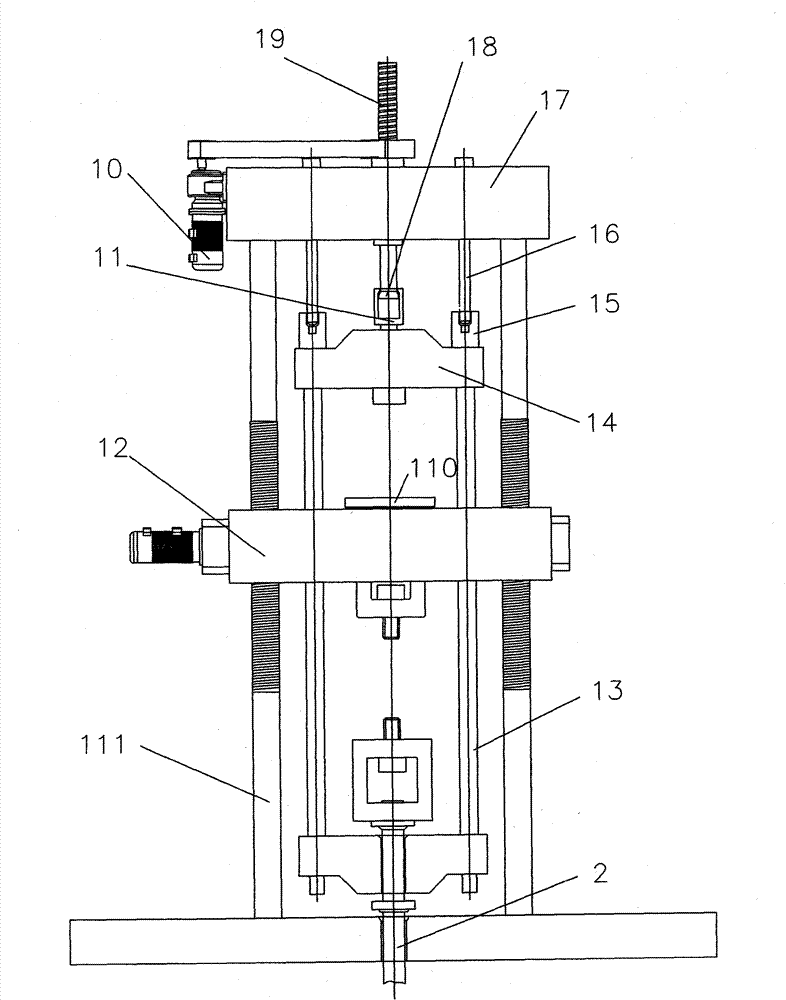

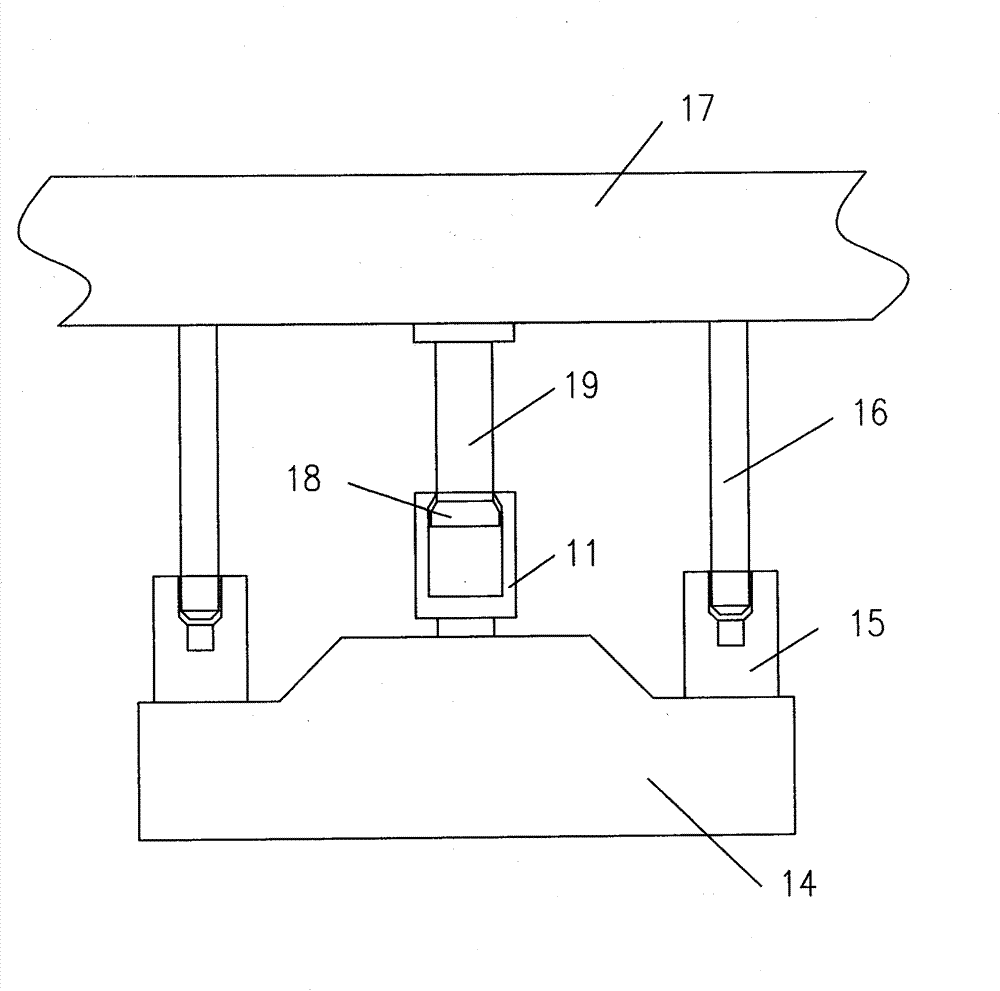

[0019] figure 2 It is a schematic diagram of the structure of the loading part. Such as figure 2 As shown, the loading part 1 includes a motor 10 , a moving beam 12 , a reverse frame mechanism 13 and a screw 19 .

[0020] The moving beam 12 can move vertically along the threaded column 111 of the loading part 1 and can be fixed at any position of the thread, which has a tray 110 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com