Combined steel column and manufacturing method thereof

A manufacturing method and technology of steel columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems that the roof truss support cannot be realized, and achieve the effect of expanding the design scale, simple and ingenious design, and suitable for factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with specific embodiments, the present invention will be further illustrated, and it should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. The modifications are all within the scope of the appended claims of this application.

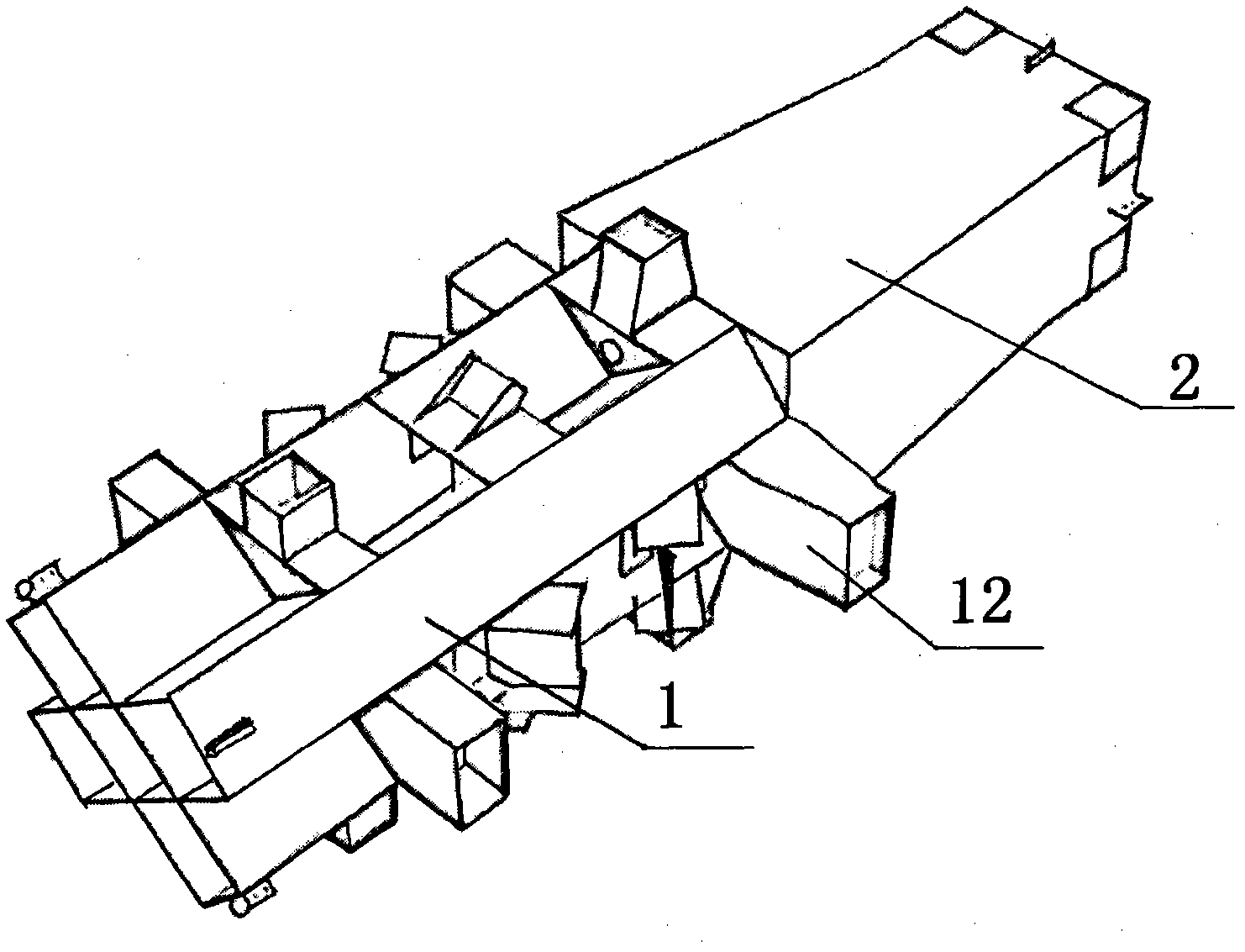

[0060] like figure 1 A composite steel column shown, including an upper section column 1 and a lower section column 2;

