Self-sealing transfusion valve component and plug valve and socket valve thereof

A self-sealing, infusion valve technology, applied in the direction of valve devices, functional valve types, engine components, etc., can solve the problems of low liquid temperature, no liquid filling work, inconvenient application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

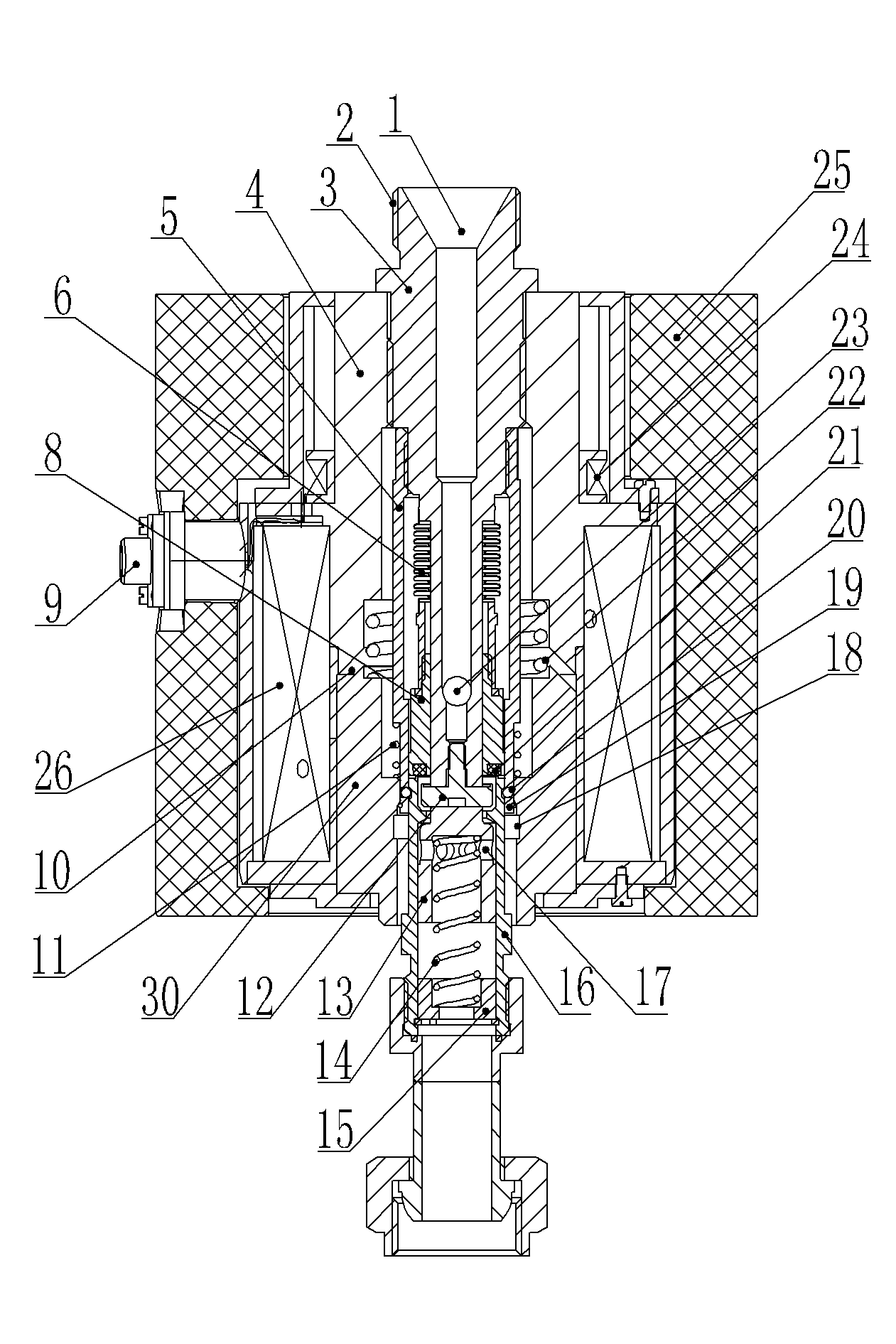

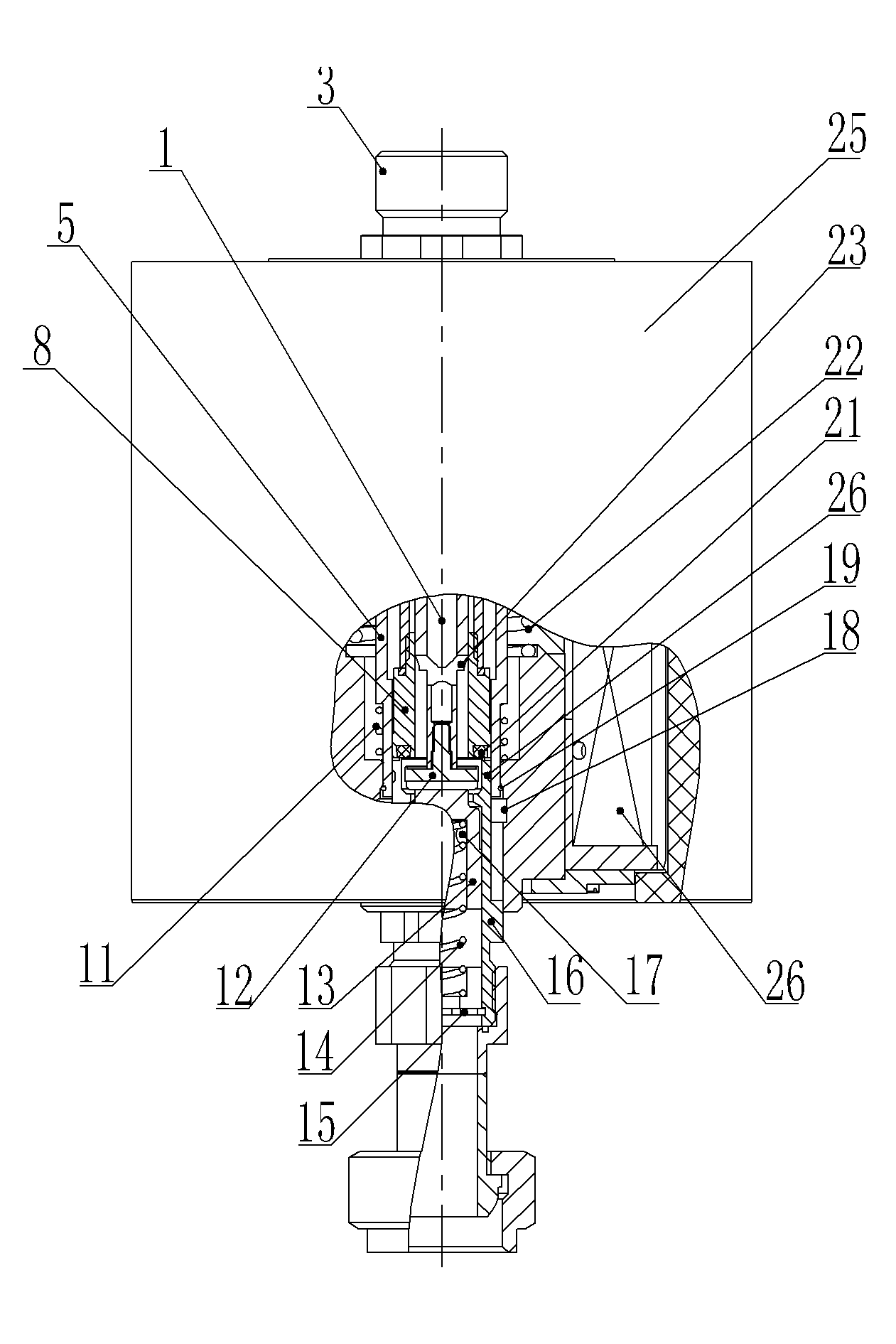

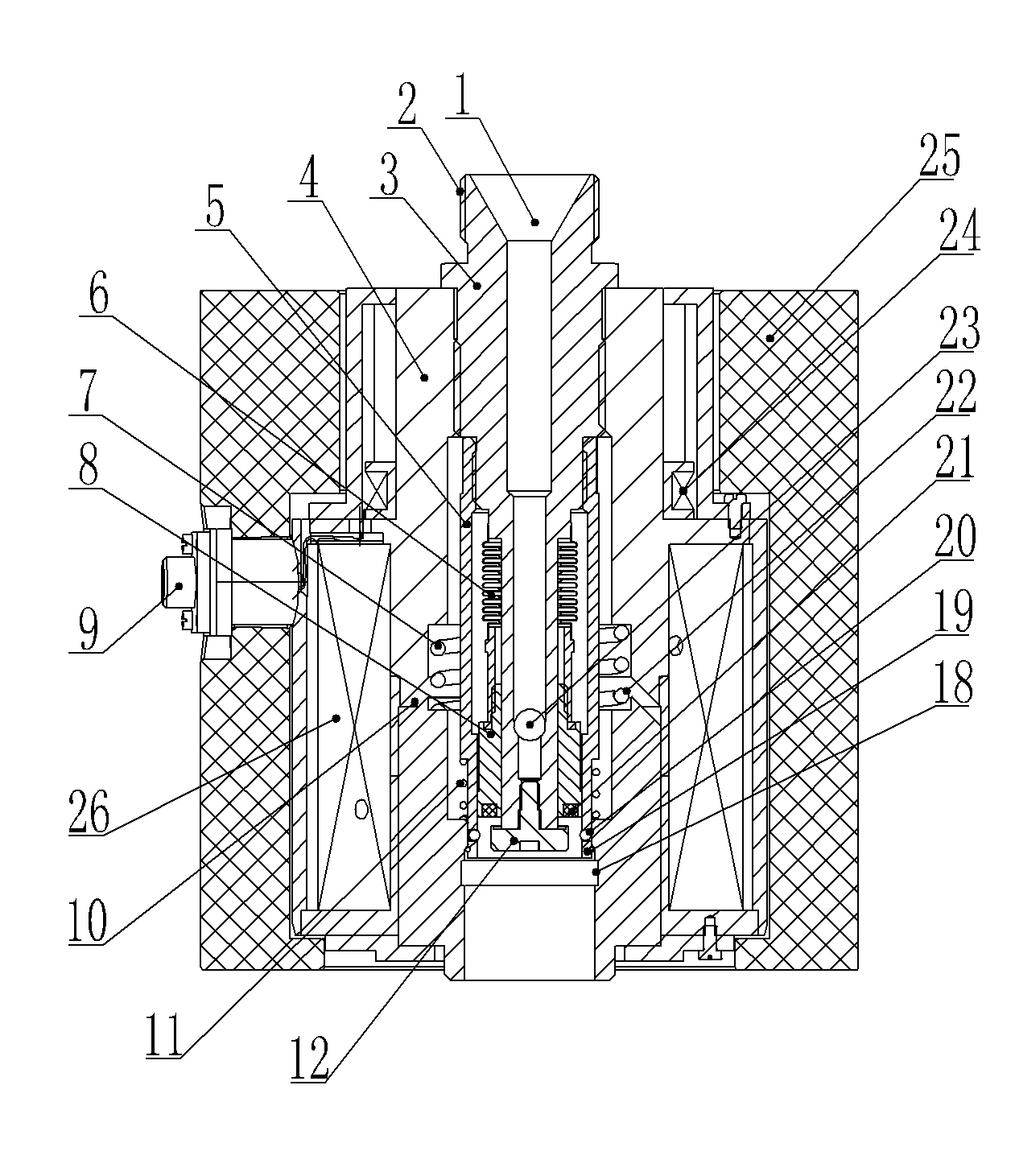

[0022] An embodiment of a self-sealing infusion valve assembly, in figure 1 , 2 in, combine image 3 and Figure 4, the infusion valve assembly includes a socket valve and a plug valve. Hole 1, the front end of the through hole 1 has an internal thread, and a sealing disc 12 is screwed through the thread, the sealing disc 12 seals the front end of the through hole 1, and the front part of the through hole 1 has a wall extending from the wall of the through hole 1 to the socket valve The radial hole 23 on the outer wall of the part 3, the socket valve part 3 is a circular tube, and its front end has two parallel planes extending backward from the front end to the rear of the radial hole 23. The front part of the socket valve part 3 is slidingly sleeved with a self-sealing tube 8, and the rear end of the self-sealing tube 8 is in sealing cooperation with the part after the radial hole 23 of the socket valve part 3. Since the front section of the socket valve part 3 has a cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com