Highly-efficient light emitting diode (LED) power supply

A technology of LED power supply and LED light source, applied in electric light source, light source, electric lamp circuit layout and other directions, can solve the problems of high power supply cost, increase hidden trouble of failure, and high cost, increase LED temperature compensation function, reduce production cost and failure rate , The effect of reducing the temperature of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

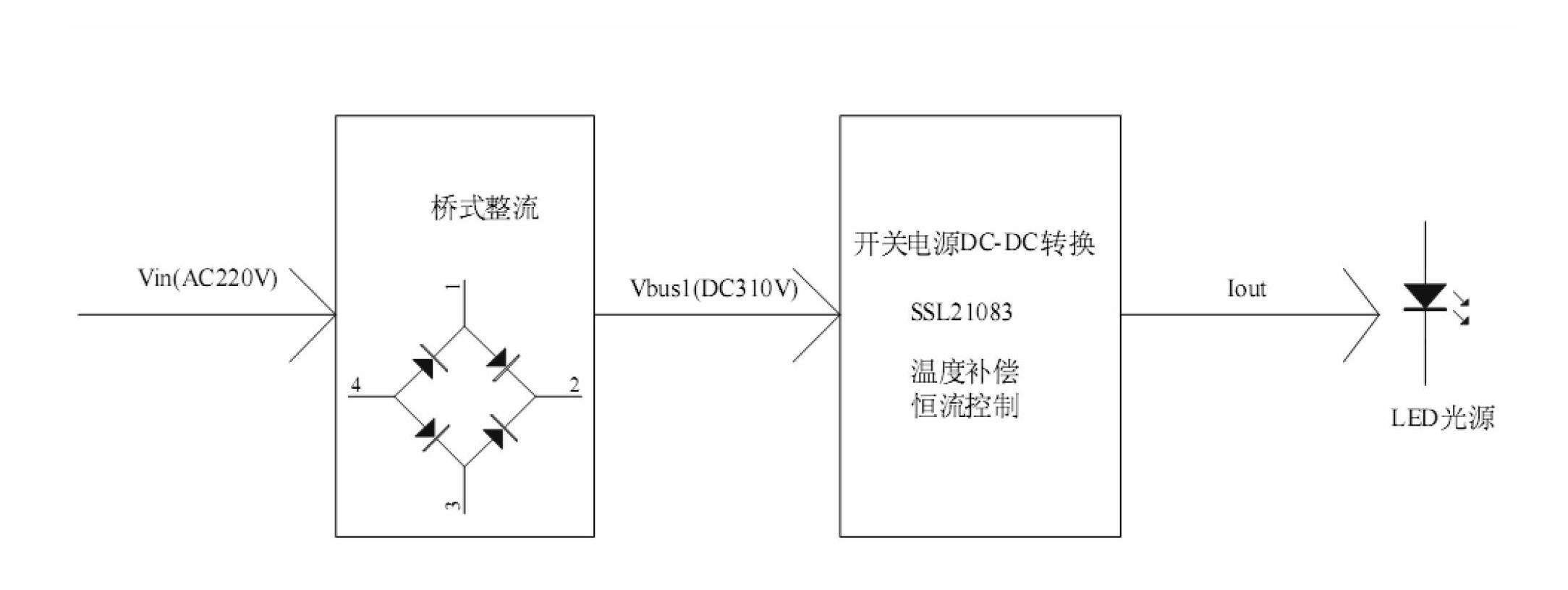

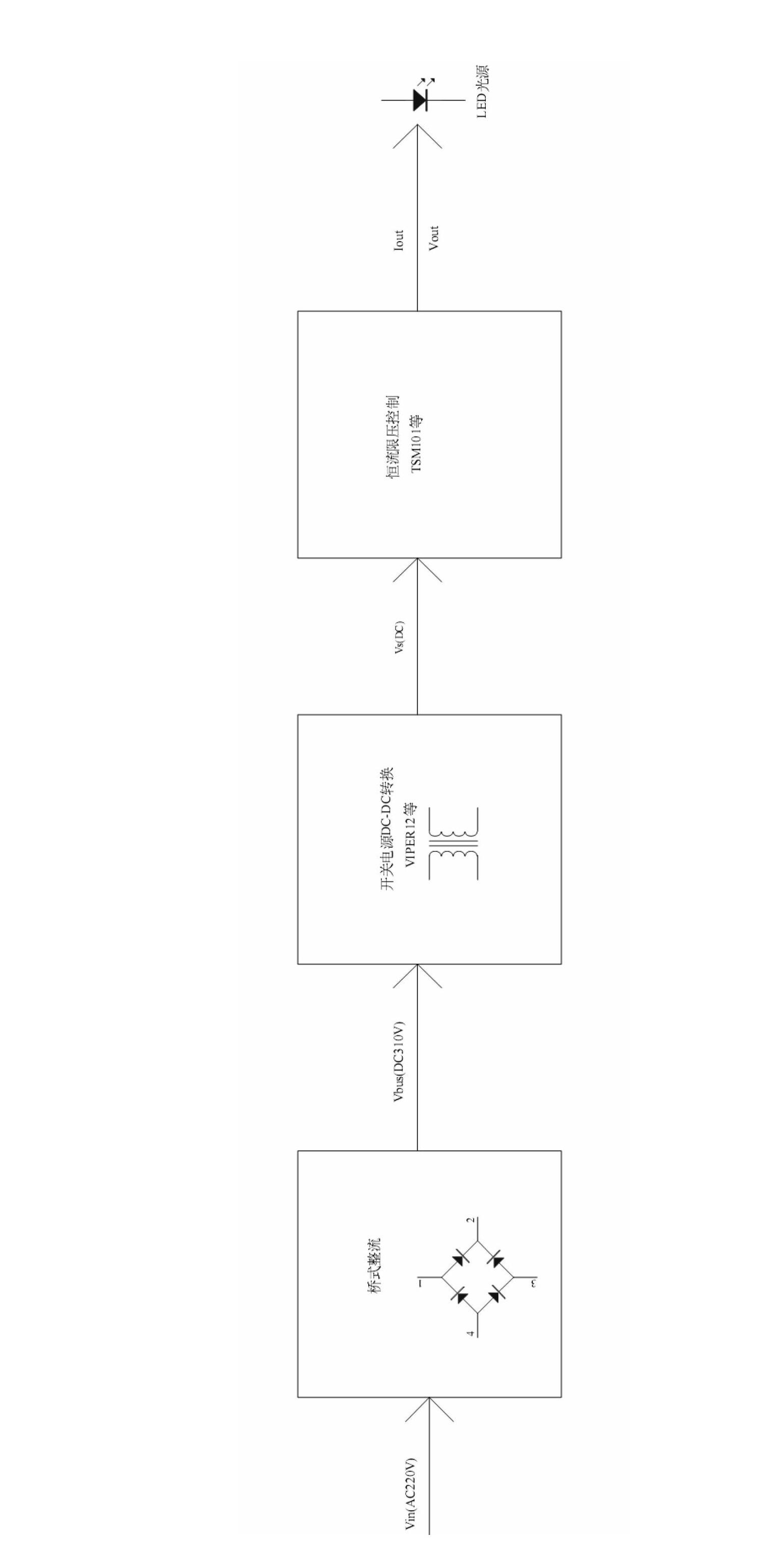

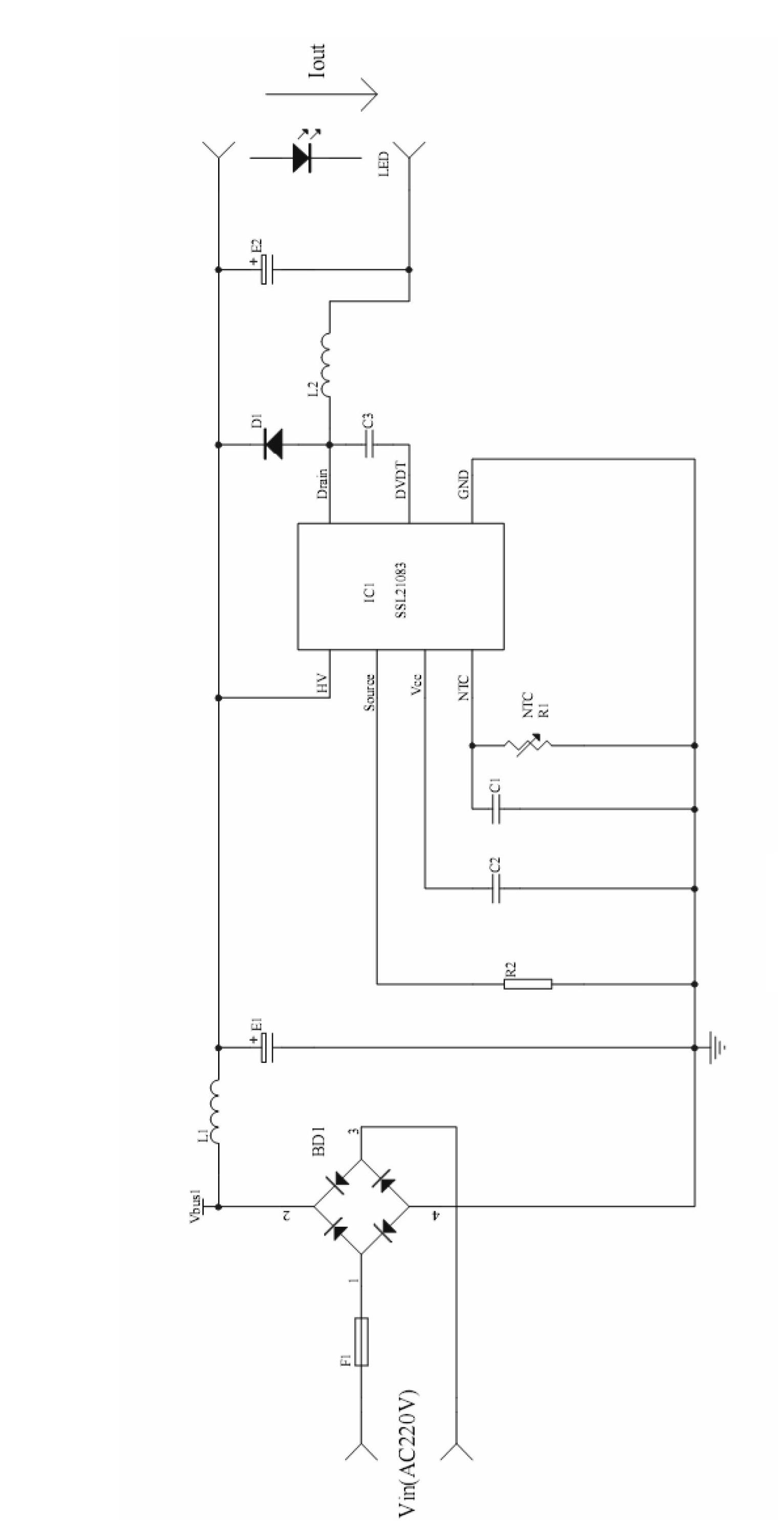

[0021] The present invention will be further described below in conjunction with drawings and embodiments. The present invention is used for LED lighting with AC 220V input and constant current output, including a bridge rectifier module and a switching power supply DC-DC conversion module. The output end of the bridge rectification module is connected to the LED light source through the switching power supply DC-DC conversion module, such as figure 2 shown. Specific circuit such as image 3 shown, including:

[0022] 1. Bridge rectifier module. Used to convert AC input into DC voltage Vbus1.

[0023] 2. Switching power supply conversion chip SSL21083 and peripheral circuits.

[0024] Such as image 3 , The power supply is a step-down BUCK circuit.

[0025] The rectifier bridge BD1 of the bridge rectifier module converts the AC input into a DC voltage Vbus1, and the waveform of Vbus1 is in the form of a half sine wave. The positive pole of the rectifier bridge BD1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com