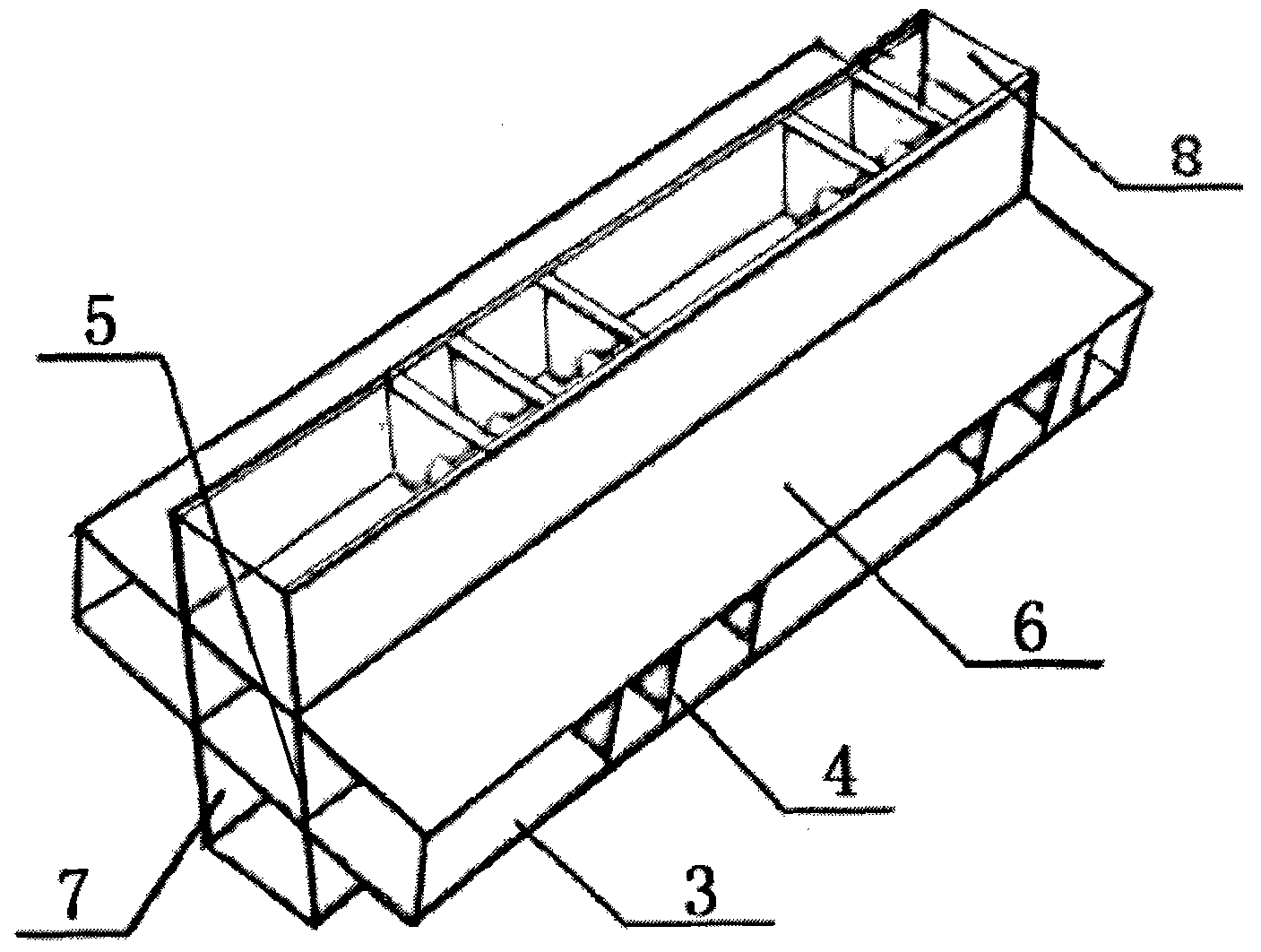

[0061] The upper section column 1 includes: bottom plate 3, inner partition plate 4, web plate 5, face plate 6, side plate 7, inlay plate 8 and corbel 12;

