Squeezing machine

A squeezer and machine body technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of hand injury, high labor intensity, unreasonable structure, etc., and achieve the effect of improving safety factor, avoiding accidental injury, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

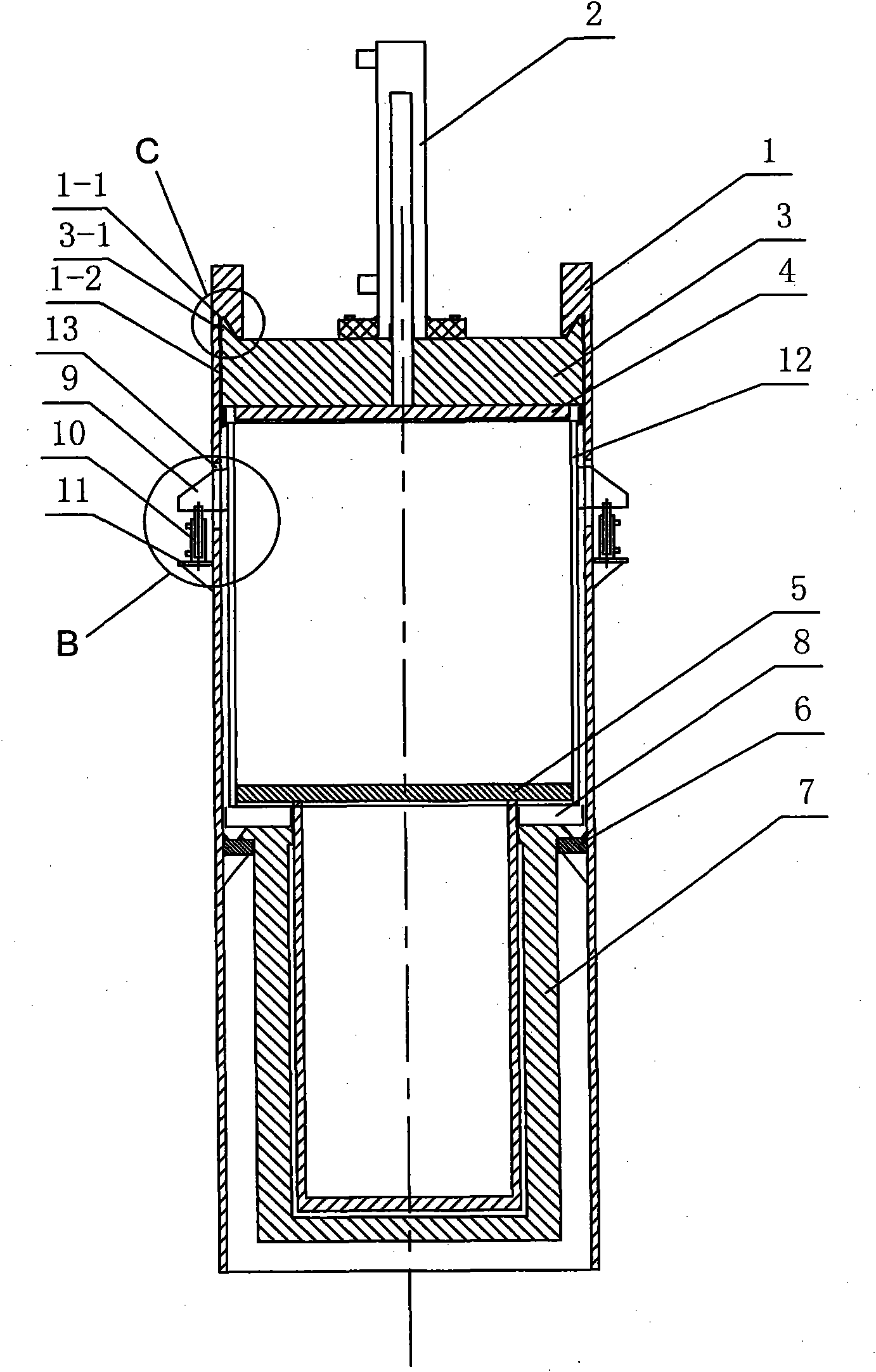

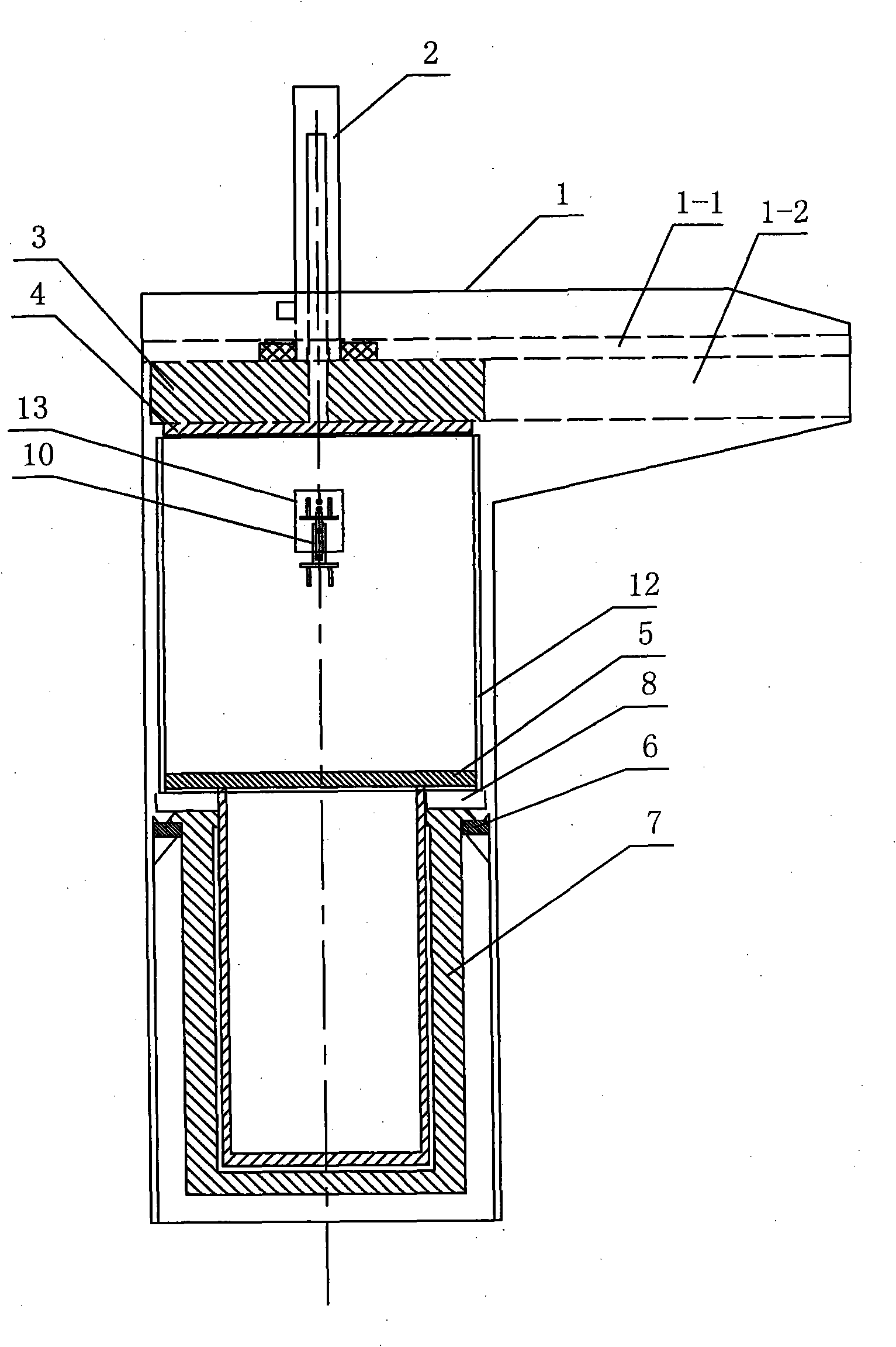

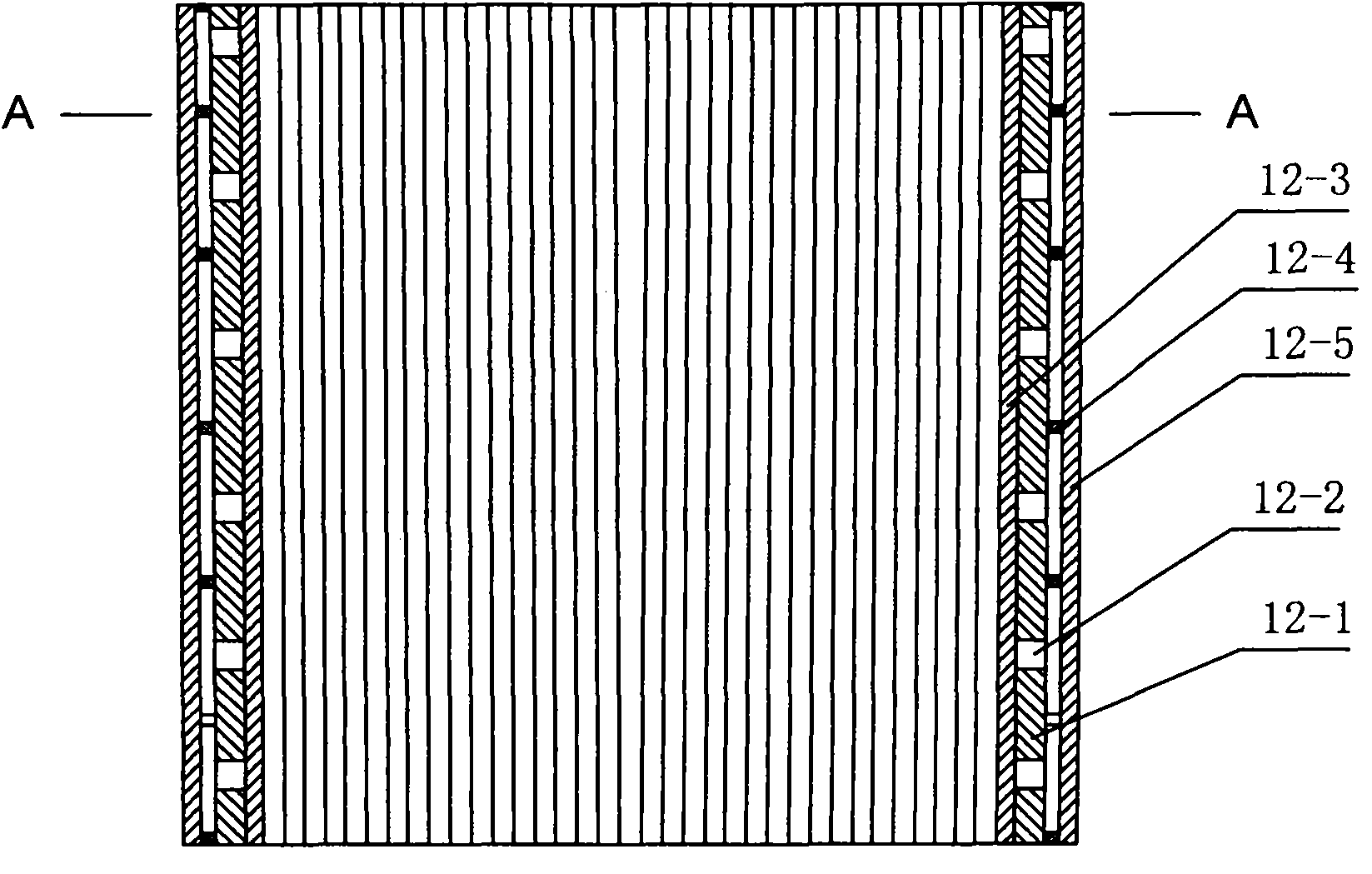

[0016] Such as figure 1 , 2 , shown in 5 and 6, is a kind of squeezing machine, comprises body 1, and radial groove 1-2 is arranged respectively on the left and right sides of the inner top of body 1, and a vertical through hole 13 is respectively arranged on the left and right sides of body 1, The body 1 is provided with a first oil cylinder 7 , a pressing die 12 and a top plate 3 .

[0017] The first oil cylinder 7 is fixed in the machine body 1 through the support plate 6 , the pressing die 12 is arranged above the first oil cylinder 7 , and the top plate 3 is arranged above the pressing die 12 . The left and right sides of the top plate 3 are respectively arranged in the radial grooves 1-2. The top of each radial groove 1-2 is respectively provided with a V-shaped groove 1-1, and the left and right sides of the top of the top plate 3 are respectively provided with protrusions 3-1 matching the V-shaped groove 1-1. The telescopic end of the first oil cylinder 7 is fixedly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap