Damped type tyre lowering device

A damping and tire technology, which is applied in the field of damping tire landing devices, can solve the problems of poor vertical space utilization, affecting work efficiency, and poor tire flow, so as to improve space utilization, improve work efficiency, and highlight the essence effects of sexuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

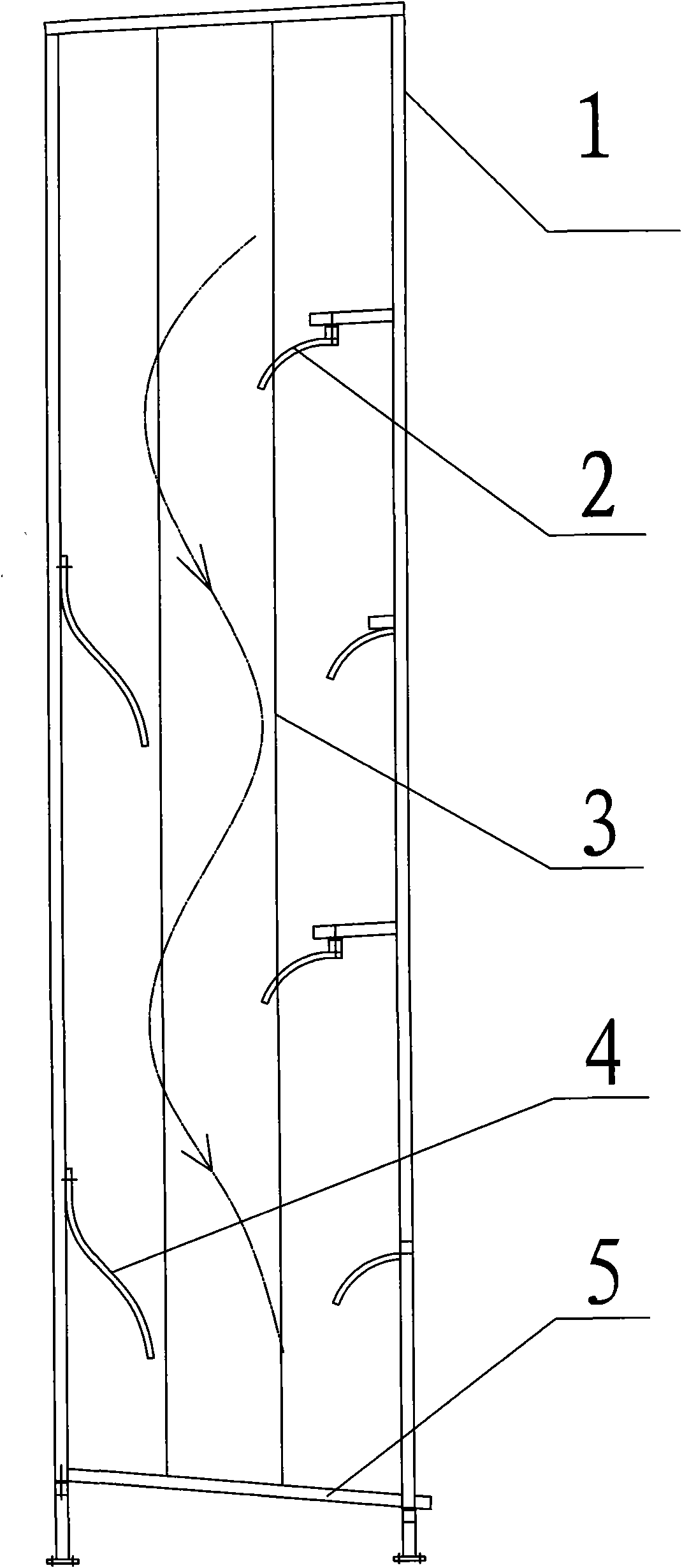

