Control device, control model adjusting device and control model adjusting method

A technology of control model and control device, applied in the direction of control/regulation system, adaptive control, general control system, etc., can solve the problem of difficulty in setting, construction and adjustment of values, such as excessive labor, and achieve the effect of rapid correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach example

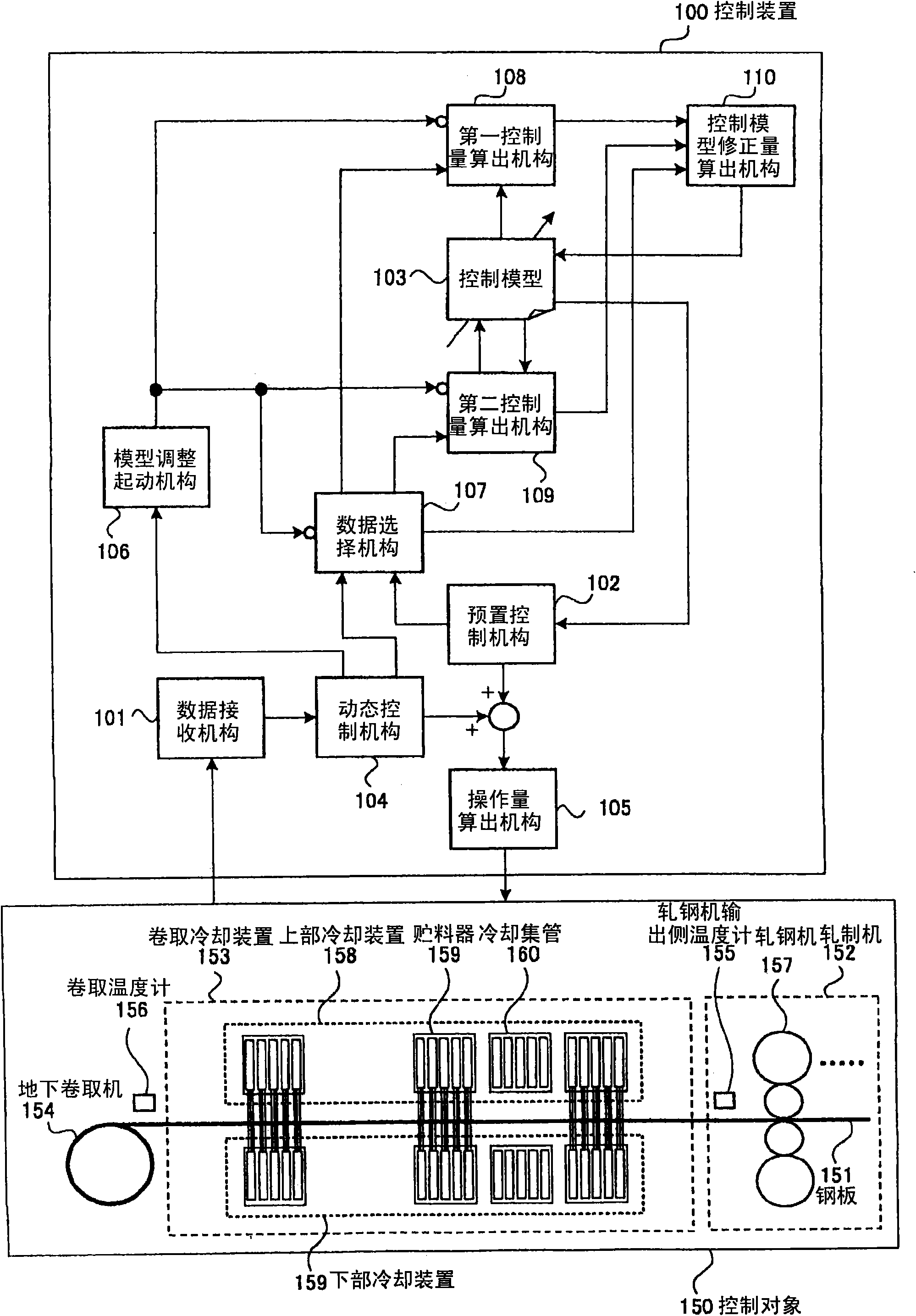

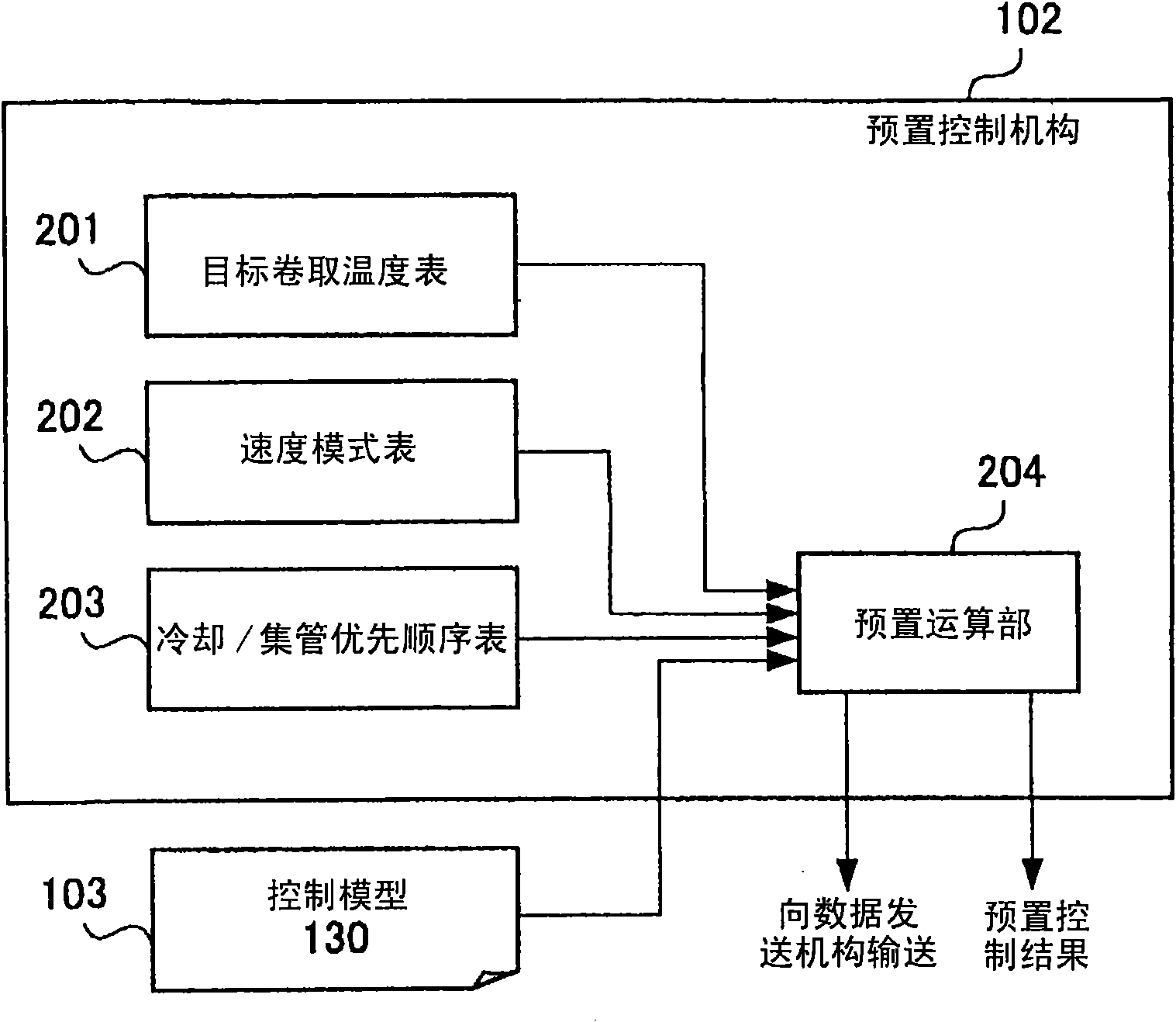

[0079] figure 1 It is a block diagram showing a schematic configuration of the first embodiment of the present invention (hereinafter referred to as "this example"). In addition, each function is demonstrated by a block, but the functional block described as "...mechanism" consists of one or more computers as a whole, and is realized by software. The control device 100 receives various signals from the control object 150 and outputs various control signals for controlling the control object to the control object 150 .

[0080] First, the outline of the control object 150 will be described. In this example, the control object 150 represents an example of a coiling temperature control facility for hot rolling. The control object 150 in this example is a rolling operation in which the steel plate 151 rolled by the rolling mill 157 of the rolling mill 152 at about 900° C. is cooled to a predetermined temperature in the coil cooling device 153 and then coiled in the down coiler 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com