Turbine and method for cleaning turbine blades under operation conditions

A technology of turbine blades and operating conditions, applied to engine components, gas turbine devices, machines/engines, etc., can solve problems such as reduced revenue, reduced cleaning times, engine and turbocharger damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

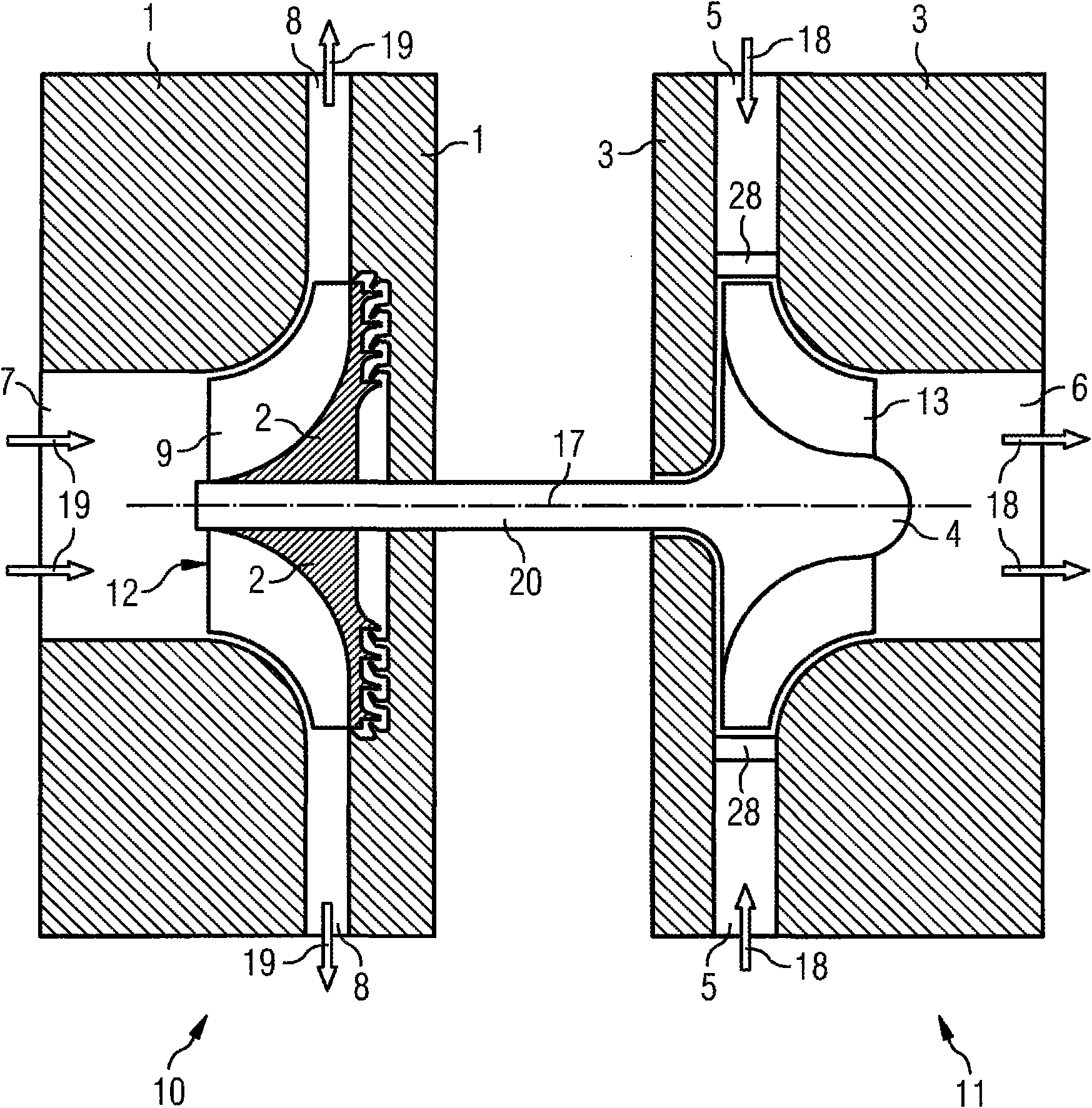

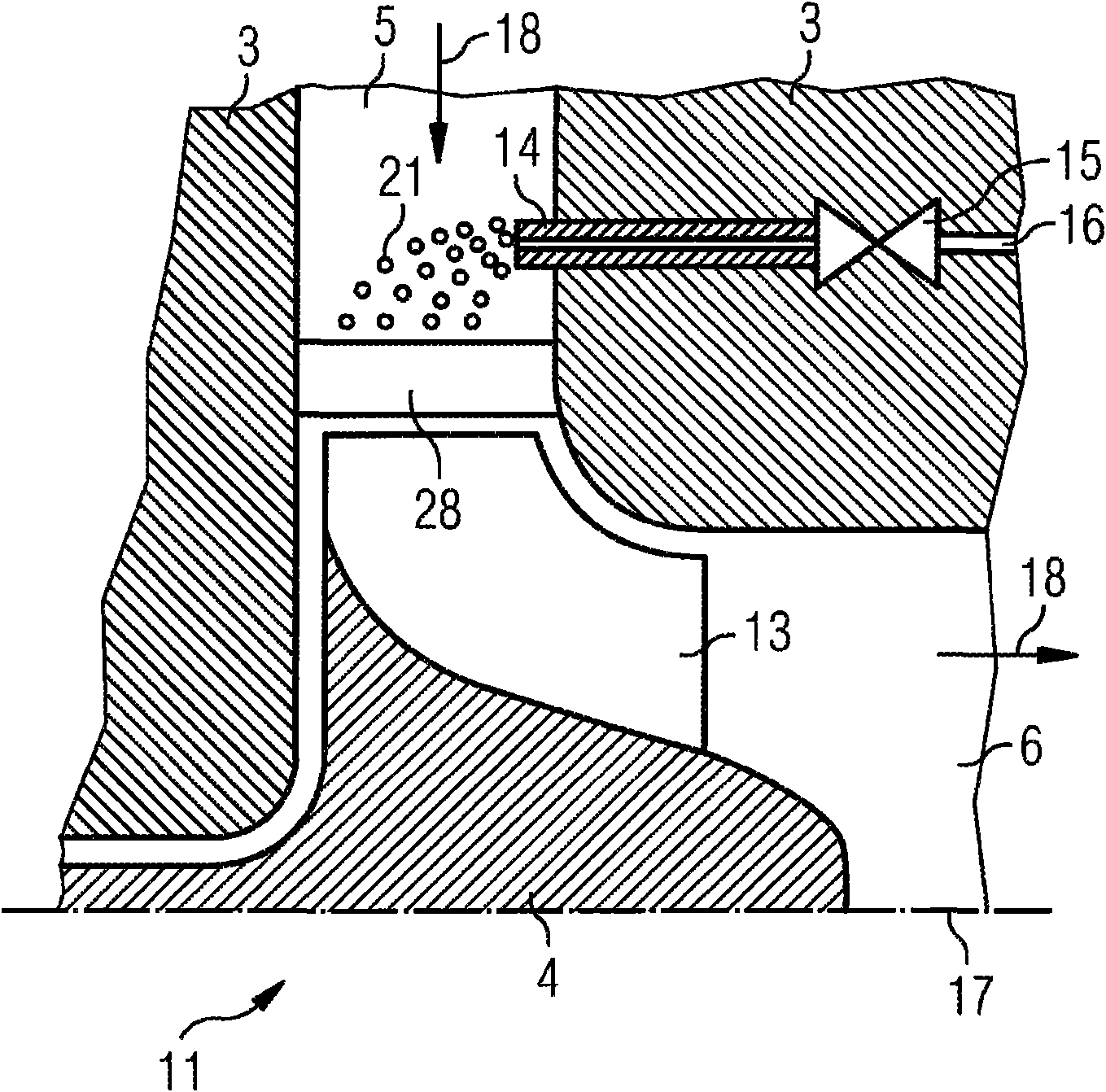

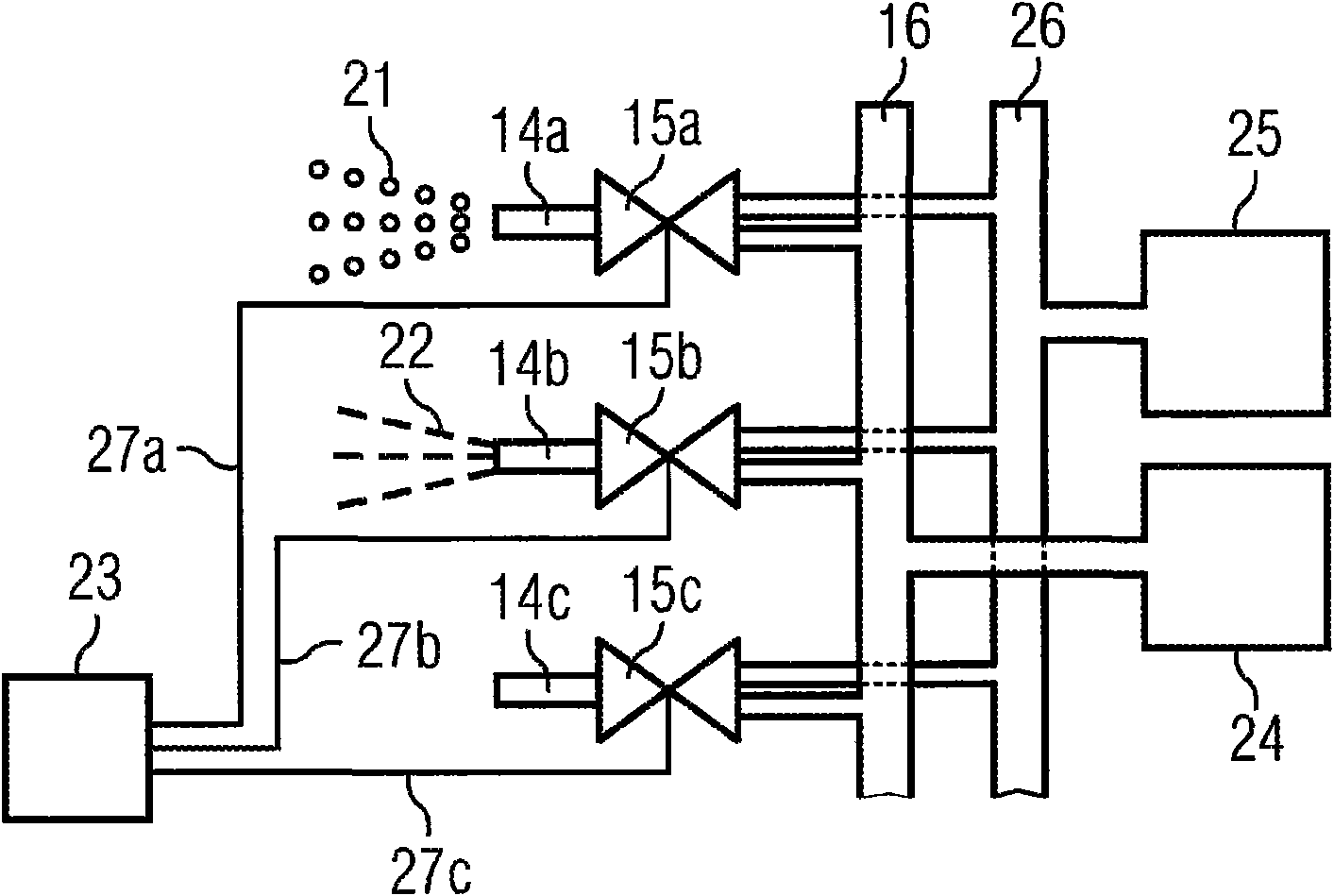

[0032] will now refer to Figure 1-3 Embodiments of the present invention will be described.

[0033] figure 1 A cross-sectional view of a turbocharger is schematically shown. The turbocharger includes a turbine 11 and a compressor 10 . The turbine 11 and the compressor 10 are connected by a shaft 20 .

[0034] The turbine 11 comprises a rotor 4 placed inside a turbine casing 3 . The turbine casing 3 has an exhaust gas inlet 5 to the rotor 4 such that exhaust gas entering the exhaust gas inlet 5 actuates the rotor 4 . Furthermore, the turbine housing 3 has an exhaust outlet 6 via which the exhaust gas from the rotor 4 leaves the turbine housing 3 . Arrow 18 indicates that the exhaust gas flow enters the turbine casing 3 through the exhaust inlet 5 , actuates the rotor 4 and then leaves the turbine casing 3 through the exhaust outlet 6 .

[0035] The compressor 10 includes an impeller 12 placed inside the compressor casing 1 . Furthermore, the compressor 10 has an air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com