Cutter suction dredge reamer device

A technology of cutter suction dredger and reamer, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. It can solve the problems of being easily entangled and blocked by garbage, and achieves convenience The effects of detection and maintenance, increasing work efficiency, and convenient manual reversing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

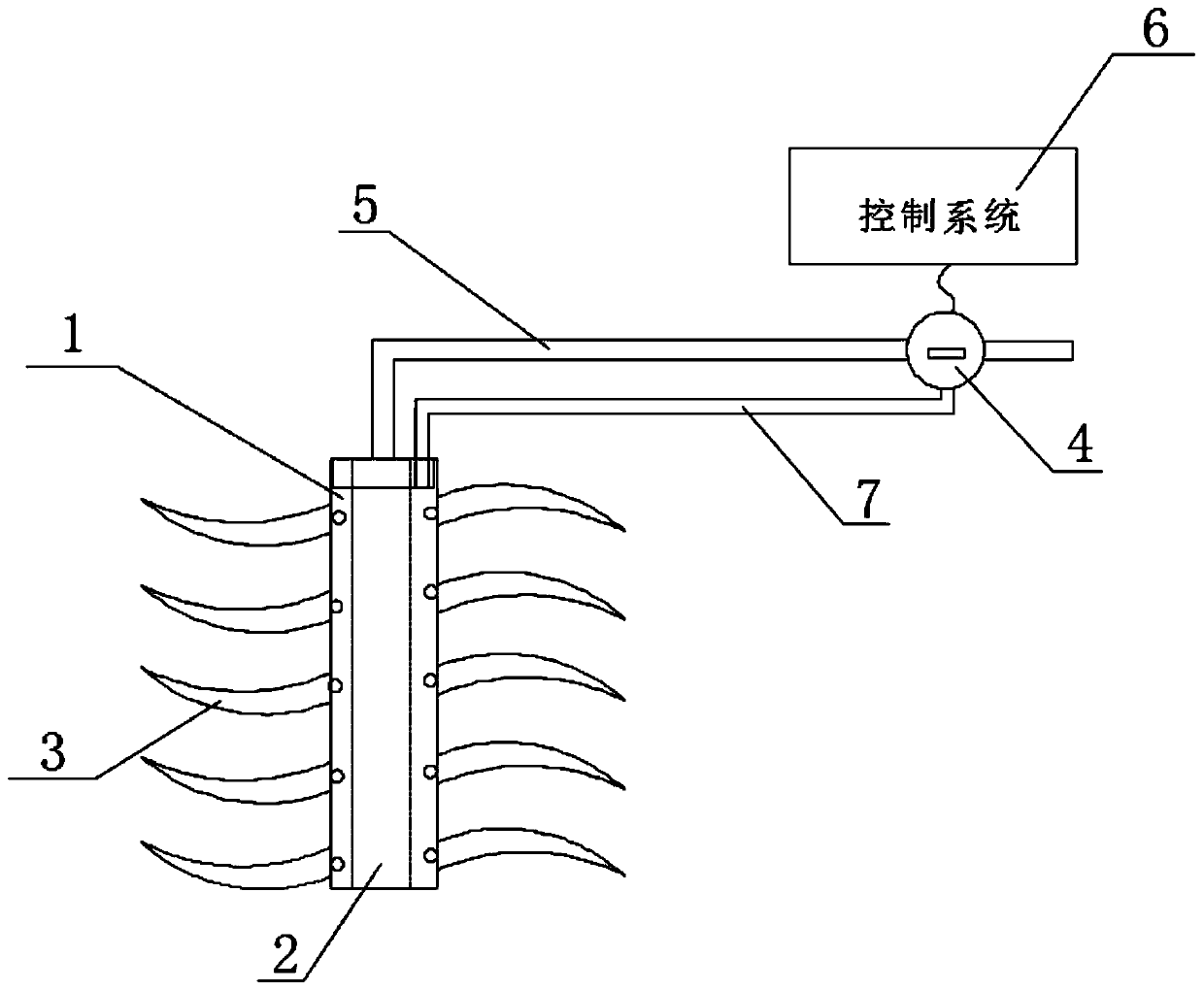

[0028] Such as figure 1 As shown, this embodiment provides a cutter suction dredger reamer device, including a reamer head 3, a mud pump 2, and a control system 6; a plurality of reamer heads 3 are located on the outer periphery of the reamer cylinder; The mud pump 2 is located inside the reamer barrel; the reamer barrel is rotated around the mud pump 2; the mud pump 2 is connected to the delivery pipeline 5; the mud pump 2 is electrically connected to the control system 6; A gap is provided, and the gap is a compression chamber 1, and a plurality of holes are arranged on the surface of the compression chamber 1, and a steering valve 4 is arranged on the delivery pipeline 5, and the branch end of the steering valve 4 is connected to the return water pipeline 7, The return water pipe 7 is connected to the compression chamber 1 and communicates with the inside of the compression chamber 1 .

[0029] During specific implementation, the return water pipe 7 is connected to the top...

Embodiment 2

[0031] During specific implementation, the steering valve 4 is a manual valve. The steering valve 4 is located near the water outlet on the delivery pipeline 5 .

[0032] Steering valve 4 is a ball valve or a butterfly valve etc., as long as the junction that can realize the function of protecting the nib is within the protection scope of the present invention, the outer sidewall of the pen cap can be polygonal or circular.

Embodiment 3

[0034] On the basis of Embodiment 1, the steering valve 4 is an electric valve, and the steering valve 4 is electrically connected to the control system 6, and the control system 6 includes a control switch of the steering valve 4 . When the electric valve is used, it is usually enough to directly connect to the transformed power supply, and the electric valve with a built-in transformer can be directly connected to the power supply, which is convenient for implementation. Electric valves are usually composed of electric actuators and valves. The electric valve uses electric energy as power to drive the valve through the electric actuator to realize the switching action of the valve. So as to achieve the purpose of switching the pipeline medium.

[0035] Solenoid valve can also be used. Solenoid valve is a type of electric valve; it uses the magnetic field generated by the electromagnetic coil to pull the valve core, thereby changing the on-off of the valve body. When the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com