Touch screen and electronic device therewith

A technology of electronic devices and touch screens, applied to the conductive layer on the insulating carrier, the structure of the telephone, and the processing of electrical digital data, etc., can solve the problem that the frame cannot be further reduced, achieve the effect of reducing the width and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

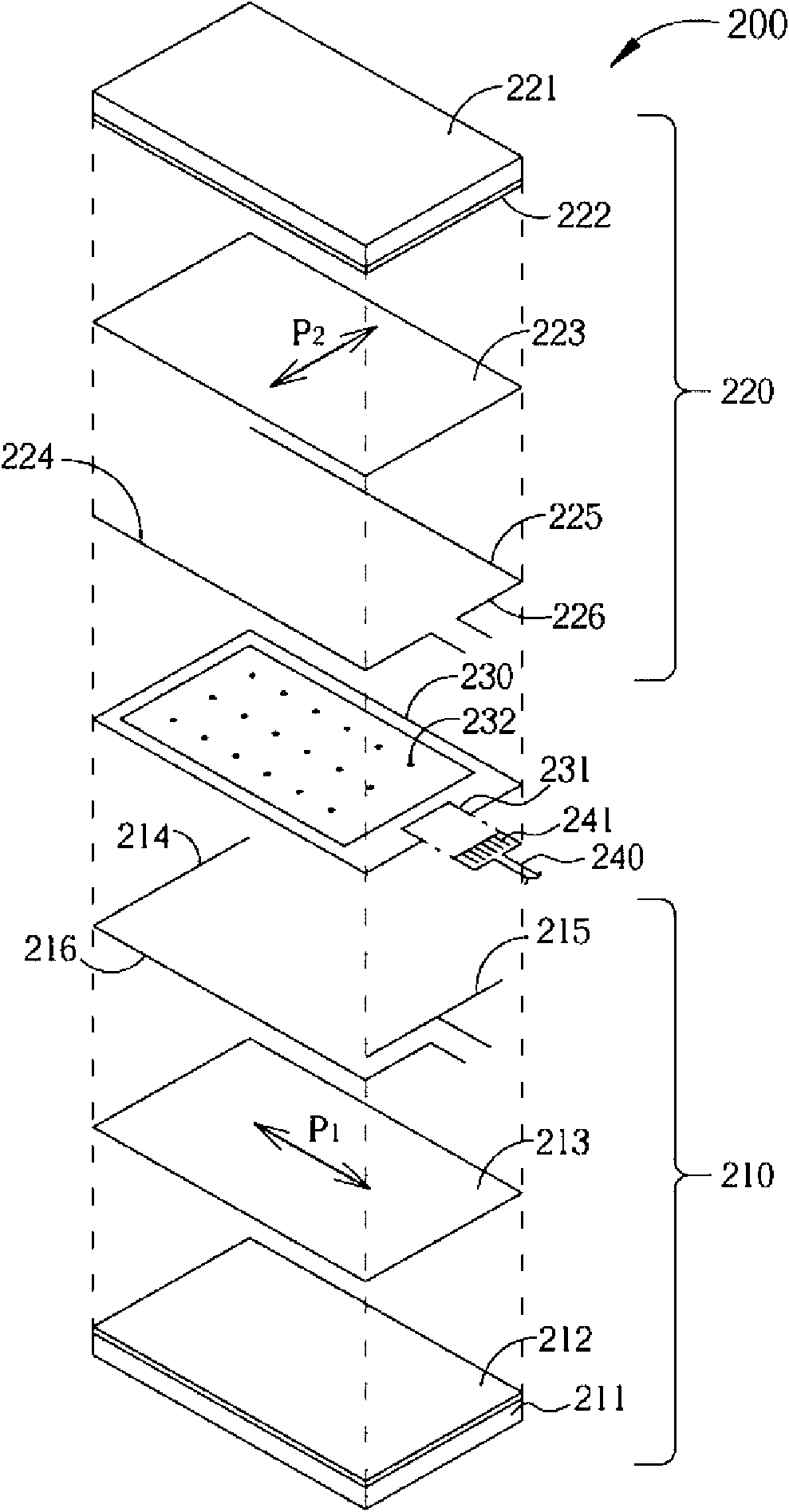

[0027] figure 2 It is a combination diagram of a preferred embodiment of the resistive touch screen of the present invention. The touch screen 200 is formed by stacking two conductive films 210, 220, and the two conductive films 210, 220 are bonded and fixed with an annular colloid layer 230, and a plurality of insulating spacers 232 (spacers) are evenly distributed in the center, so that the two conductive films 210, 220 maintain a fixed distance.

