Collecting pipe structure for heat exchanger

A technology for heat exchangers and headers, applied in the field of header structures, can solve problems such as the inability to further improve the heat exchange efficiency of the heat exchanger, achieve good positioning consistency, improve heat exchange efficiency, and reduce eroded products the possible effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

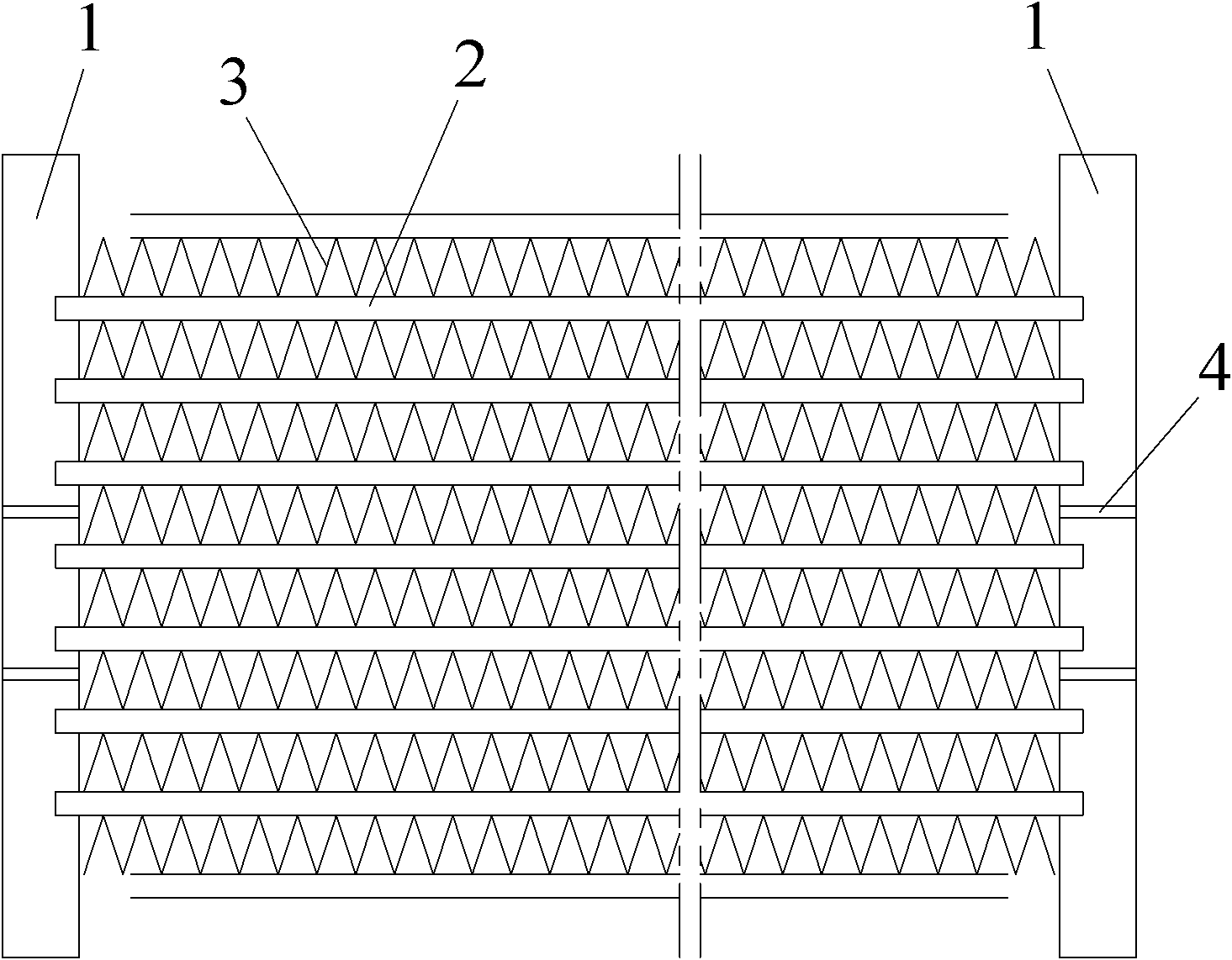

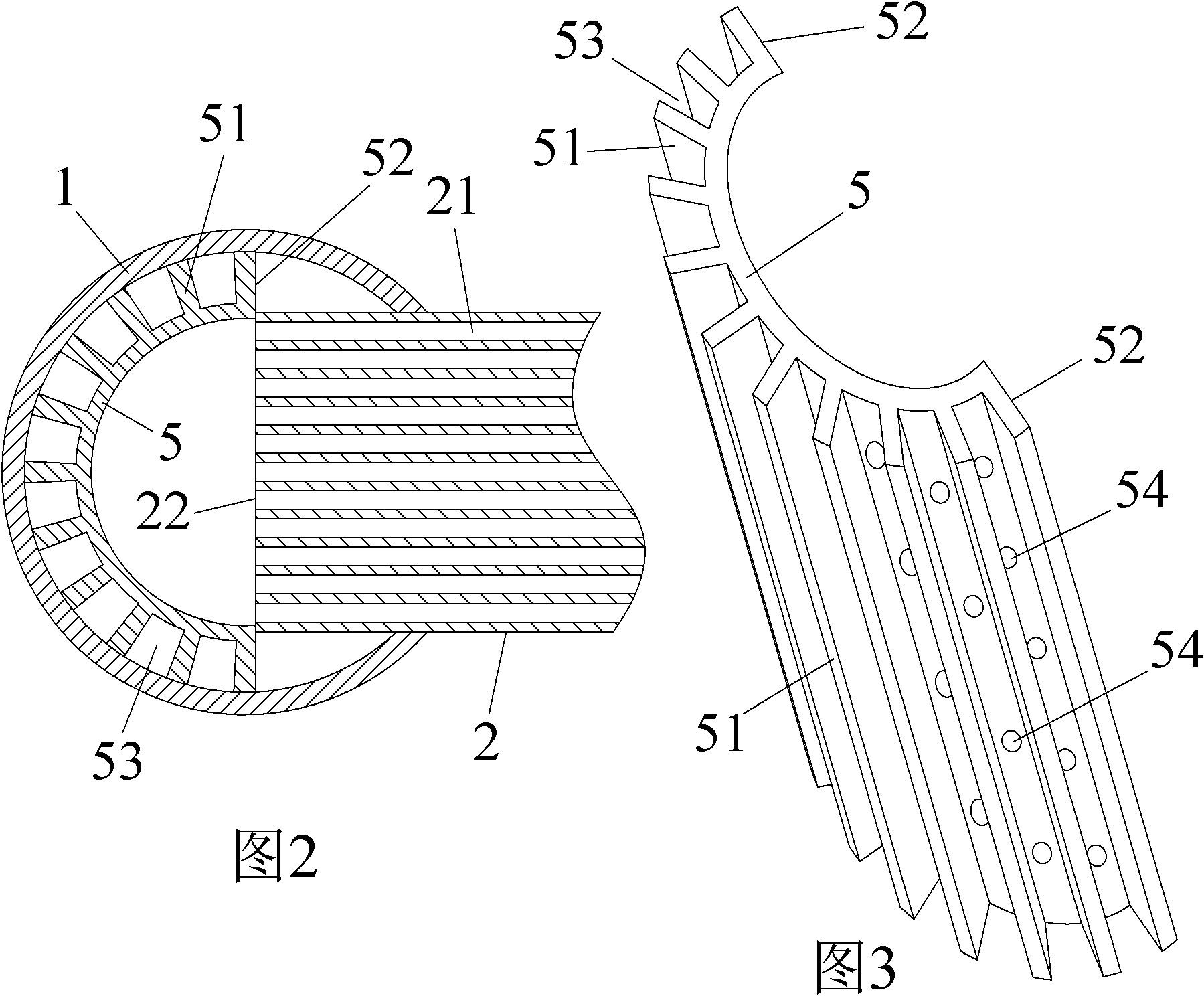

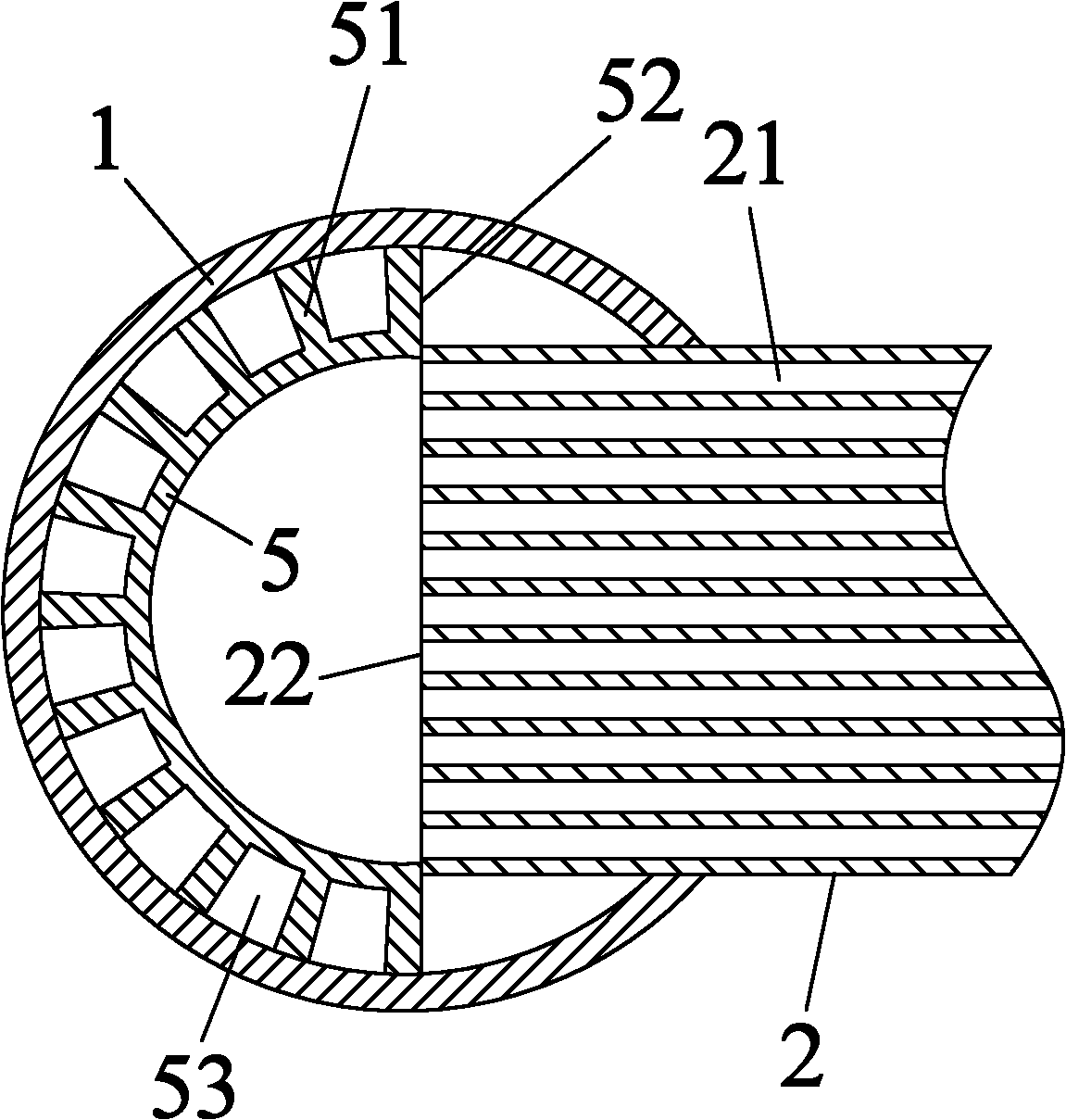

[0012] Example: see figure 1 and figure 2 , the present invention is provided with an interface for inserting the heat dissipation flat tube on one side of the collector, the heat dissipation flat tube is plugged into the collector through the interface, and fins 3 are provided between adjacent flat tubes 2, and the heat dissipation flat tube The microchannel connects the two left and right headers, and there is also a separator 4 in the header 1, which divides the cavity of the header into several small chambers, which is conducive to evenly distributing the medium and improving the heat exchange efficiency of the flat tube . see figure 2 , the inner cavity of the header 1 is provided with a positioning lining 5 on the opposite side of the interface, the inner end surface 22 of the heat dissipation flat tube 2 is set against the positioning surface 52 of the positioning lining 5, and the positioning lining 5 There are several ribs 51 on the outer side, and the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com