Device for separating lead frame from flow channel

A separation device and lead frame technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of insecurity, low product qualification rate, low efficiency, etc., and achieve the effect of improving safety and improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

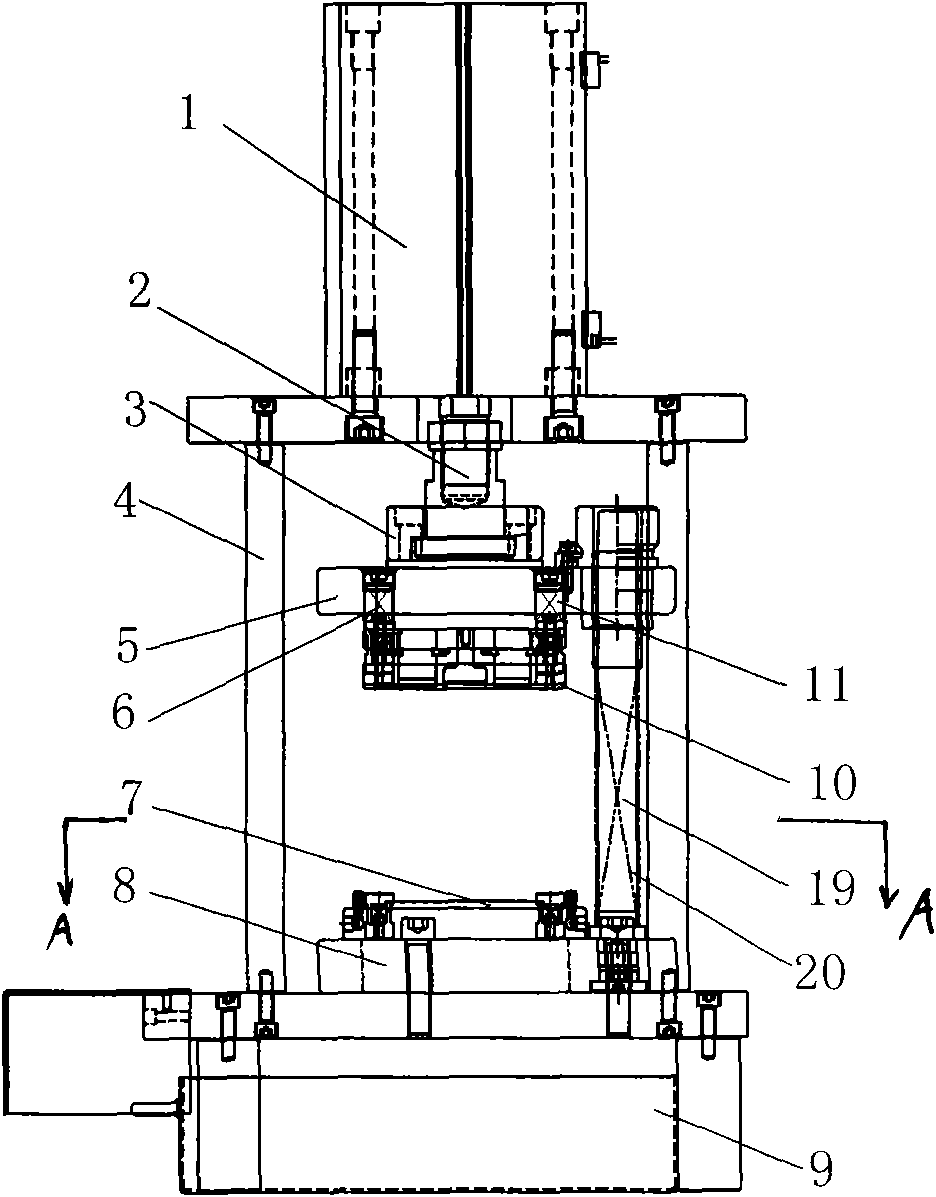

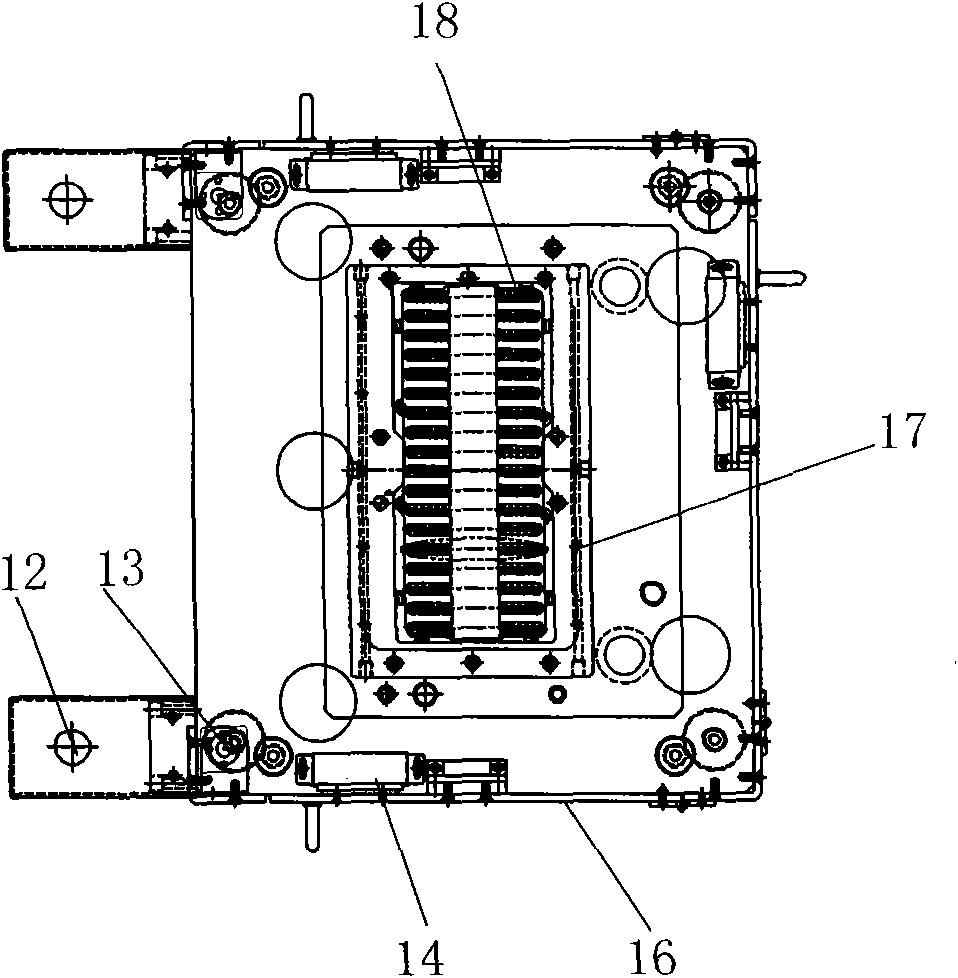

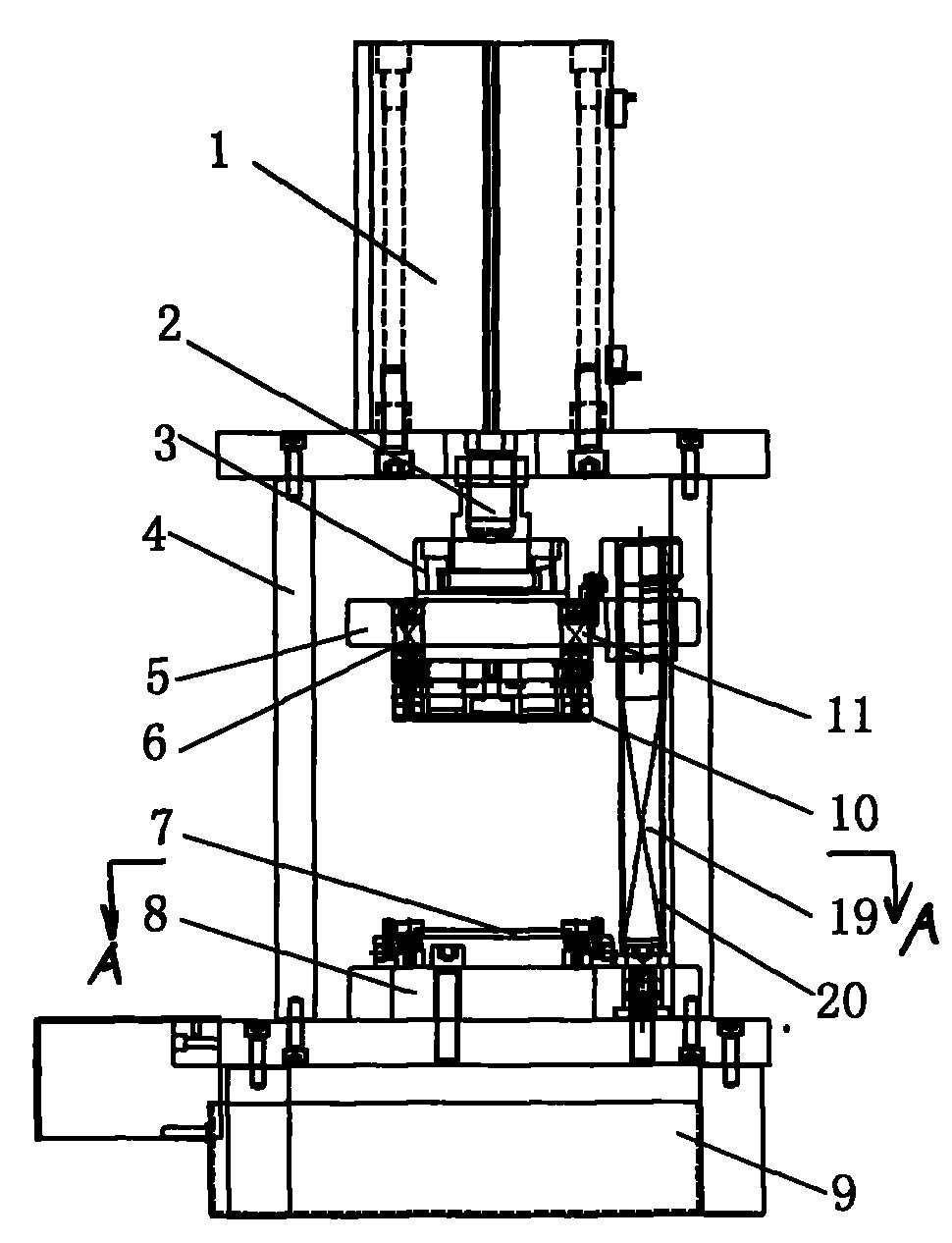

[0013] The lead frame and flow channel separation device of the present invention, such as figure 1 As shown, it includes a closed frame-shaped frame 4, a separating mold used to separate the lead frame 18 from the runner, and a cylinder 1 to provide power. The frame 4 is provided with movable doors 16 on both sides. In order to make the movable door 16 closed, it can not be easily opened such as figure 2 As shown, a magnetic bump 14 is provided under the frame 4, and when the movable door 16 is closed, the magnetic bump 14 is attracted.

[0014] The separating mold is composed of a movable mold and a fixed mold adapted to it. The movable mold includes a mounting plate 5 and a punch 10. The mounting plate 5 is provided with four guide shafts 11, and the punch 10 is provided with a through hole to cooperate with the guide shaft 11 , The punch 10 is hung on the guide shaft 11, the guide shaft between the punch 10 and the mounting plate 5 is sleeved with a compression spring 6. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com