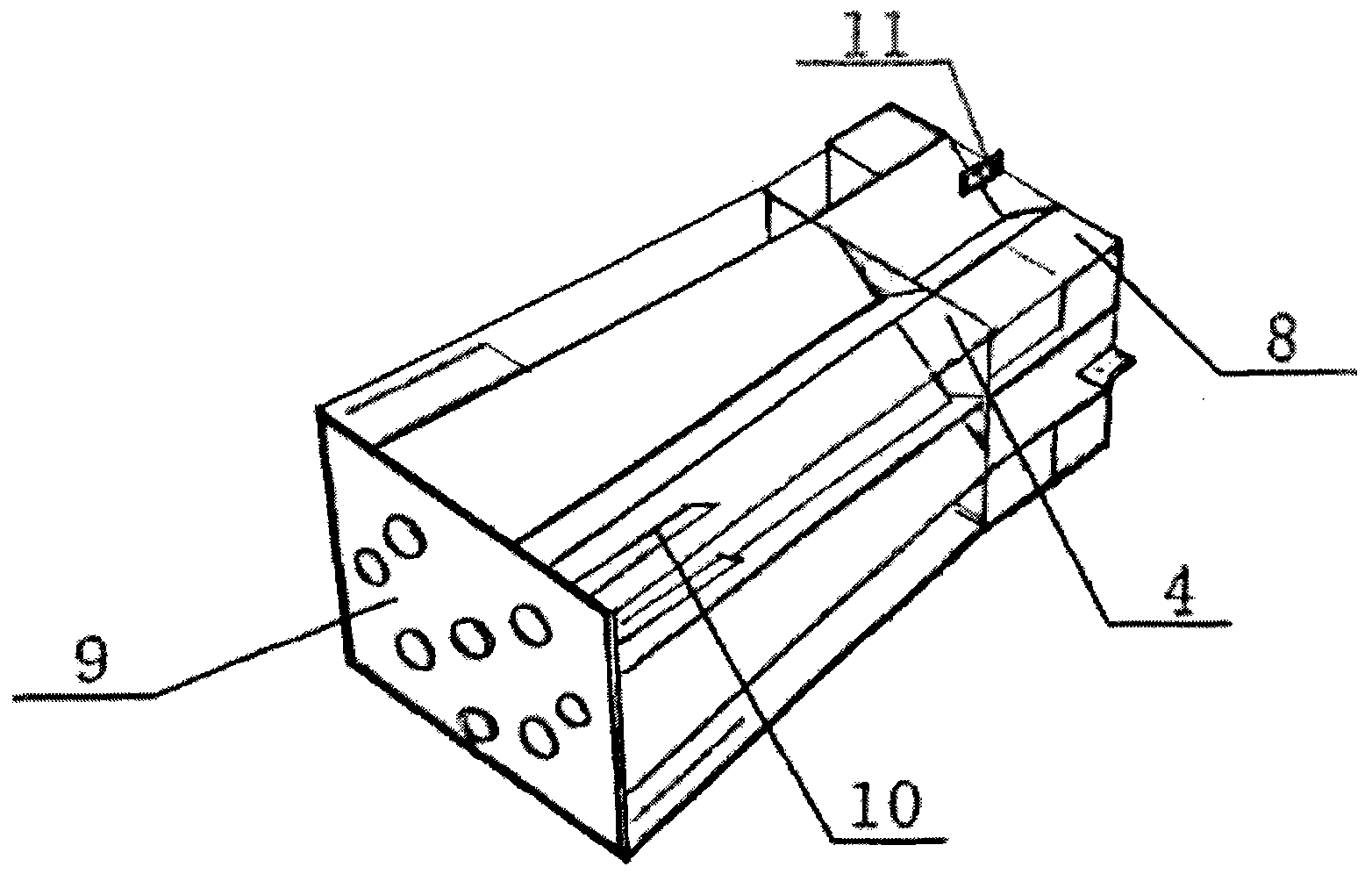

[0062] The lower column 2 includes: bottom plate 3, inner partition plate 4, web plate 5, face plate 6, side plate 7, inlay plate 8, transition connecting plate 9, stiffening plate 10 and ear plate 11;

[0063] The production steps of the upper section column 1 are as follows:

[0064] (1) First, according to the actual projected size of the upper column box,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap