Sliding rail return mechanism

A slide rail and outer slide rail technology, which is applied to furniture parts, household appliances, drawers, etc., can solve the problems of many components of the automatic closing device, complex overall structure, and expensive manufacturing process, and achieve fast assembly, cost saving, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

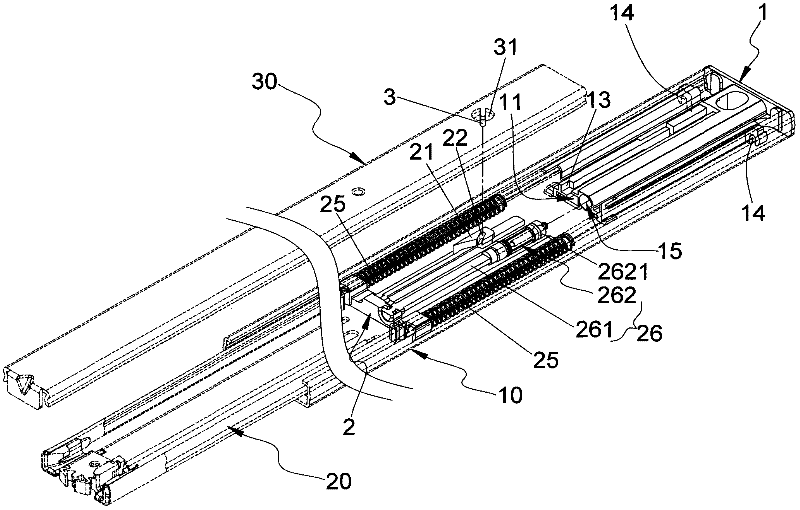

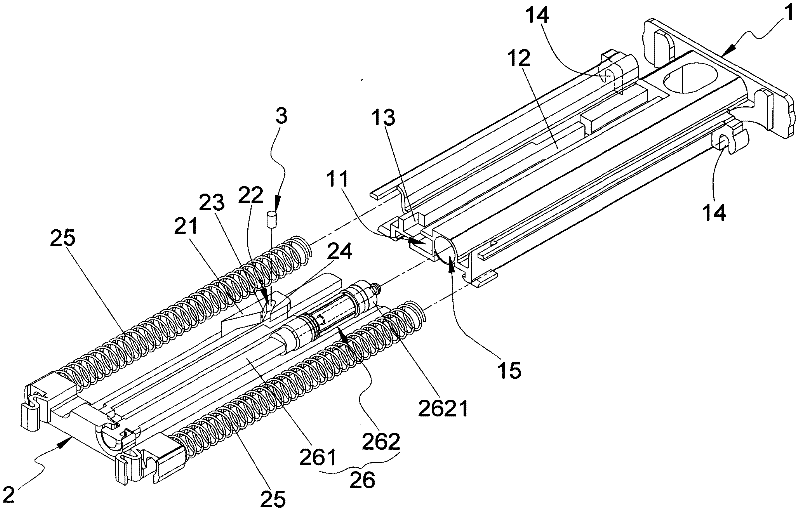

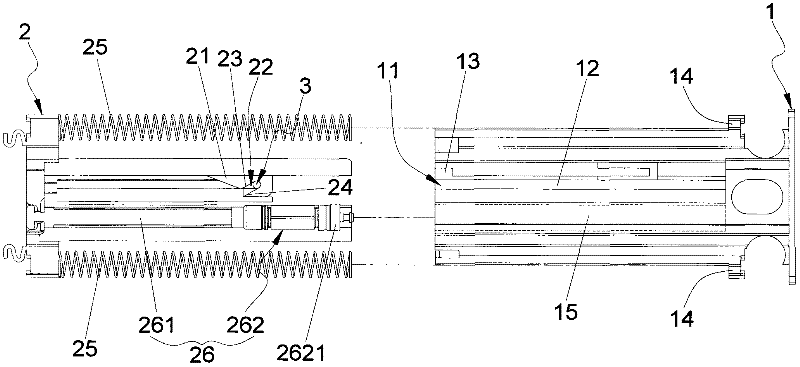

[0034] In order for your examiner to easily understand the other features and advantages of the present invention and the effects achieved, the detailed description of the present invention is hereby accompanied by the accompanying drawings:

[0035] see figure 1 , figure 2 As shown, the present invention provides a sliding rail return mechanism, which includes:

[0036] An outer slide rail 10, one end of the outer slide rail 10 is provided with a fixed seat 1, and the fixed seat 1 is provided with an accommodating space 11, and one side of the accommodating space 11 is provided with a groove 12, and the groove 12 is compatible with the accommodating The spaces 11 are connected, and one end of the fixed seat 1 is provided with a notch 13, the notch 13 is arranged on one side of the accommodating space 11, the notch 13 is on the same side as the groove 12, and the two sides of the fixed seat 1 are provided with There is a fixing part 14, which can be a clamping mouth, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com