Device for adjusting bending of cross rod for rail wagon

A technology for railway wagons and crossbars, which is applied in the field of bending and repairing equipment for railway wagon crossbars, and can solve problems such as the loss outweighs the gains, flattened crossbars, and inability to translate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

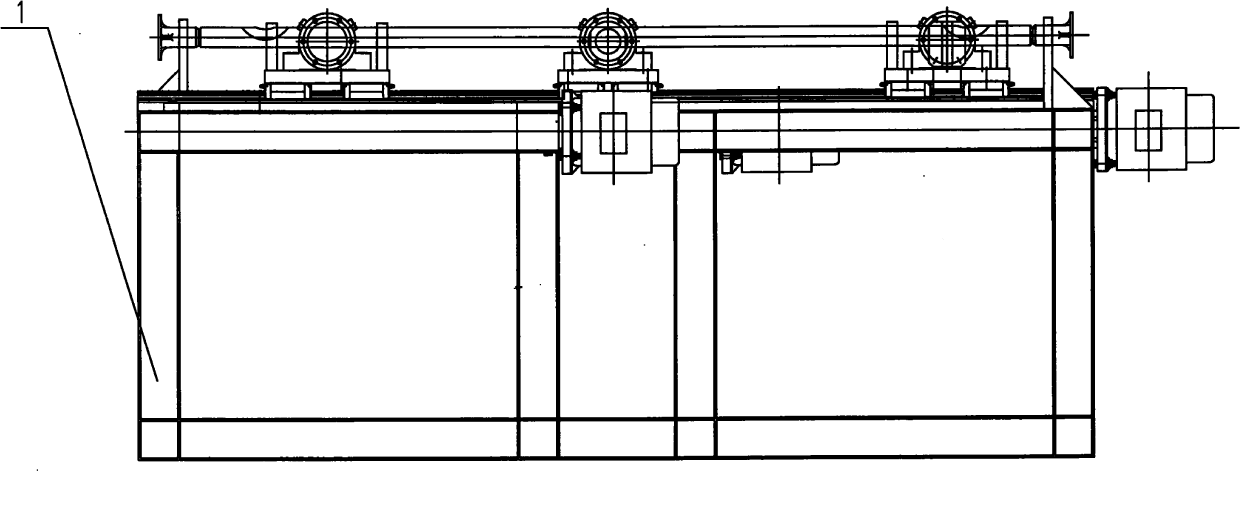

[0021] The equipment for bending and repairing the cross bar of railway wagons comprises: an underframe 1, the two ends of the underframe are connected to the cross bar mounting seats 2, and a set of parallel beams 3 are respectively connected to both sides of the underframe, and each set of Install the track mount 4 on the smooth beam, the slide guide 5 is installed on the track mount, the end adjustment device 6 is connected to the guide rail slide block 14 on the slide guide, wherein one set of the slide guide The middle adjustment device 7 is connected through the guide rail slider 15 .

Embodiment 2

[0023] In the described equipment for repairing the bending of cross rods of railway wagons, the described end repairing device includes an end repairing device mounting plate 8, and the end driving screw 9 is connected to the bottom of the end repairing device mounting plate. The end drive screw rod is connected to the end drive motor 10, the hydraulic cylinder 11 is installed on the mounting plate of the end adjustment device, the piston rod of the hydraulic cylinder is connected to the profiling fixture 12, and the fixing fixture 13 is connected with the The profiling fixture is aligned and installed on the mounting plate of the end adjustment device.

Embodiment 3

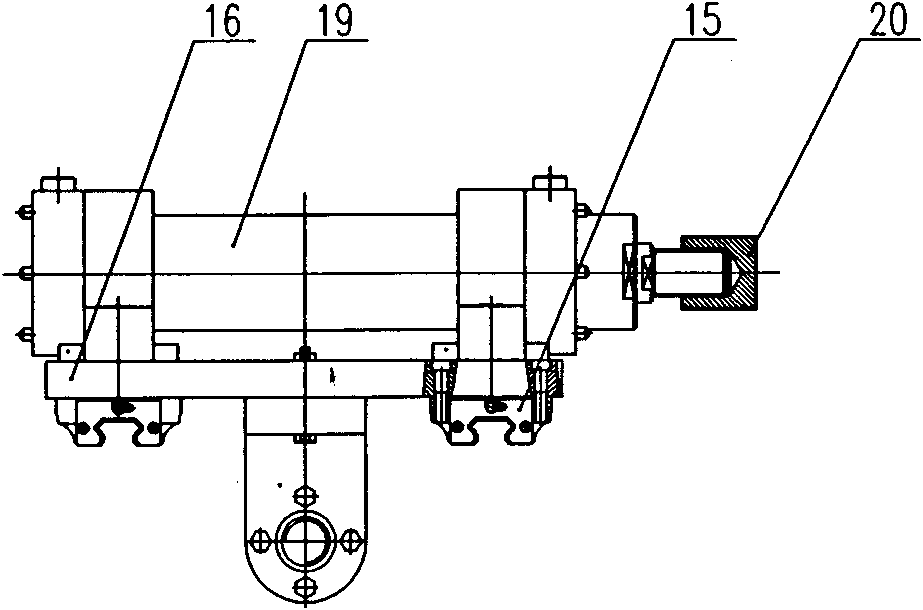

[0025] Said railway wagon cross bar bending adjustment equipment, said middle adjustment device includes a middle adjustment device mounting plate 16, the middle transmission screw rod 17 is connected to the bottom of said middle adjustment device installation plate, and said middle transmission The screw mandrel is connected with the driving motor 18 in the middle, and the hydraulic oil cylinder 19 is installed on the mounting plate of the middle adjusting device, and the piston rod of the hydraulic oil cylinder is connected with the chuck 20 .

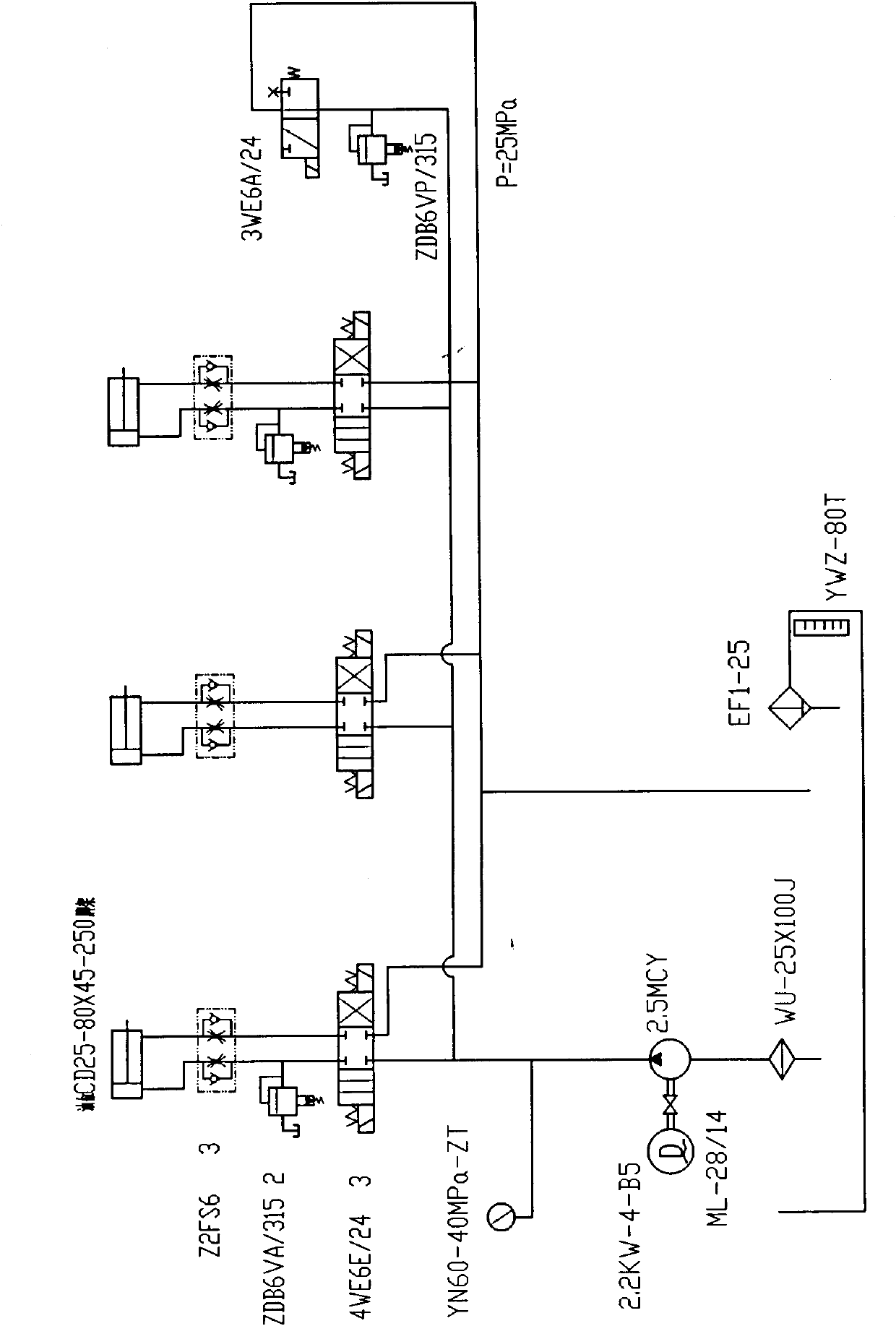

[0026] The hydraulic system of the present invention is composed of a hydraulic pump station, a system oil circuit, an oil circuit of an end repairing device, and an oil circuit of a middle repairing device. The hydraulic pump station includes oil suction filter, oil pump, motor, manifold, pressure gauge, vernier and other accessories. The integrated block is used to install relevant hydraulic valves and connect the oil circuit of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com