Positively engaging shifting element which can be hydraulically or pneumatically actuated

A shift element, hydraulic technology, applied in the direction of transmission elements, elements with teeth, fluid-driven clutches, etc., can solve the problems of increased conversion clearance, driving comfort and noise impact, life and efficiency disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

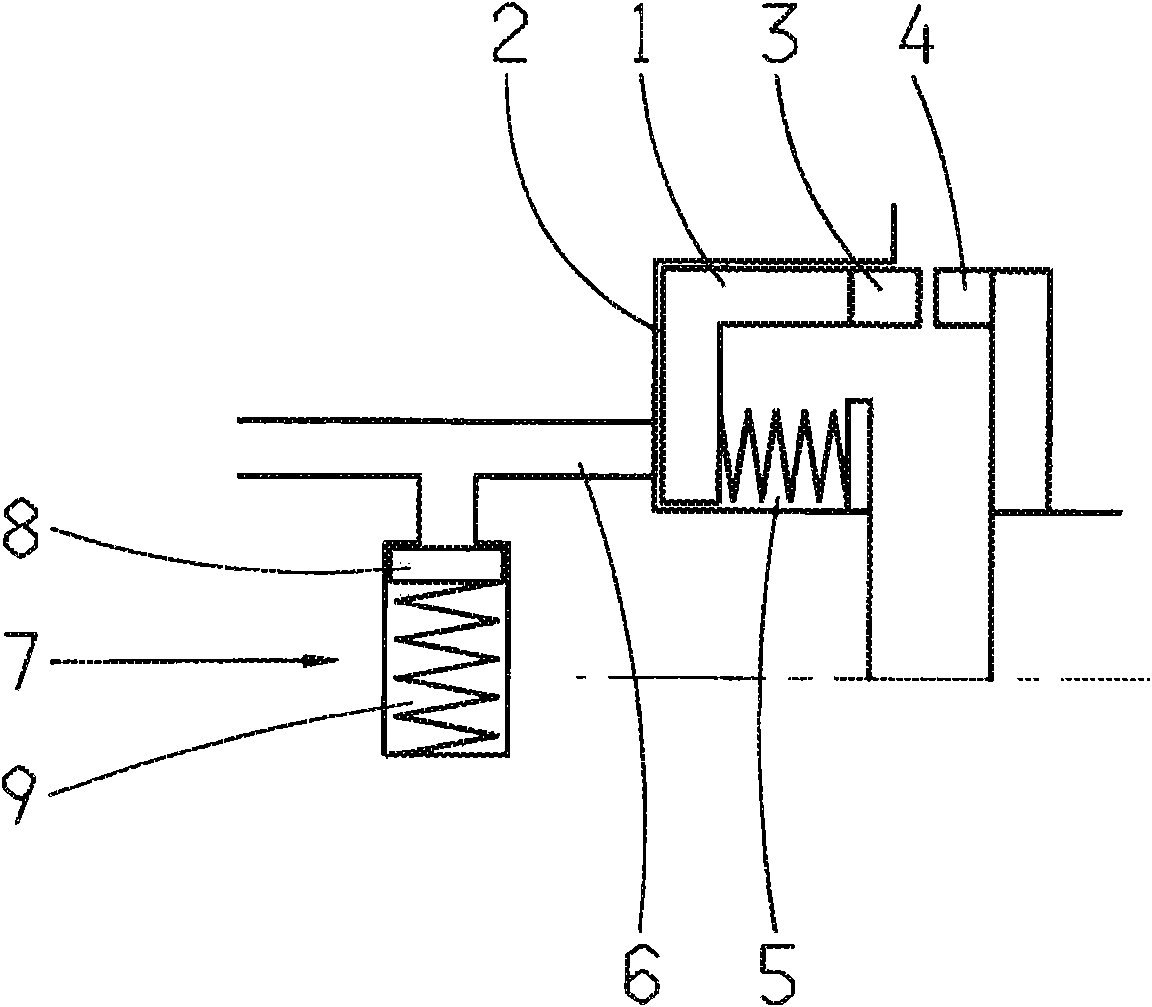

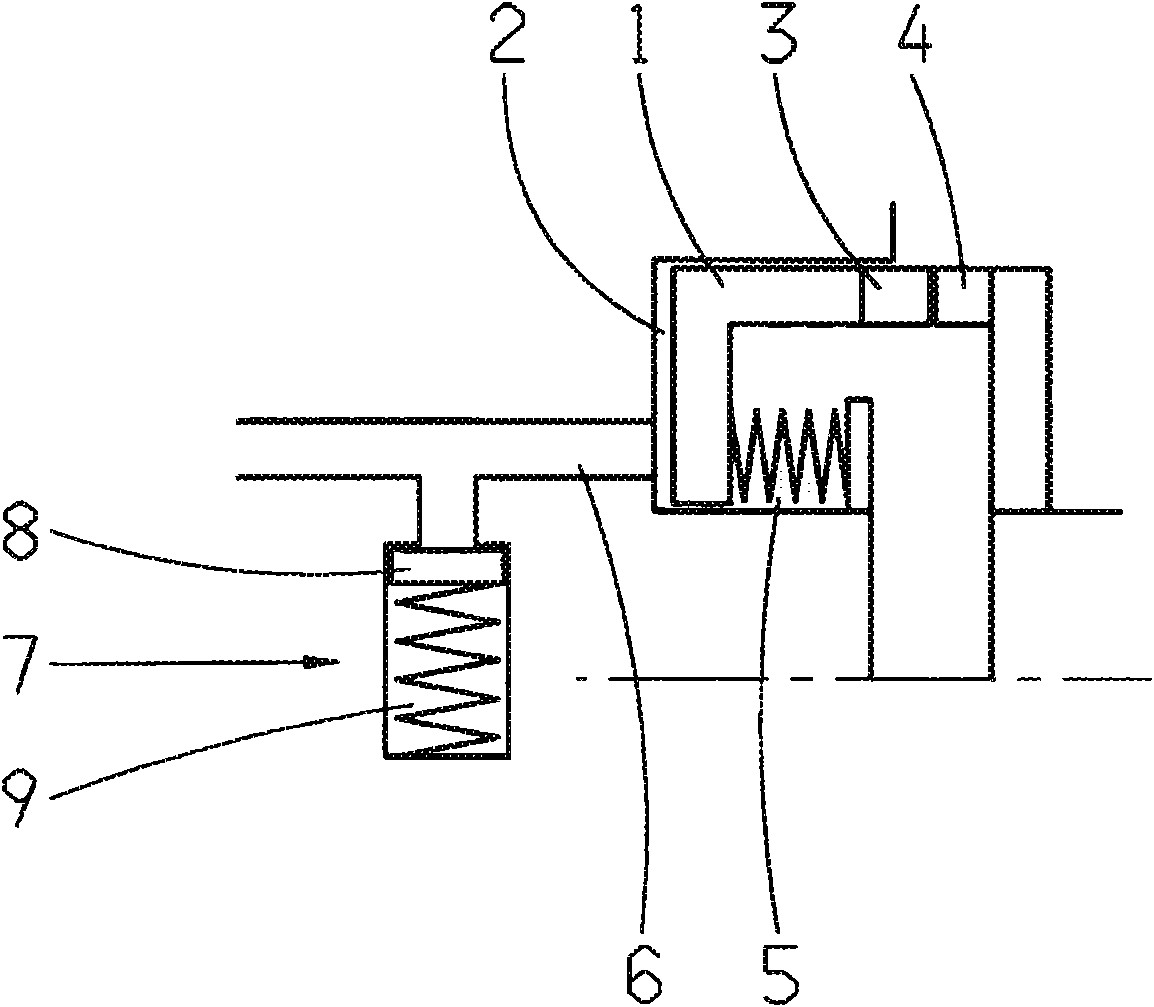

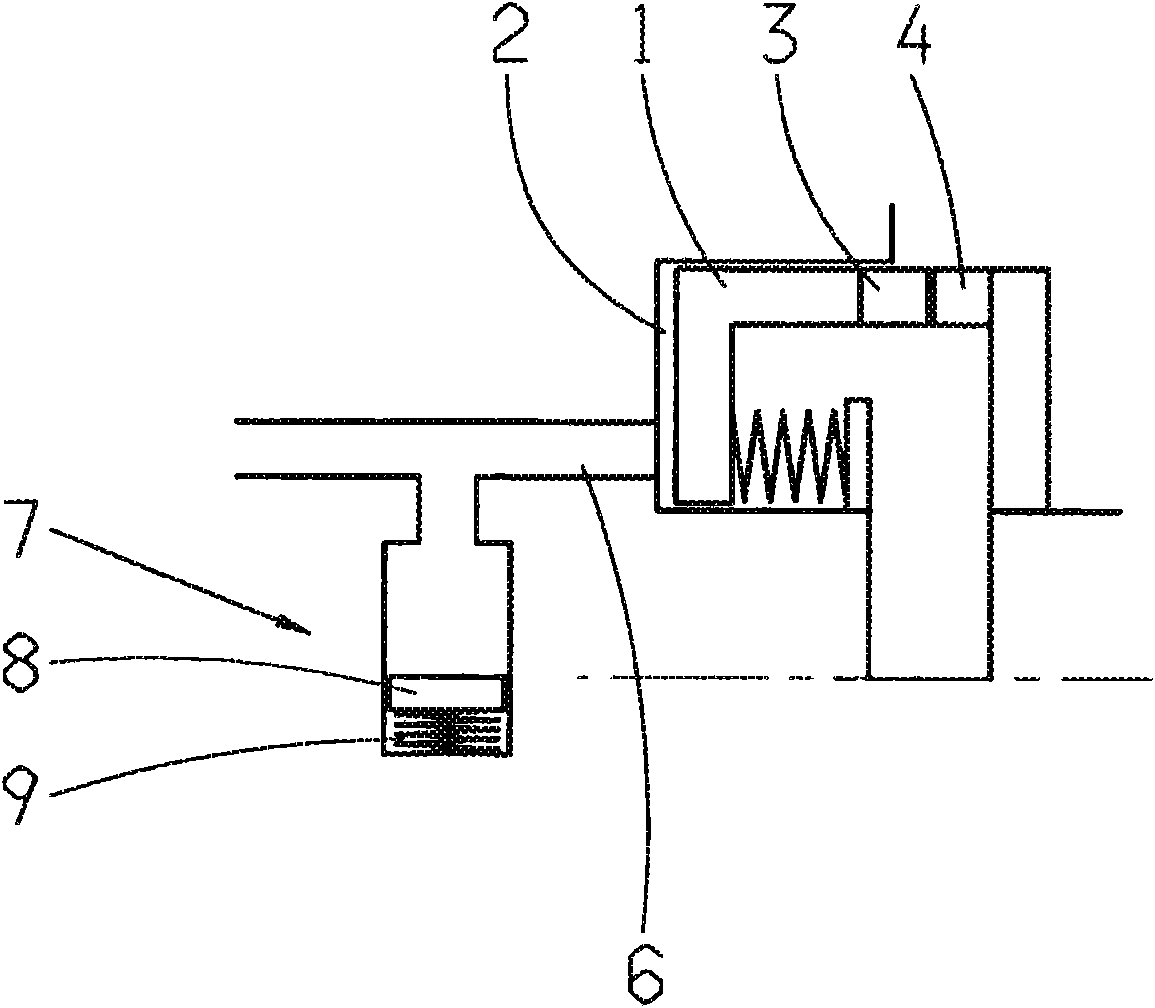

[0026] exist figure 1 An exemplary assembly variant of the hydraulically or pneumatically actuatable form-fitting shifting element according to the invention is shown in .

[0027] The shifting element comprises a hydraulically or pneumatically actuatable piston 1 having a piston chamber 2 in which a hydraulic or pressure medium is located, the shifting element also comprising pawls 3 and counter pawls The tooth 4 and the claw tooth 3 are embedded in the pair of claw teeth 4 in the inserted state.

[0028] The shifting element also includes a spring 5 acting as a release spring (Ausrückfeder) for pushing back the claws 3 (for the open state of the shifting element in the depressurized state, this corresponds to the embodiment shown mode) or inward (for the state of the shift element in the depressurized state is closed), wherein the spring 5 acts against the piston 1 when the piston 1 is hydraulically or pneumatically operated. When the shifting element is closed or engaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com