Quick wax spray rubber composition and preparation method thereof

A rubber composition and rapid technology, which is applied in the field of rapid wax spray rubber composition and its preparation, can solve the problems of paraffin not being able to flow freely, difficulty in spraying out paraffin, spraying out, etc., to achieve good protection against ozone aging and reduce friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

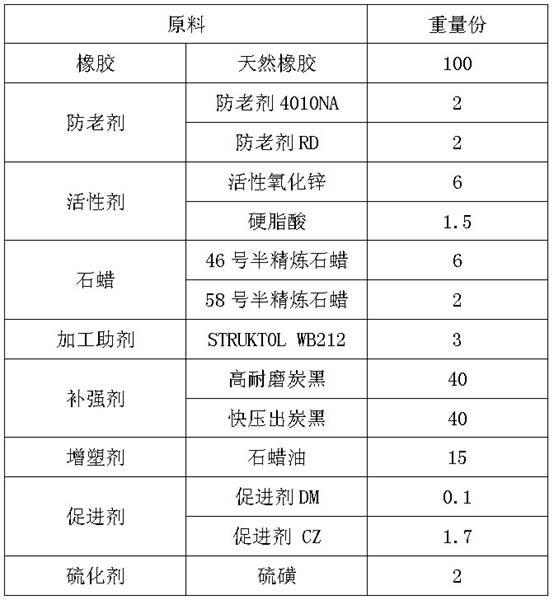

[0020] The invention provides a kind of quick wax spray rubber composition, is made up of following components in parts by weight:

[0021]

[0022] Its processing technology is as follows:

[0023] Step 1, one stage of rubber mixing:

[0024] Step 1.1, kneading the above-mentioned rubber by weight in an internal mixer for 20 seconds to soften, and controlling the temperature of the internal mixing chamber at 60°C;

[0025] Step 1.2, adding the active agent, anti-aging agent, processing aid and paraffin wax in the above parts by weight and kneading in the internal mixer, the kneading time is 4min;

[0026] Step 1.3. Pour the reinforcing agent and plasticizer in the above parts by weight into the internal mixer and continue kneading. After 5 minutes of kneading, transfer to the open mixer for thin pass 3 times, and then thicken it. Cutting knife 2 times each;

[0027] Step 2. Parking: put the mixed rubber completed through the above steps into a constant temperature room...

Embodiment 2

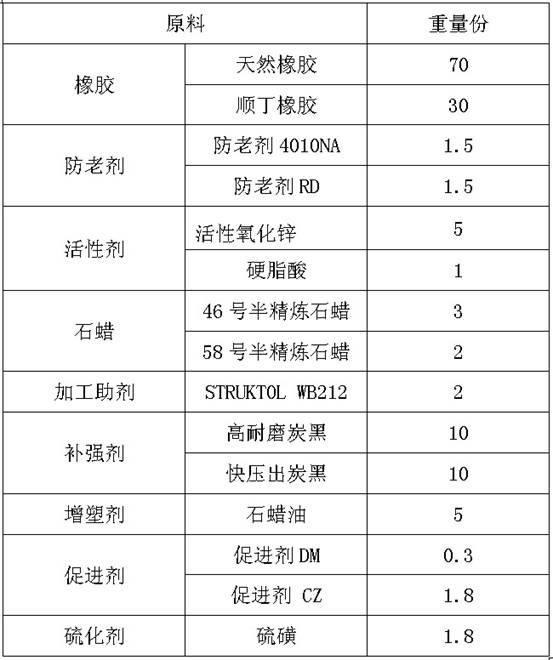

[0033] The invention provides a kind of quick wax spray rubber composition, is made up of following components in parts by weight:

[0034]

[0035] Its processing technology is as follows:

[0036] Step 1, one stage of rubber mixing:

[0037] Step 1.1, kneading the above-mentioned parts by weight of the plasticized rubber in an internal mixer for 40 seconds to soften, and controlling the temperature of the internal mixing chamber at 100°C;

[0038] Step 1.2, adding the active agent, anti-aging agent, processing aid and paraffin wax in the above parts by weight and kneading in the internal mixer, the kneading time is 6min;

[0039] Step 1.3. Pour the reinforcing agent and plasticizer in the above weight parts into the internal mixer and continue kneading. After the kneading time is 8 minutes, transfer it to the open mixer for thin pass 3 times, and then thicken it. Cutting knife 2 times each;

[0040] Step 2. Parking: put the mixed rubber completed through the above step...

Embodiment 3

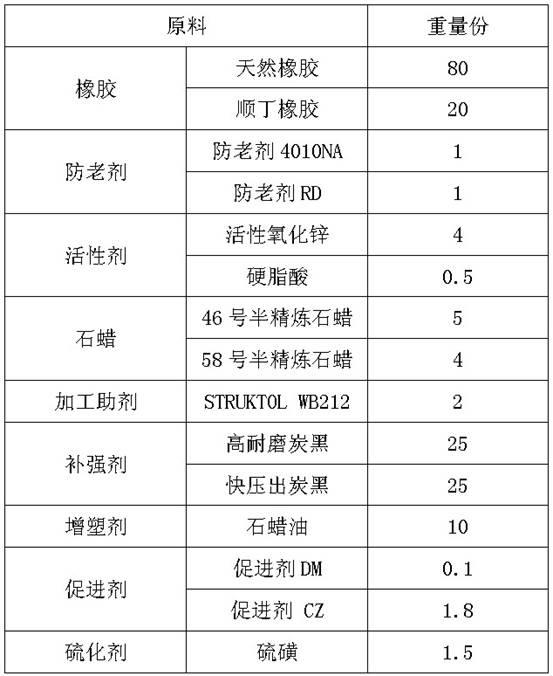

[0045] A kind of rubber composition of automobile chassis with self-lubricating stabilizer bushing products, containing the following components in parts by weight:

[0046]

[0047] Its processing technology is as follows:

[0048] Step 1, one stage of rubber mixing:

[0049] Step 1.1, kneading the above-mentioned parts by weight of the plasticized rubber in an internal mixer for 30 seconds to soften, and controlling the temperature of the internal mixing chamber at 100°C;

[0050] Step 1.2, adding the active agent, anti-aging agent, processing aid and paraffin wax in the above parts by weight and kneading in the internal mixer, the kneading time is 6min;

[0051] Step 1.3. Pour the reinforcing agent and plasticizer in the above weight parts into the internal mixer and continue kneading. After the kneading time is 8 minutes, transfer it to the open mixer for thin pass 3 times, and then thicken it. Cutting knife 2 times each;

[0052] Step 2. Parking: put the mixed rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com