Bearing blockseat of slag breaking machine

A technology of bearing seat and slag breaker, which is applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems that the bearing is easy to be damaged and affects the normal use of the slag breaker, so as to achieve not easy damage, ensure normal use, and work environment The effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

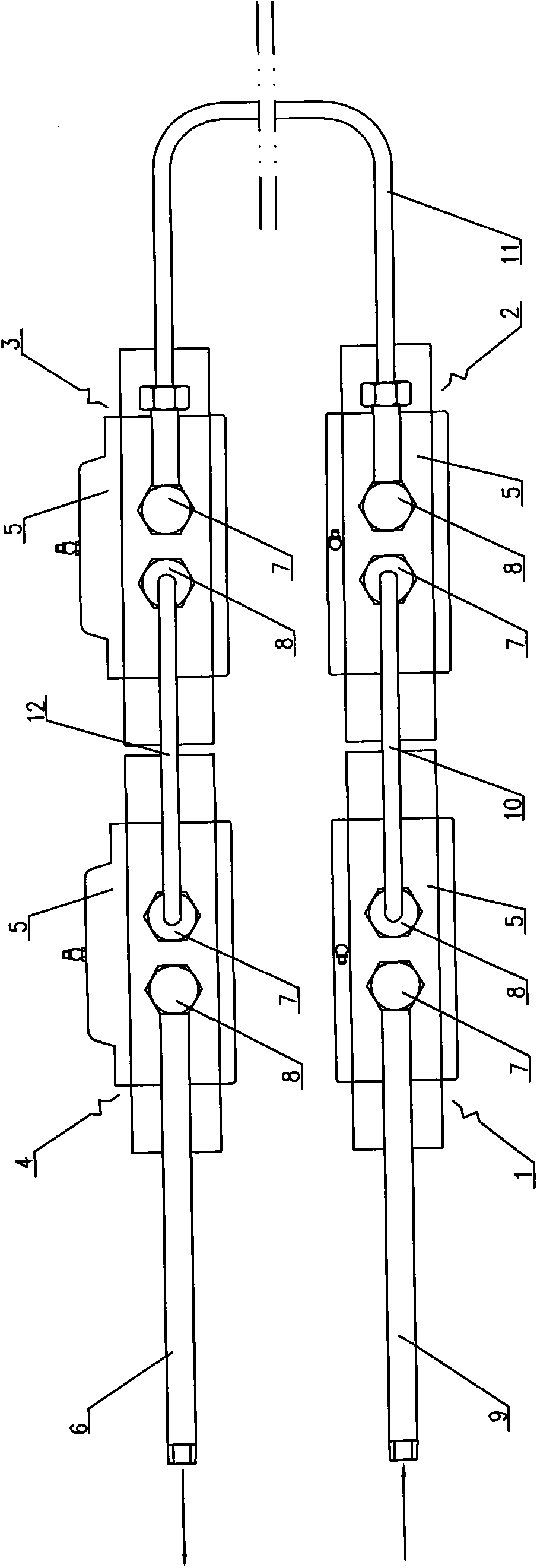

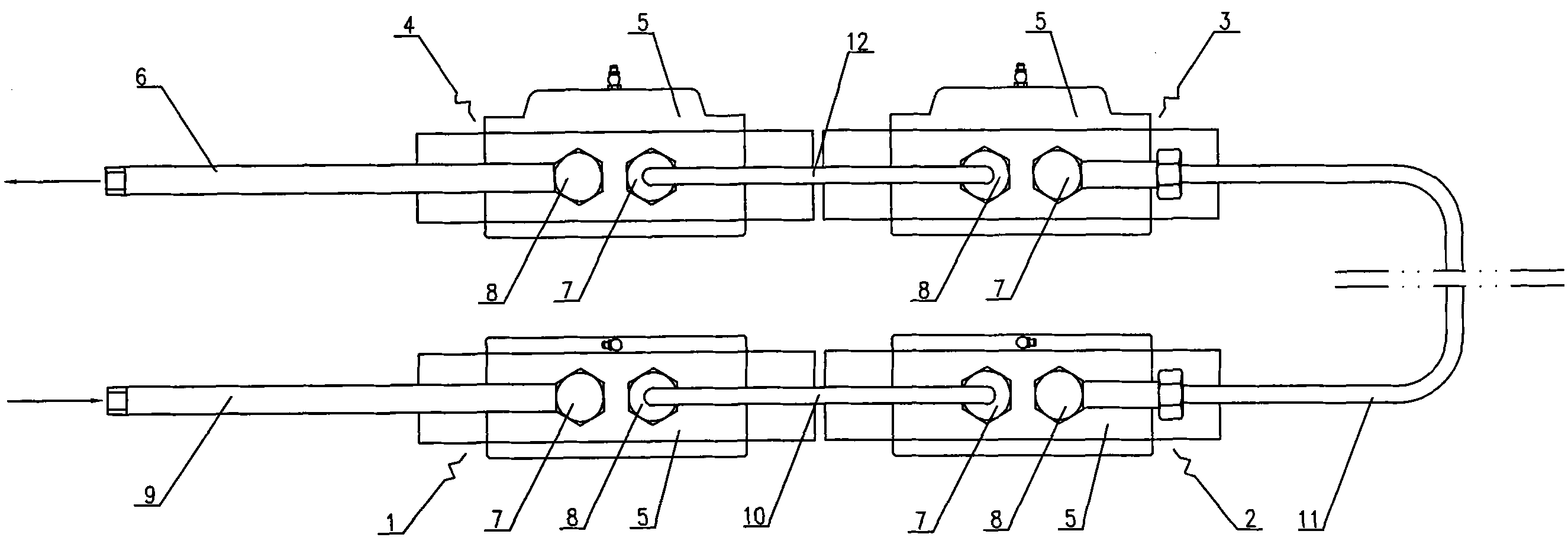

[0007] See figure 1 , which includes four bearings, the four bearings correspond to four bearing seats 1, 2, 3, 4, and the housing of each bearing seat includes an outer shell 5 and an inner shell (not shown in the figure, this structure is an existing mature technology ), the cooling cavity between the inner shell and the outer shell (not shown in the figure, this structure is an existing mature technology), the inlet 7 and the outlet 8 of each cooling cavity are respectively arranged on the outer shell 5 of the outer shell bearing seat, the first The inlet 7 of the cooling cavity of a bearing seat (bearing seat 1 in the figure) is connected to the medium input pipe 9, and the outlet 8 of the cooling cavity of the last bearing seat (bearing seat 4 in the figure) is connected to the output pipe 6, and the adjacent The cooling cavity of the bearing seat is connected in series, so that the coolant is connected to the inlet 7 of the bearing seat 1 through the medium input pipe 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com