Resistor cap-removing machine

A technology of resistors and caps, applied in resistors, resistor manufacturing, circuits, etc., can solve problems such as defective products, increase production costs of enterprises, and size discrepancies, and achieve the effect of reducing production costs, improving work efficiency, and realizing reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

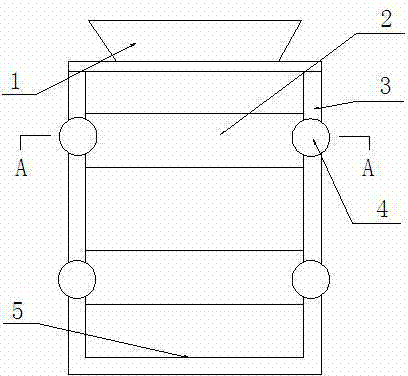

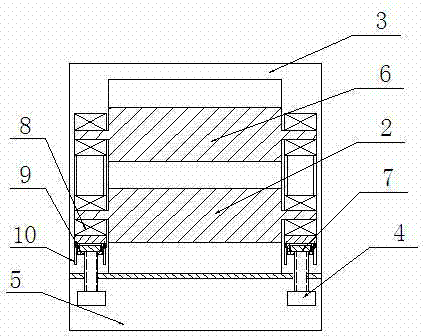

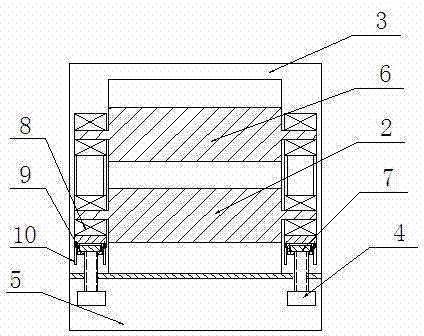

[0012] Depend on figure 1 , figure 2 It can be seen that a resistance capping machine comprises a frame 3, and the frame 3 is at least provided with a pair of fixed rollers 6 and movable rollers 2 driven by power to rotate in opposite directions and a spacer for adjusting the distance between the fixed rollers 6 and the movable rollers 2. Adjustment device. In order to ensure the cap removal effect in this embodiment, two pairs of fixed rollers 6 and movable rollers 2 driven by power to rotate in opposite directions are provided on the frame 3, and are arranged up and down, and each pair of fixed rollers 6 and movable rollers 2 are arranged horizontally .

[0013] In the present invention, in order to increase the friction and extrusion force between the roller and the metal cap, the surfaces of the fixed roller 6 and the movable roller 2 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com