Heat insulated electric welding pliers

An electric welding tongs, together technology, applied in the direction of welding rod characteristics, electrode support devices, etc., can solve the problems of spring gaskets easily damaged by heat, unable to protect the spring, the length of the conductor, etc., to reduce the heat transfer area, save the amount, and length. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

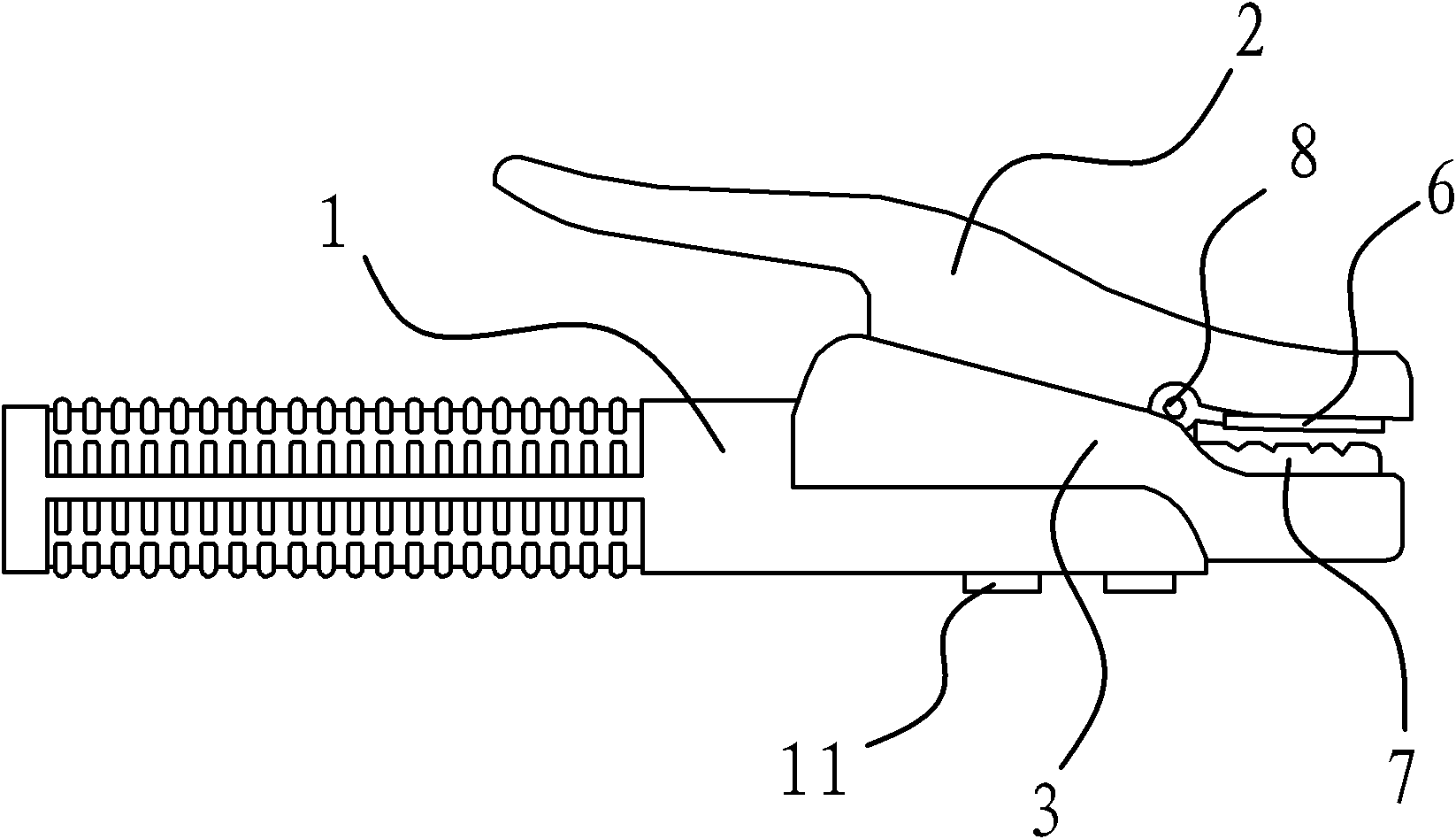

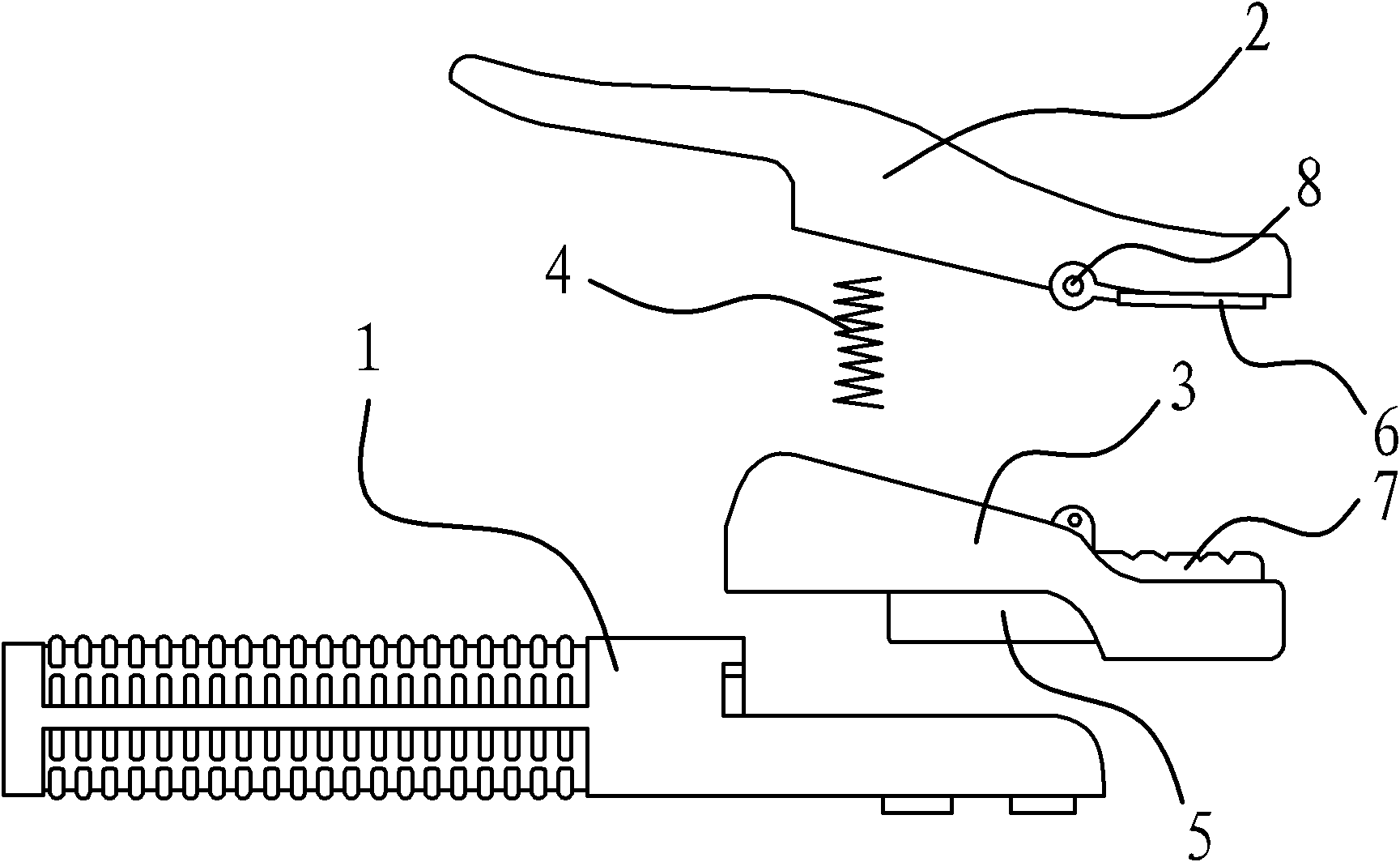

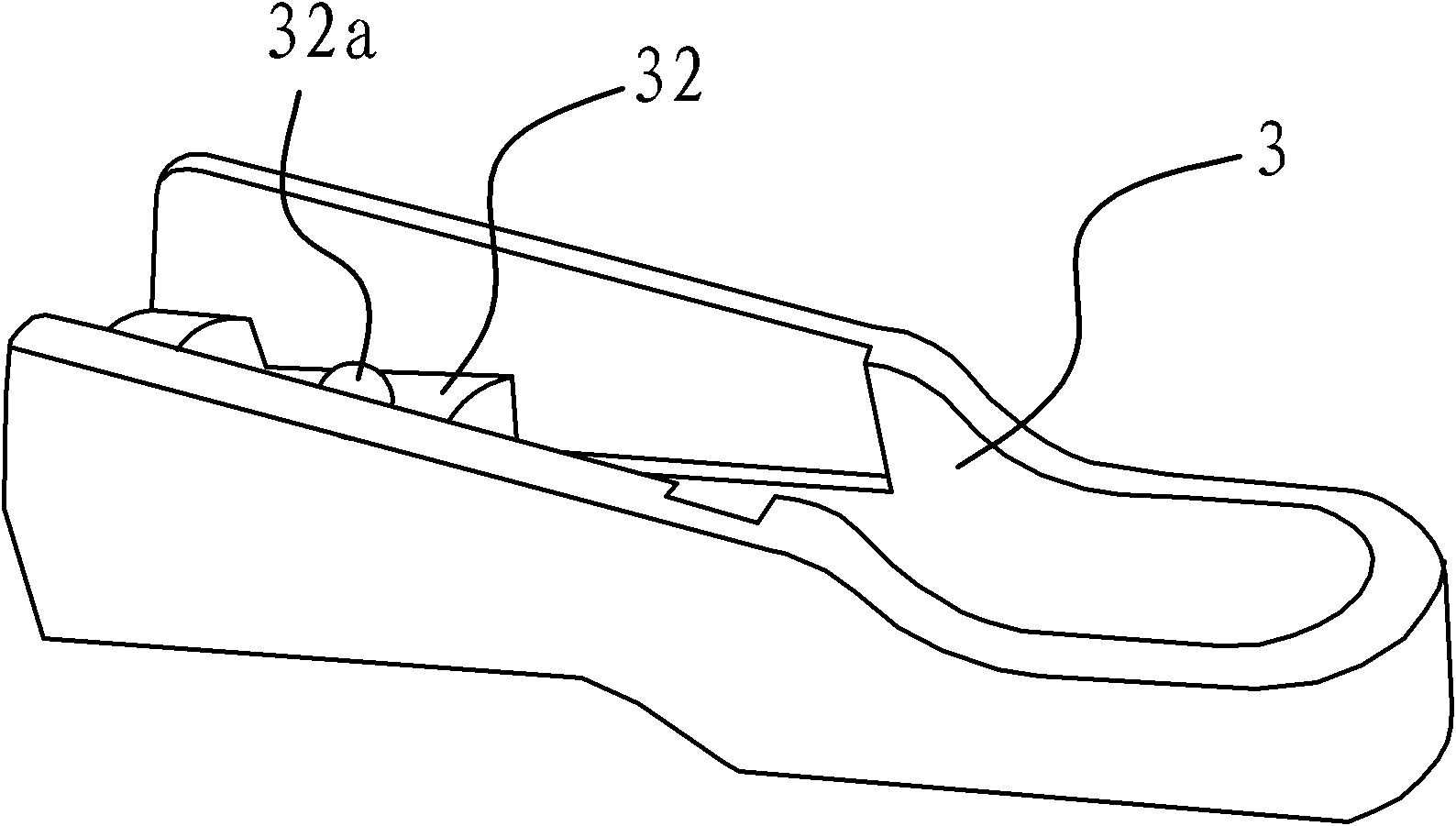

[0033] Such as figure 1 and figure 2 As shown, the heat-insulated electric welding tongs include a handle 1, a handle 2 and a metal connector 5 arranged at the front end of the handle 1. The metal connector 5 connects and fixes the handle 2, the handle 1, and the lower copper head 7 of the electric welding tongs together. Components for connecting cables. The metal connector 5 and the handle 2 are rotationally connected by a pin shaft 8, and the handle 2 and the metal connector 5 are respectively fixed with an upper copper head 6 and a lower copper head 7, and an upper copper head 6 and a lower copper head 7 There is a reset mechanism between the handle 1 and the handle 2, and a shielding member 3 made of insulating and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com