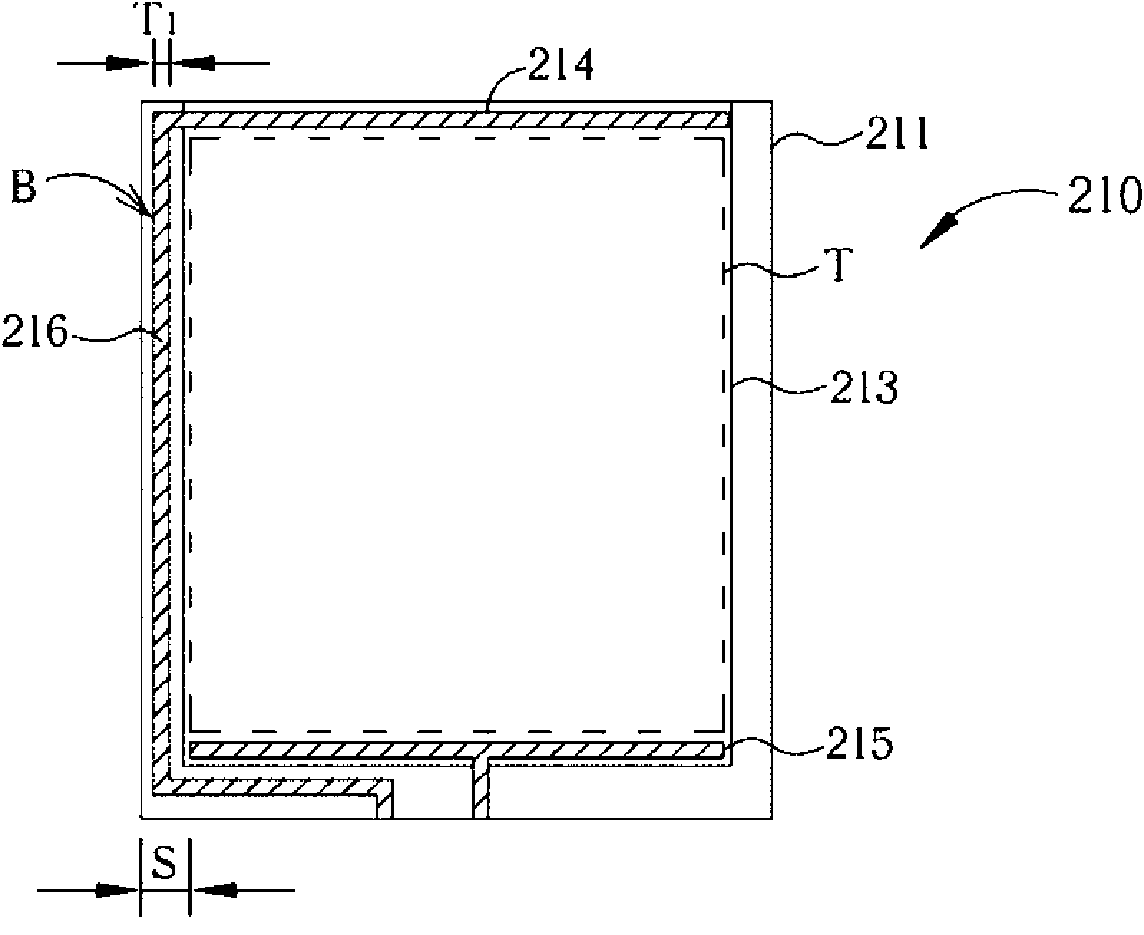

[0028] The conductive film 210 includes a substrate 211 , and a conductive layer 213 is bonded and fixed on the surface of the substrate 211 through the colloid layer 212 . An electrode 214 , an electrode 215 and peripheral wires 216 are further disposed on the surface of the conductor layer 213 . Wherein the electrodes 214 , 215 are arranged parallel to each other on opposite side edges of the conductive layer 213 . The peripheral wire 216 is an extension of the electrode 214 , which extends in parallel along the outer edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com