Inductor and method for production of an inductor core unit for an inductor

An inductive coil and coil technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor components, inductors, etc., can solve the problem of enhancing sound, reducing the working duration of the inductive coil, and reducing the mechanical stability of the inductive coil core unit and other problems to achieve the effect of improving working duration, prolonging working duration and life, and low sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

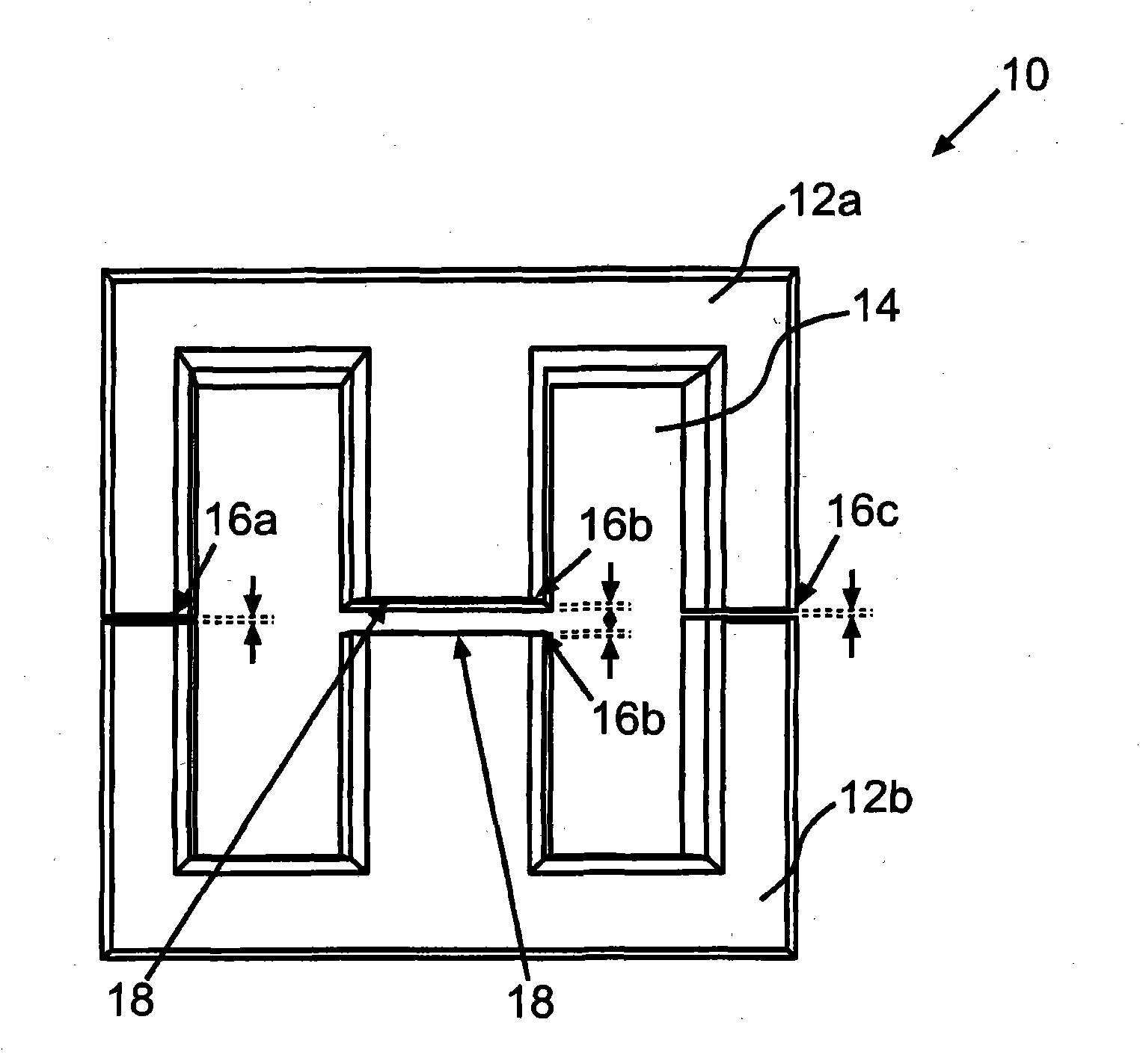

[0022] figure 1 A cross-sectional view of the side of an induction coil core unit 10 is shown, which can be used for an induction coil. The inductor core unit 10 comprises an inductor core 12 comprising two inductor core parts 12a, 12b which are E-shaped in cross section. The inductor coil core parts 12a, 12b are arranged around a double T-shaped coil body 14 in cross-section, which serves on the one hand to increase the strength of the inductor coil when the coil body is wound several times with an electrical conductor not shown. inductance. Between the inductor coil core parts 12a, 12b and the coil body 14 there is an air gap 16 which has different gap widths in different sections 16a-16c. For mechanical stabilization, a filler material 18 is introduced into the section 16 b of the air gap 16 , which forms the middle path of the inductor coil. The sections 16a, 16c of the air gap 16 which form the outer legs of the two inductor core parts 12a, 12b (which here have a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com