Constant-strength high-convex-ladder-shaped coal mine underground deep supporting device

A support device and a technology of convex ladders, which are applied in the field of deep support devices in strong and high convex ladder-type coal mines, can solve the problems of the special elasticity of the steel belt convex structure, the reduction of the buffer bearing capacity against the roof, and the cracks or cracks in the support section. To improve the support strength, reduce the vertical pressure and improve the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

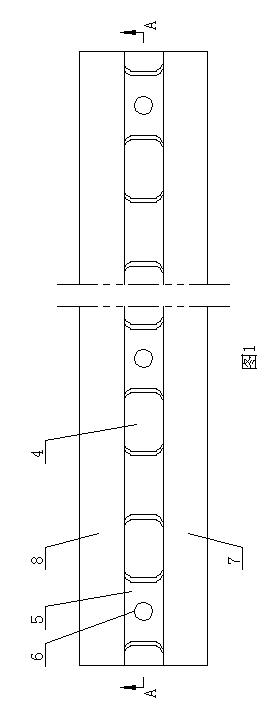

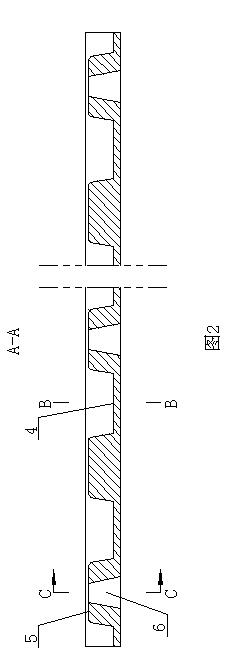

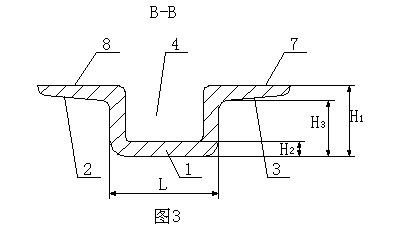

[0008] figure 1 Shown is a schematic view of the structure of the supporting device of the present invention, comprising a strip-shaped main steel strip, the middle part of the strip-shaped main steel strip is provided with a boss 1, the boss 1 runs through the entire length of the strip-shaped main steel strip, and the boss 1. The two bottom ends are respectively connected with the highest points of the first slope 3 and the second slope 2. At least two elongated grooves 4 are provided in the length direction of the back of the boss 1. The two opening ends of the elongated groove 4 are respectively Connected with the inner ends of the first plane 7 and the second plane 8, the outer end of the first plane 7 intersects with the outer edge of the first slope 3 extending outward gradually, and the outer end of the second plane 8 and the second slope 2 gradually The outer edges o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com