Method and device for performing multi-section characteristic processing and generating four-axis codes

A multi-section, code technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of limiting the processing range of parts, taking a long time to process codes, unable to meet the needs of production, etc., to reduce the difficulty and risk of operation, reduce The effect of processing preparation time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

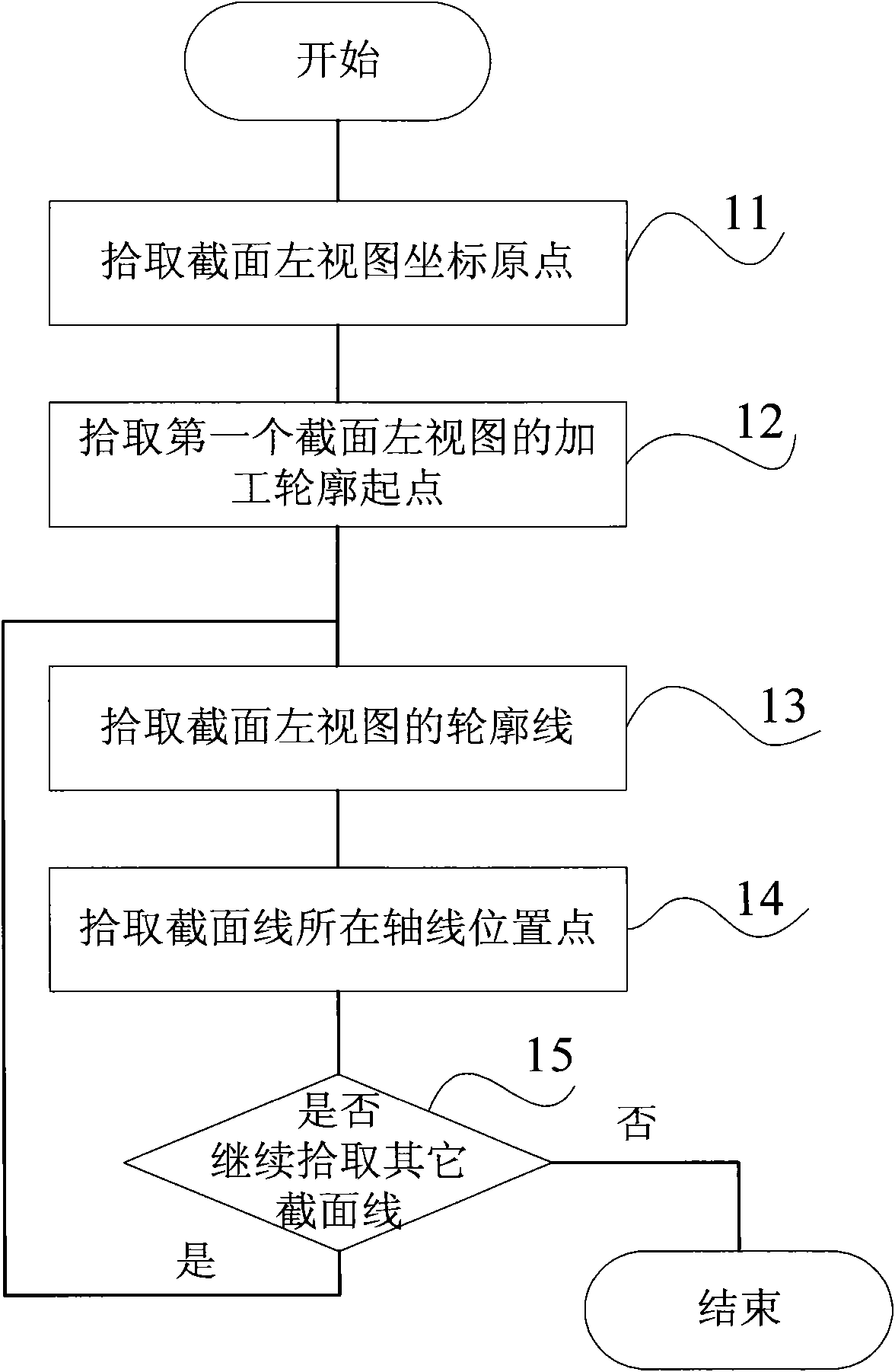

[0055] The invention combines the technological characteristics of the four-axis numerical control lathe, designs and develops a method and a device for multi-section feature processing and four-axis code generation. The so-called multi-section can also be called variable section, which means that the cross-sectional shape of the part at different axis positions is different. The section can be composed of multiple line segments, such as a hexagon, or it can be composed of a curve, such as an ellipse. After the trajectory is generated, the four-axis code is generated through the post-processing of the four-axis CNC car, and this code is input into the four-axis CNC car to realize the processing of multi-section feature parts. The device provides a graphical full Chinese interface display and is easy to operate.

[0056] The method for processing multi-section features and generating four-axis codes according to the present invention includes the following steps:

[0057] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com