Electric appliance fault detection method, device and system

A technology for fault detection and electrical appliances, which is applied to measuring devices, instruments, measuring electricity, etc., can solve the problems of difficult to locate faults, time-consuming and labor-intensive efficiency, and achieve the effect of simplifying the structure and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

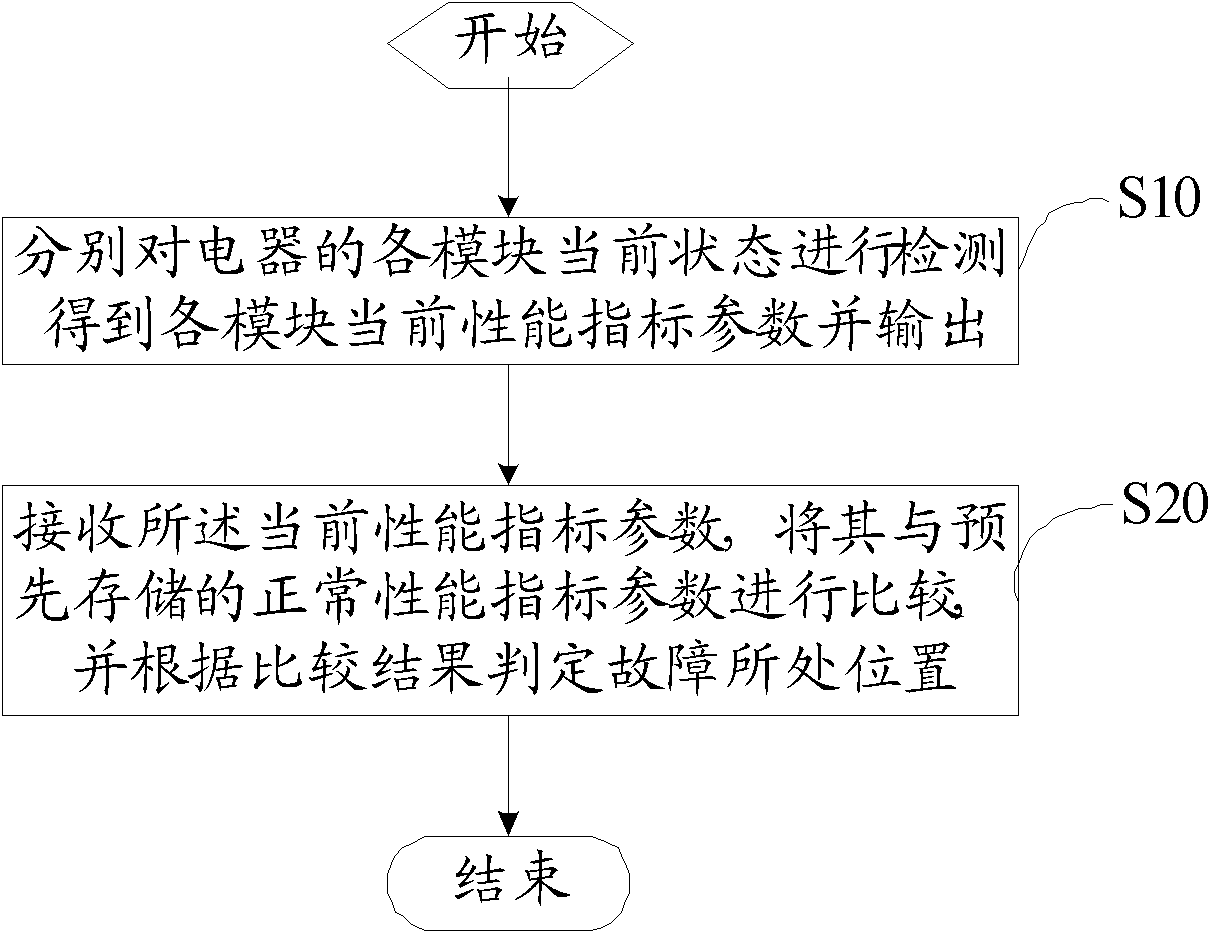

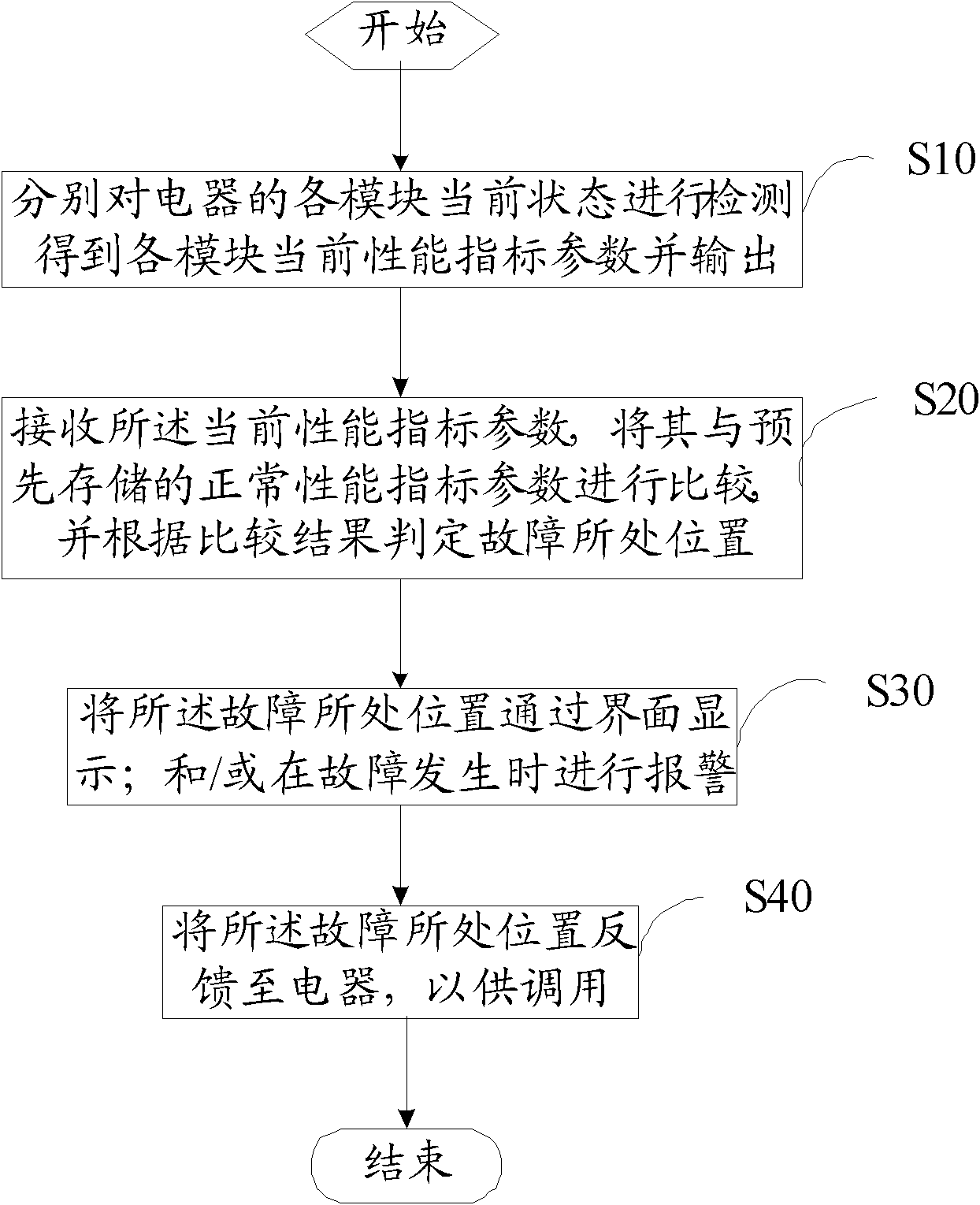

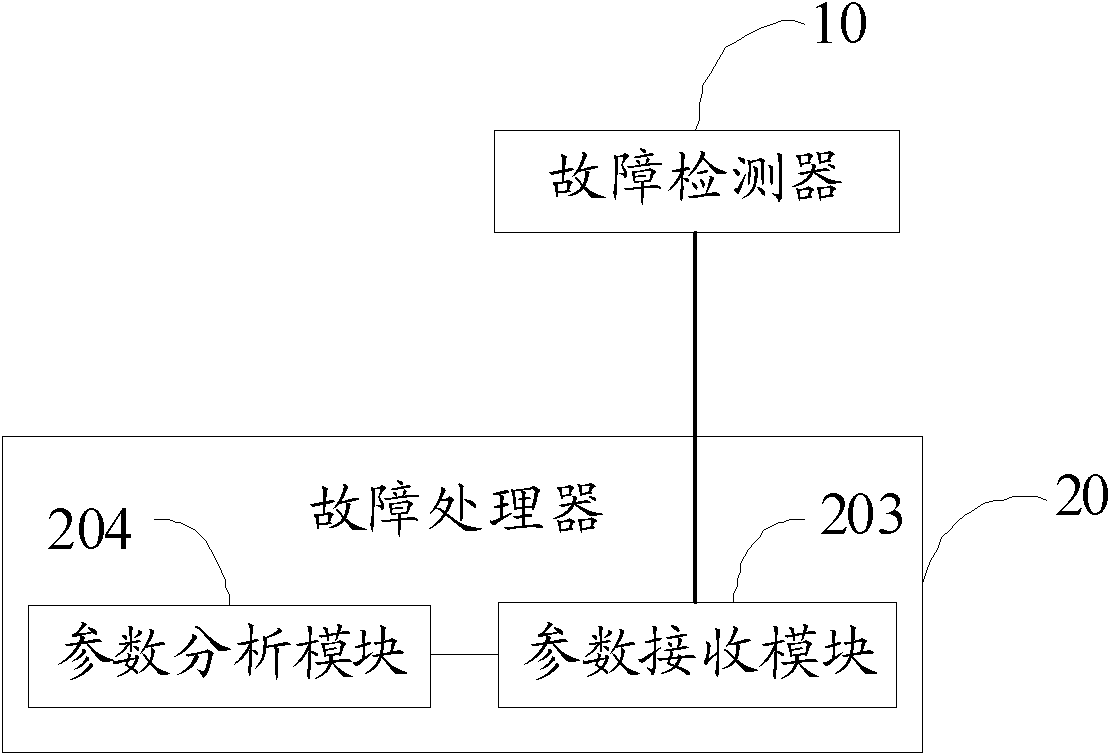

[0041] refer to figure 1 , propose an embodiment of a method for detecting electrical faults of the present invention, comprising the following steps:

[0042] Step 10: Detect the current state of each module of the electrical appliance to obtain the current performance index parameters of each module and output it; The current performance index parameters corresponding to the module. The performance index parameters of each unit and module can be extracted through the test of the module or directly. The performance index parameters include the corresponding parameters such as current, voltage, temperature, etc. The performance index parameters that need to be detected by different electrical appliances are different. In the above embodiment, the detection of electrical appliances can be performed periodically and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com