Electronic defrosting system having refrigerating chamber stopping function

A refrigerator, electronic technology, used in defrosting, household refrigeration devices, household appliances, etc., can solve the problems of long design and development cycle, low control accuracy, poor reliability, etc., to enhance work reliability and avoid excessive temperature. low, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

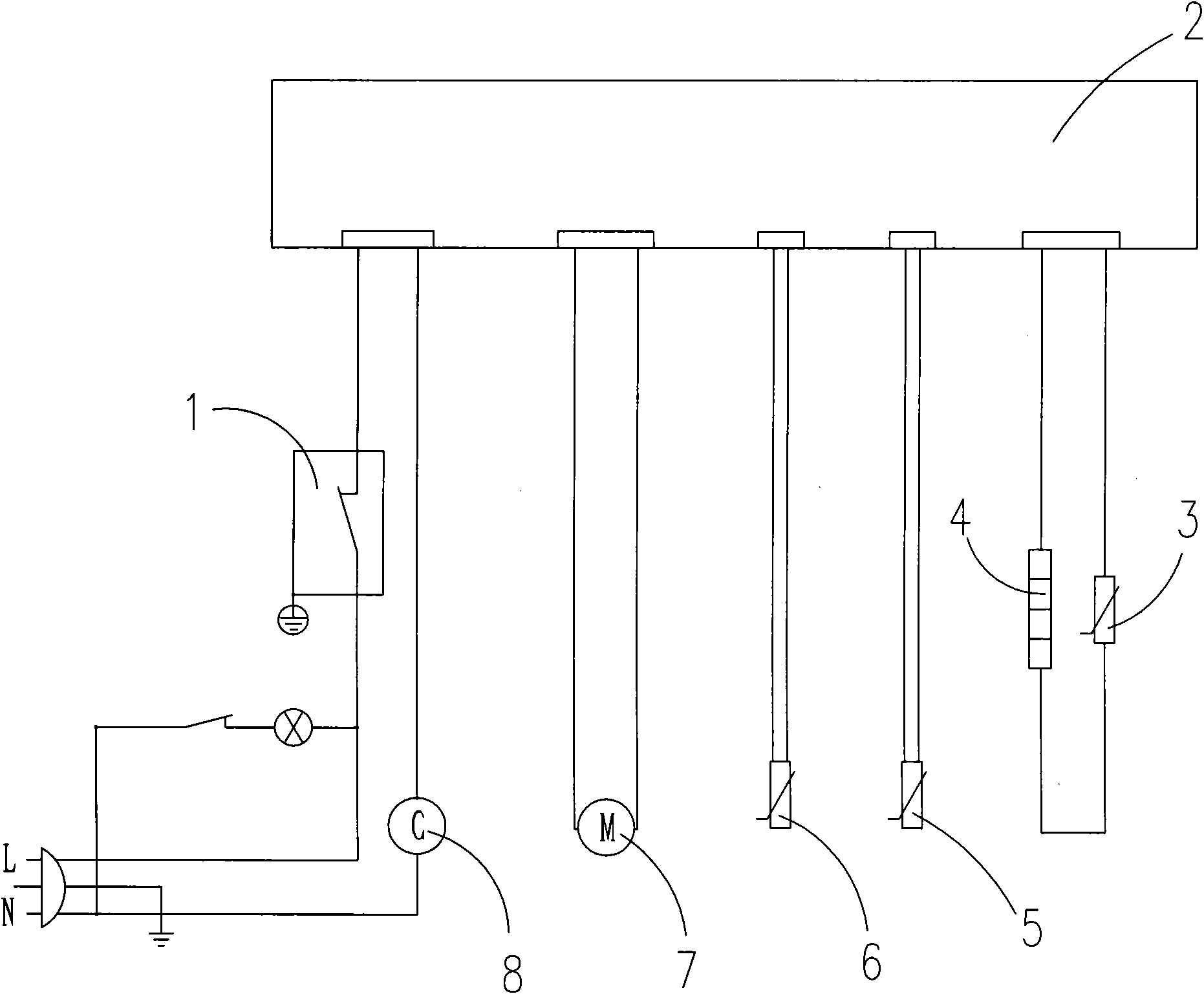

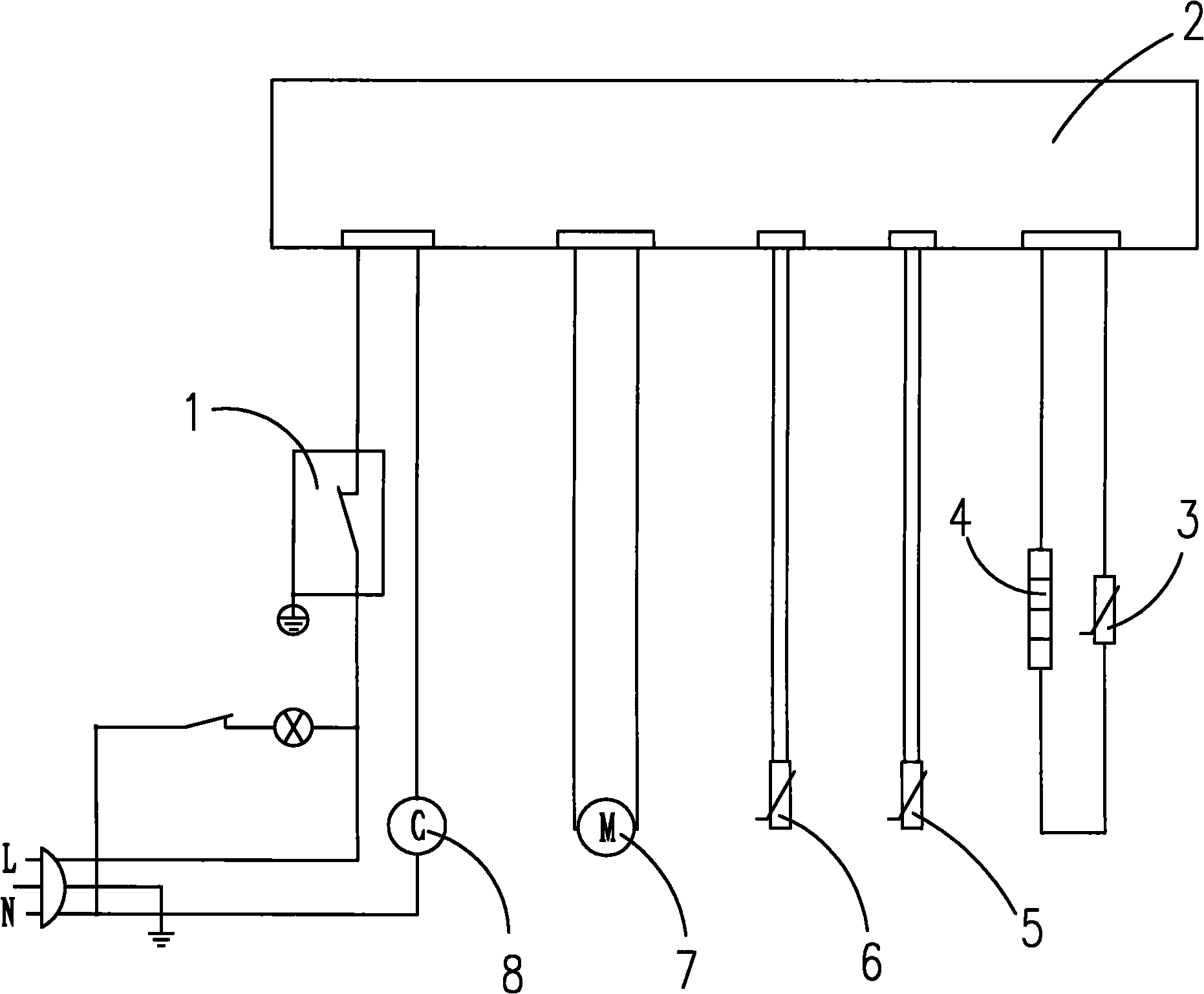

[0013] see figure 1 , the same as the prior art, in the present embodiment, the normal start-stop working state of the compressor 8 and the fan motor 7 is controlled by the conventional thermostat 1 through the control board 2; in the present embodiment, a The electronic temperature probe 6 of the refrigerating room, when the temperature of the refrigerating room is detected by the electronic temperature probe 6 of the refrigerating room reaches the set temperature, the control panel 2 controls the compressor 8 and the fan motor 7 to stop; The defrosting circuit composed of the heater 4 and the defrosting fuse 3; when the defrosting probe 5 detects that the set value is reached, the controller 2 controls the heater 4 and the defrosting fuse 3 to disconnect.

[0014] working principle:

[0015] The normal start-stop state of the compressor 8 and the fan motor 7 controlled by the thermostat 1 through the control board 2 refers to; during normal operation: when the thermostat 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com