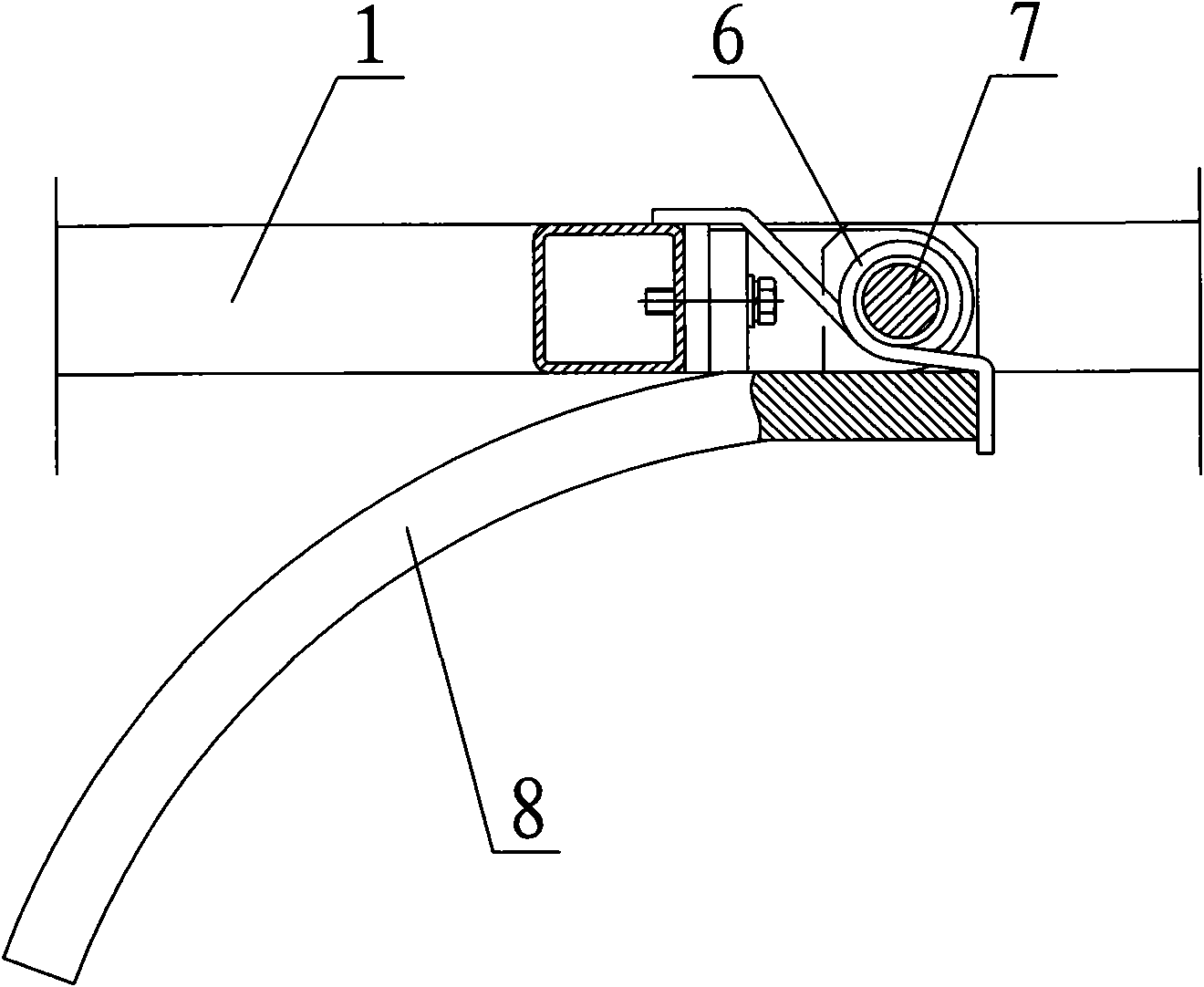

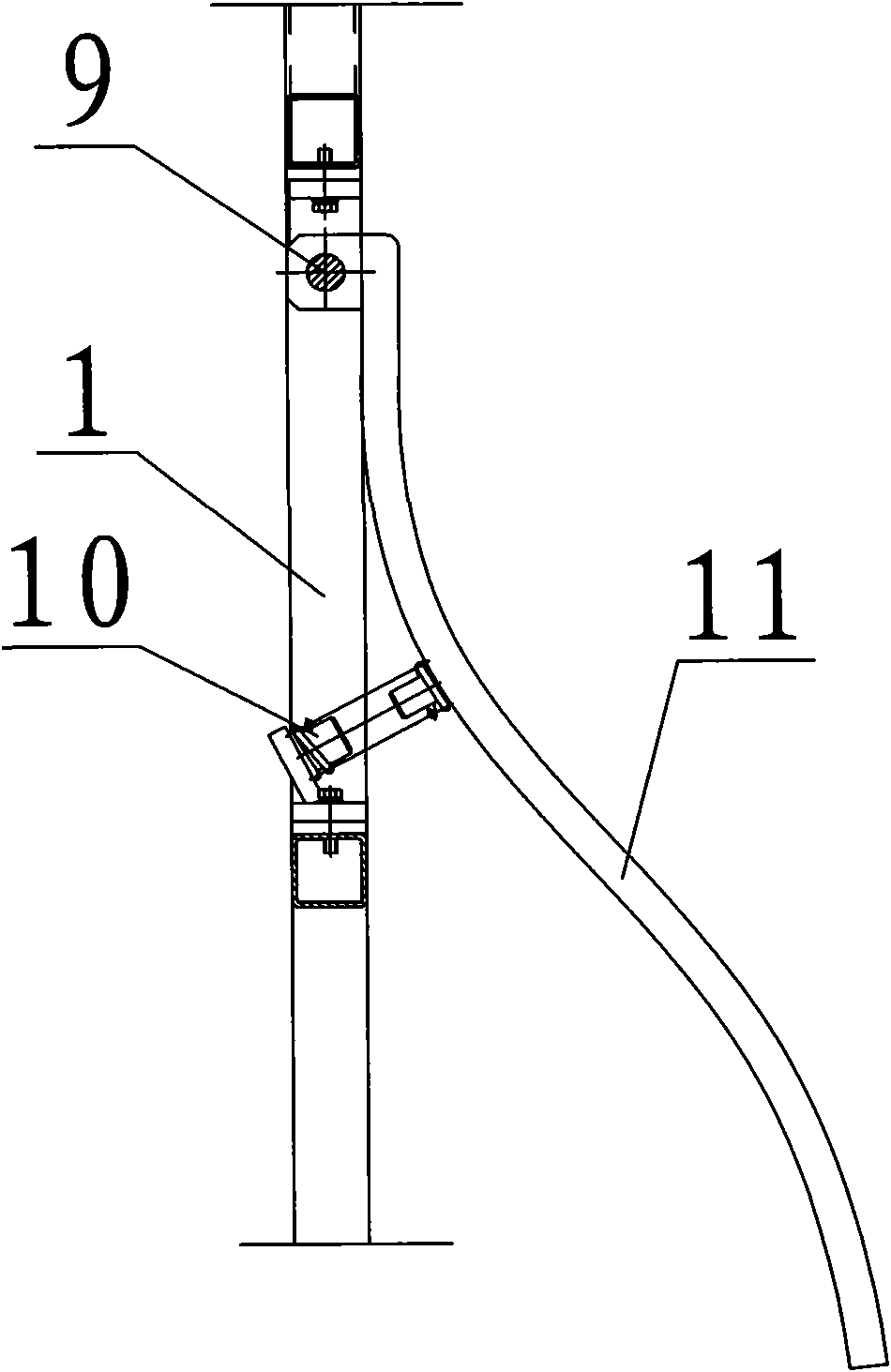

[0019] A damping type tire drop device, such as figure 1 and Figure 4 As shown, it includes a guide frame 1 that can be connected to the outlet end of the tire storage device 13, and an elastic damping mechanism is arranged on the inner wall of the guide frame 1. The elastic damping mechanism can effectively buffer the falling speed of the tire 14, so that the tire 14 is gently whereabouts. The bottom end of the guide frame 1 is provided with an output guide plate 5, the output guide plate 5 is an inclined guide surface, and its oblique direction faces the tire conveyor 15, and the fallen tire 14 rolls to the tire conveyor 15 along the output guide plate 5 and is output. There will be no backlog of tires 14, thereby avoiding the mutual extrusion of tires 14 and preventing the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com