Heat exchanger

A heat exchanger and header technology, applied in the field of parallel-flow heat exchangers, can solve the problems of increasing the space of the heat exchanger 1, difficult to achieve equalization of refrigerant flow, and reduction of refrigerant flow, etc., so as to achieve equal refrigerant flow. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

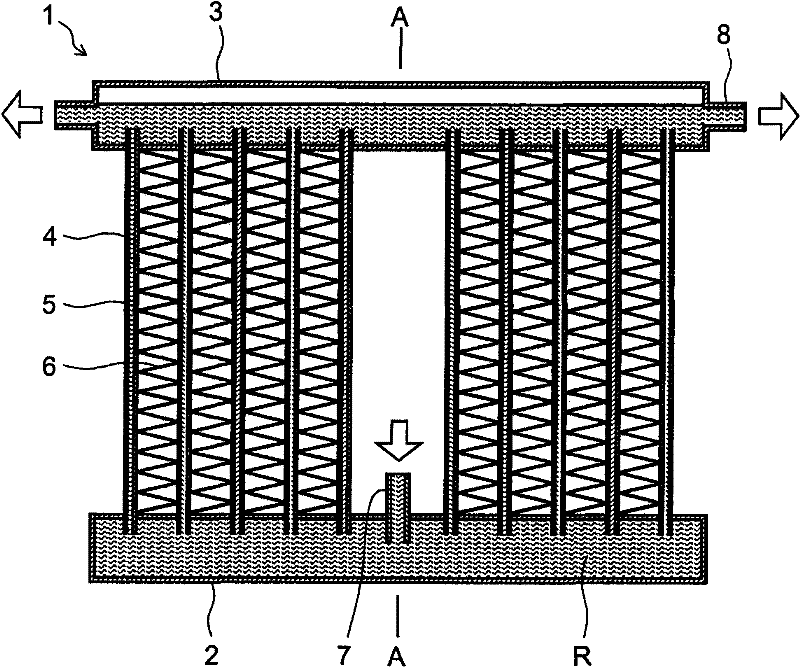

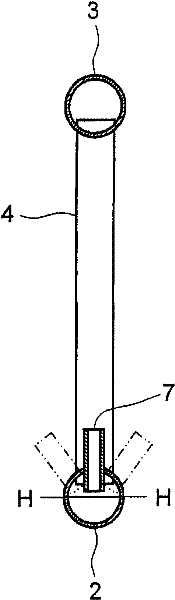

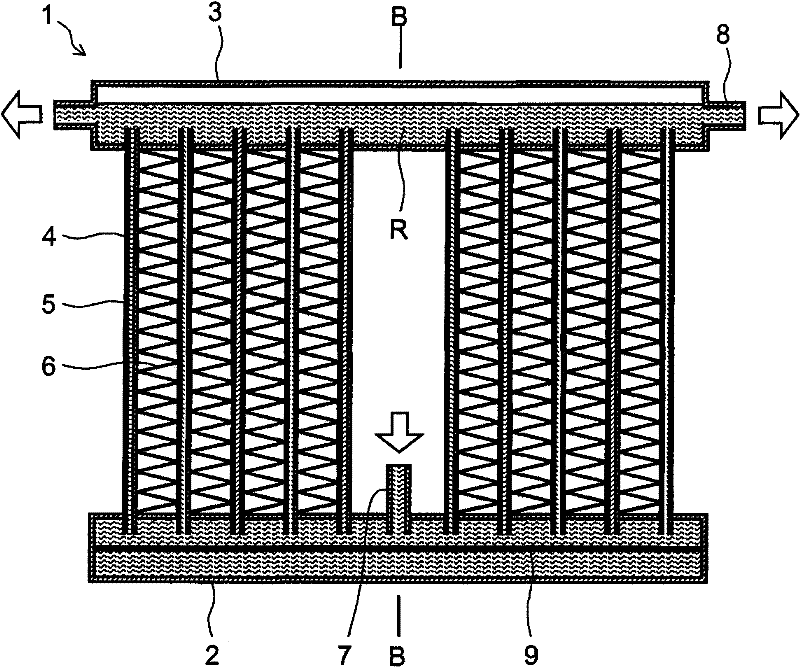

[0052] The following is based on figure 1 , figure 2 A first embodiment of the present invention will be described. Since the heat exchanger 1 of the first embodiment has many parts and Figure 16 The conventional structure shown is the same, so the same part adopts the same Figure 16 The same reference numerals are used, and repeated explanations are omitted. The first embodiment and Figure 16 The difference of the conventional structure is the arrangement method of the inlet pipe 7. The inlet pipe 7 is arranged away from the outlet pipe 8 . Since the outlet pipe 8 is located at both ends of the upper header 3 , the central portion of the lower header 2 is located away from the outlet pipe 8 . Although so far with Figure 16 However, in the present invention, instead of connecting the inlet pipe 7 to the lower header pipe 2 from below, it is connected to the lower header pipe 2 from above. In addition, in order to avoid interference between the inlet pipe 7 and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap