Suspension rope type elevator

A sling type and sling technology, which is applied in the field of sling detection devices, can solve problems such as sling detection, and achieve the effects of high detection reliability, strong bearing capacity, and excellent installation workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

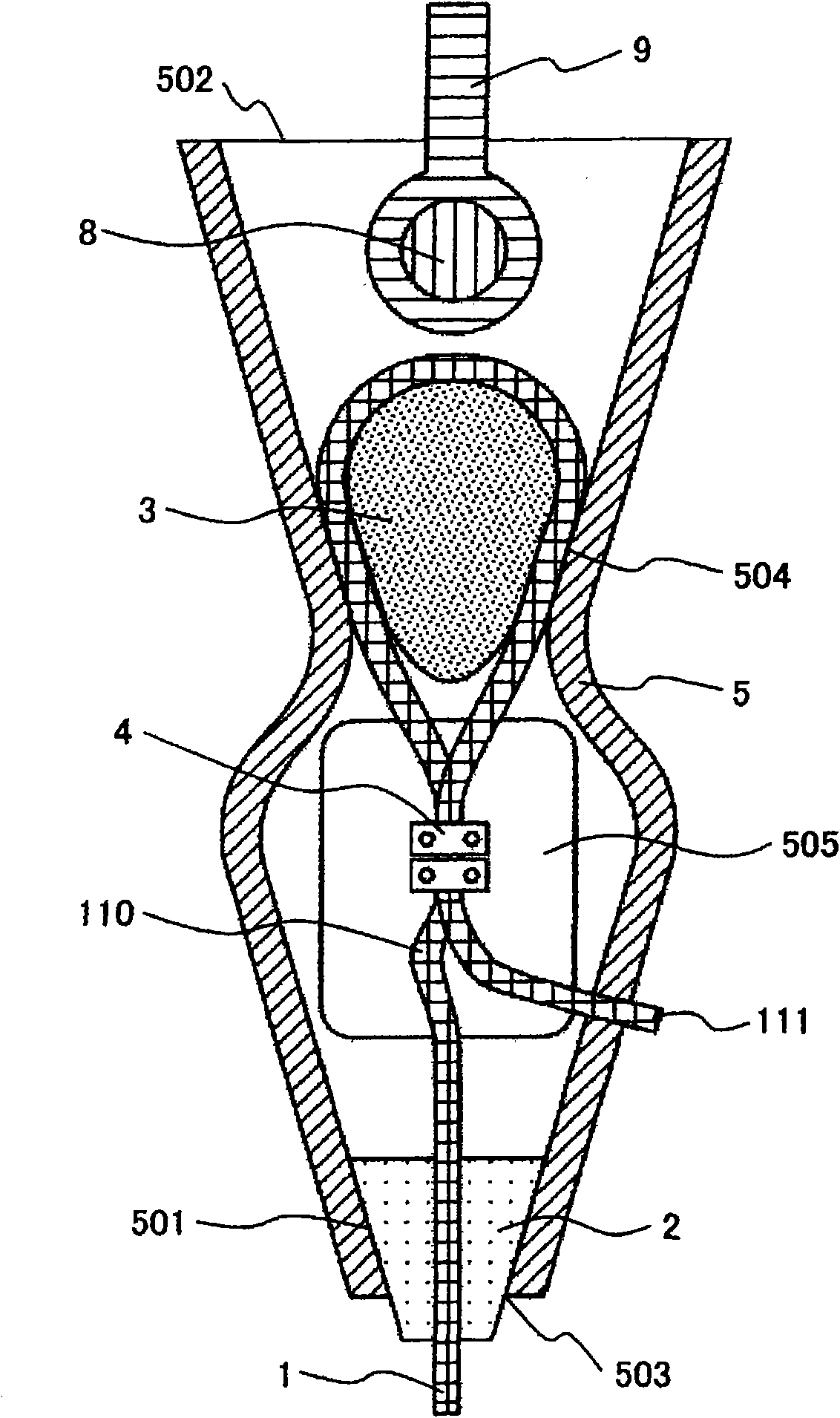

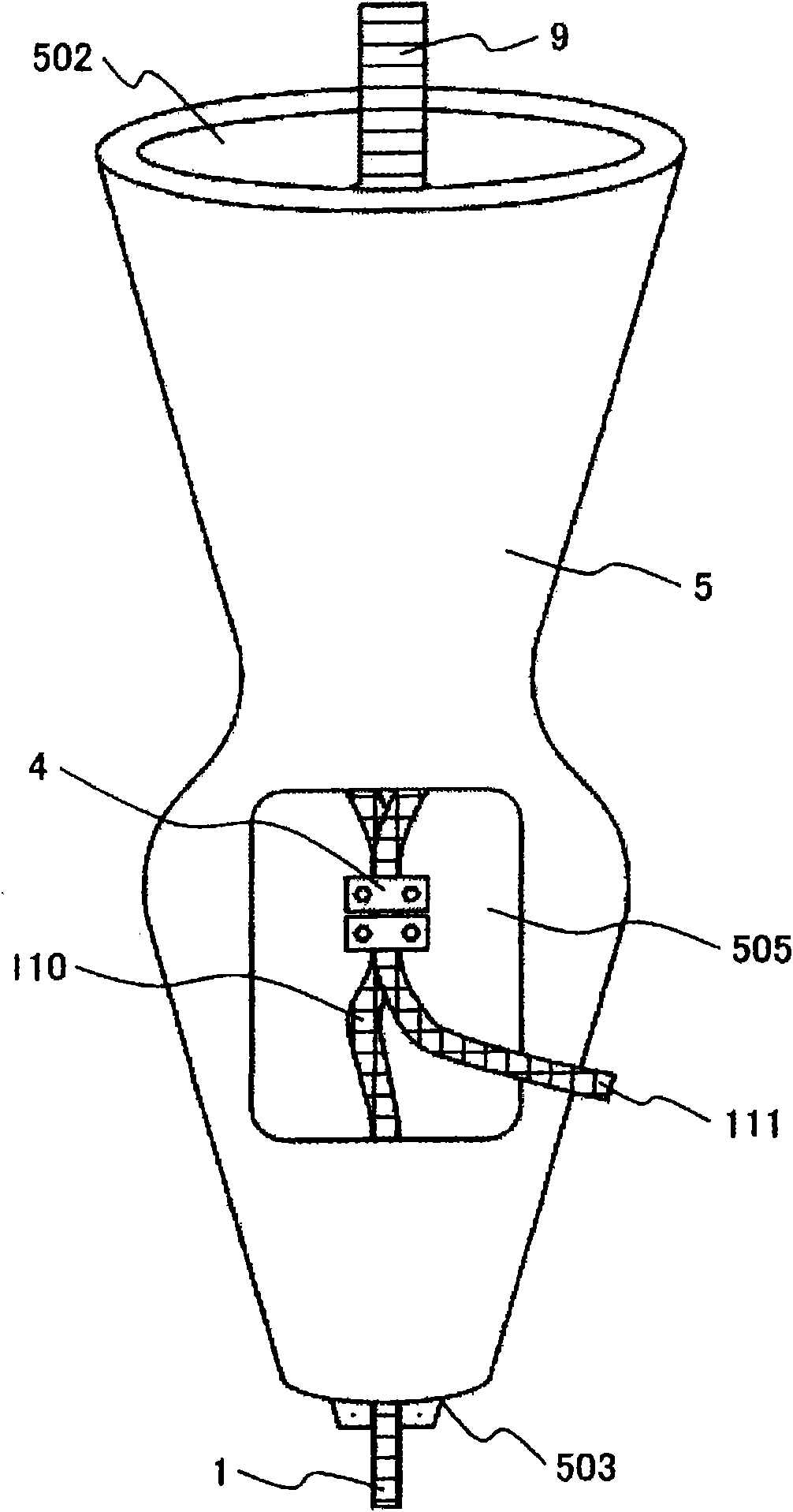

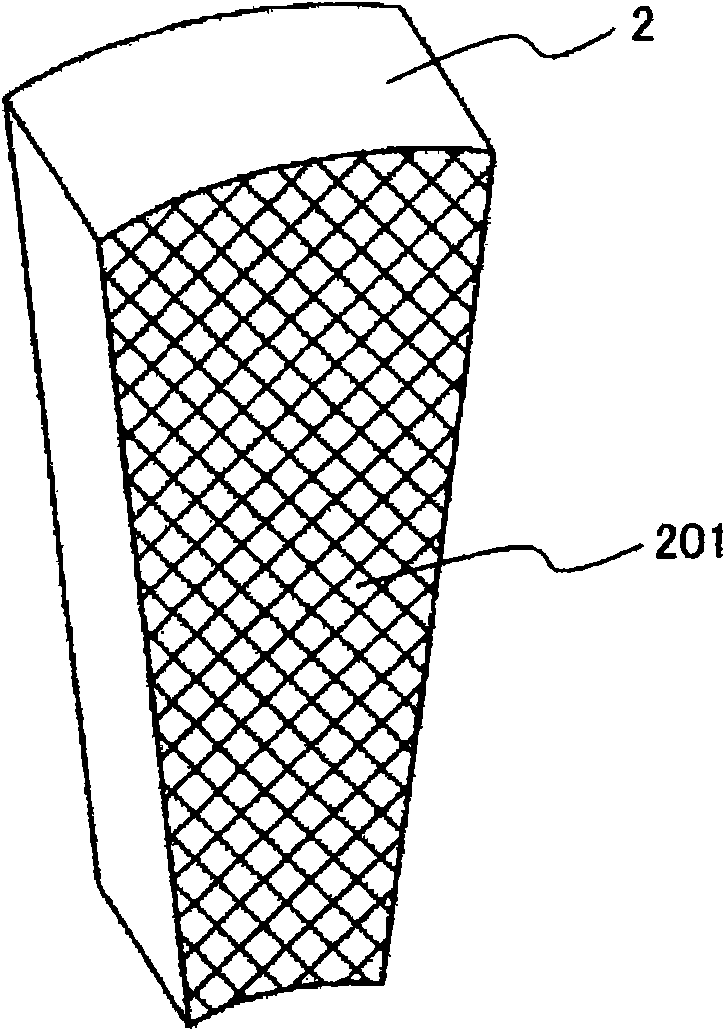

[0059] Such as figure 1 As shown, the sling holding device of the first embodiment is composed of a clamping wedge member 2 , a winding wedge member 3 , a clamp 4 for binding the sling 1 , and a sleeve 5 . Wherein, the clamping wedge member 2 is divided into several parts and is arranged to clamp the sling 1, and the coiling wedge member 3 winds the sling 1 on itself, thereby in the sleeve The sling is clamped between the sleeve 5 and the coiled wedge member 3 , and the clamped wedge member 2 , the coiled wedge member 3 , and the jig 4 are inserted into the sleeve 5 . The top of sleeve 5 is equipped with pin 8 and collar bar 9, as Image 6 and Figure 7 As shown, the sling retaining device is fixed to the wall of the elevator car, counterweight or hoistway. In addition, if figure 1 As shown, the sleeve 5 has a through hole 505 into which the clamping wedge member 2 is inserted, a large opening 502 into which the winding wedge 3 is inserted, and a small opening 503 into whi...

Embodiment 2

[0072] Figure 8 It is a cross-sectional view showing a second embodiment of the wire holding device according to the present invention. exist Figure 8 in, with the above figure 1 The same parts are represented by the same symbols.

[0073] Such as Figure 8 As shown, the sling holding device of the second embodiment consists of a clamping wedge member 2, a clamping member 6 clamping the sling 1, an elastic body 10, a winding wedge member 3 on which the sling 1 is wound, and The sleeve 5 is constituted in which the clamping wedge member 2 is divided into a plurality of parts and provided to clamp the sling 1, and the elastic body 10 is inserted between the clamping wedge member 2 and the clamping member 6 , the clamping wedge member 2 , the clamping member 6 , the elastic body 10 and the winding wedge member 3 are arranged inside the sleeve 5 . In addition, a pin 8 is installed on the upper part of the sleeve 5, and a collar rod 9 is fixed on the pin 8, as Image 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com