Aligning roller bearing comprising improved notches for mounting rollers

A self-aligning roller bearing and a technology for installing rollers, which is applied to rolling contact bearings, bearing components, shafts and bearings, etc., can solve the problems of high noise, raceway damage, and low life, so as to reduce labor intensity and avoid The effect of bruising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

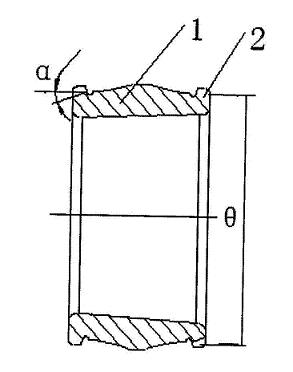

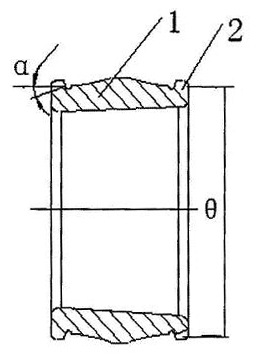

[0010] Such as figure 1 As shown, the present invention improves the self-aligning roller bearing with roller notches, including outer ring, inner ring 1, rollers and cages. There are notches on the ribs 2 on both sides of the inner ring 1, and the two notches are separated by an angle θ The gap is 175°, the angle α between the gap and the outer diameter of the rib 2 is 5°, and the processed gap is like a "tooth pear" shape. In the previous process, there is a gap on each end face, a straight gap, and the gaps on both sides are staggered by 180°, which is changed to The last notch has an angle of 4-5°, and the notches on both ends of each row of rollers are designed to be staggered by half the angle of the rollers, that is, the notches on both sides are staggered by 175°; each row of rollers is notched on both ends of an odd number It is designed to be staggered by 180°, the notch and the outer diameter of the rib form an angle of 5°, and the processed notch is like a "tooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com