Double-color roller printing machine matched with fixed-step-length stepping traction equipment

A technology of traction equipment and printing machines, which is applied to printing machines, rotary printing machines, printing, etc., and can solve problems such as high cost, long paper winding, and the impact of packaging color registration on the plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

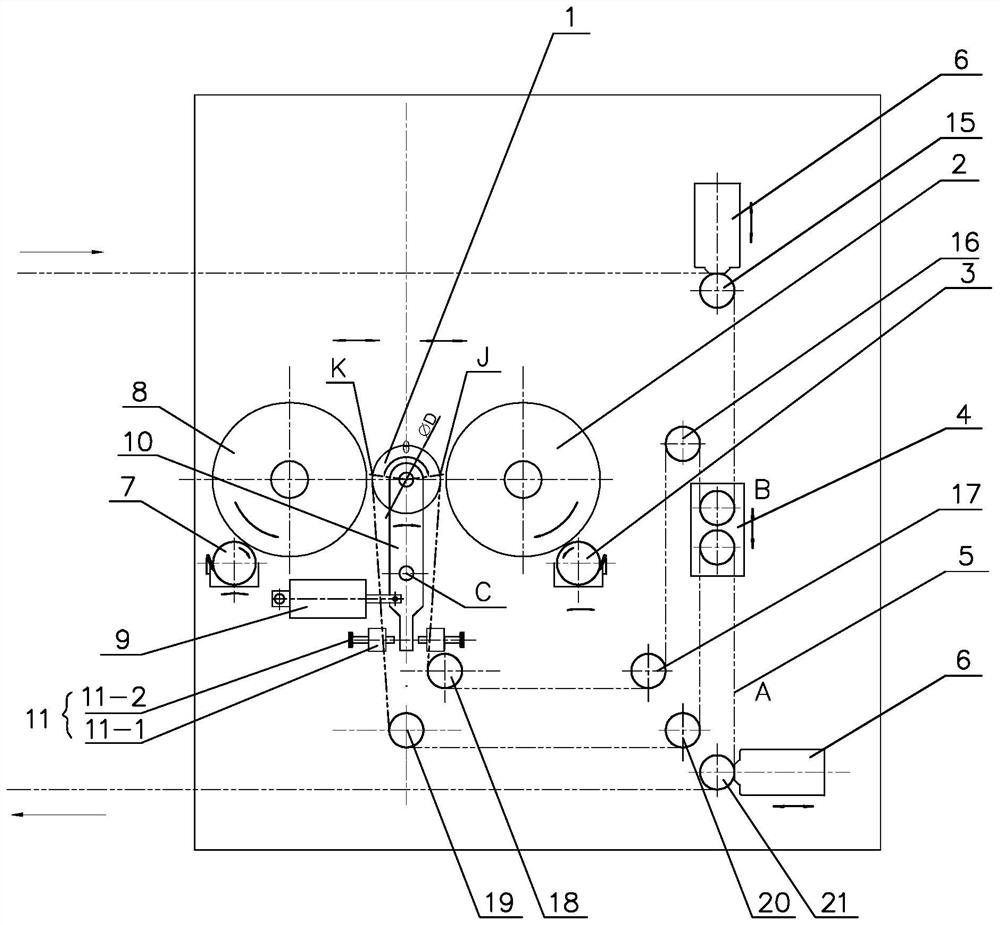

[0067] like figure 1 As shown, the present invention is a two-color roller printing machine matched with fixed-step stepping traction equipment, including:

[0068] A guiding device for guiding the progress of the paper 5 when the traction device pulls the paper 5 to step;

[0069] The first printing cylinder 2, whose rotation is driven and controlled by a motor;

[0070] The second printing cylinder 8, whose rotation is driven and controlled by a motor;

[0071] The printing cylinder 1 is located between the two printing cylinders and can move relative to the two printing cylinders respectively;

[0072] The paper feed roller 4 moves between the first position and the second position during the interval between the steps of the traction device, and drives the paper 5 to reciprocate;

[0073] When the paper feed roller 4 moves from the first position to the second position, the printing cylinder 1 is attached to the surface of the first printing cylinder 2 (so that the pape...

Embodiment 2

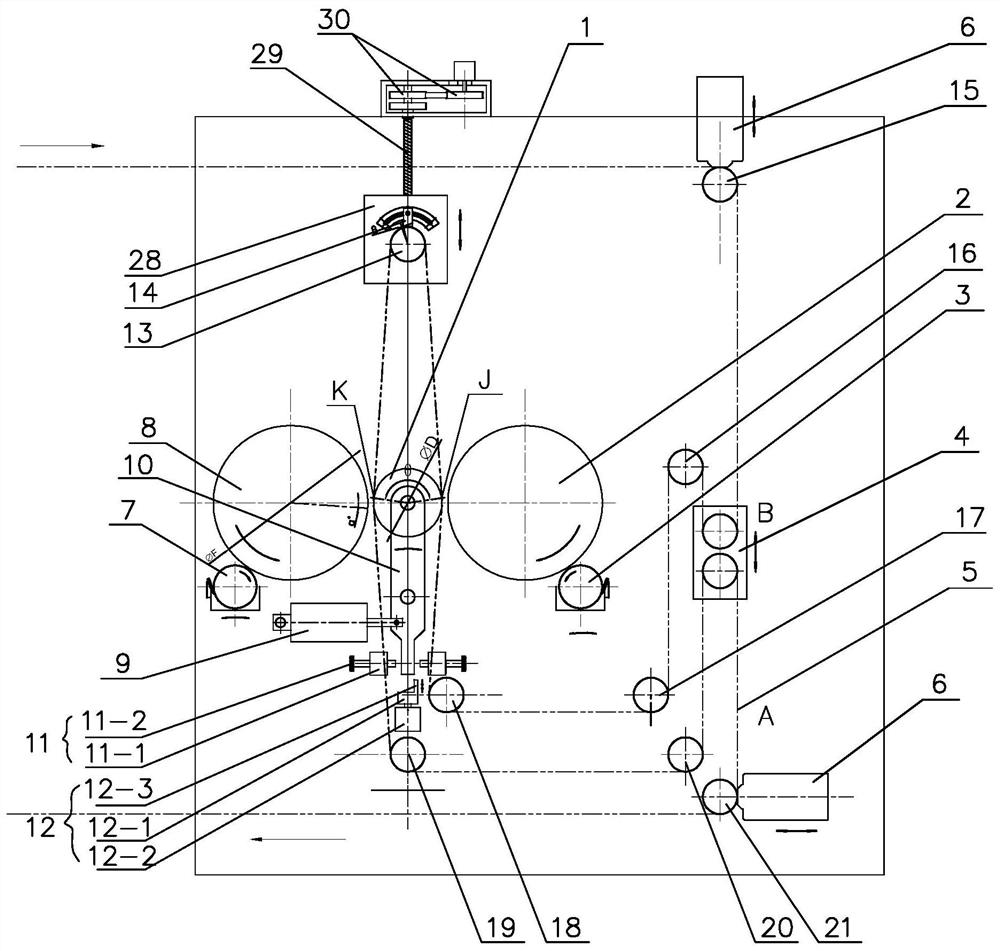

[0094] like image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

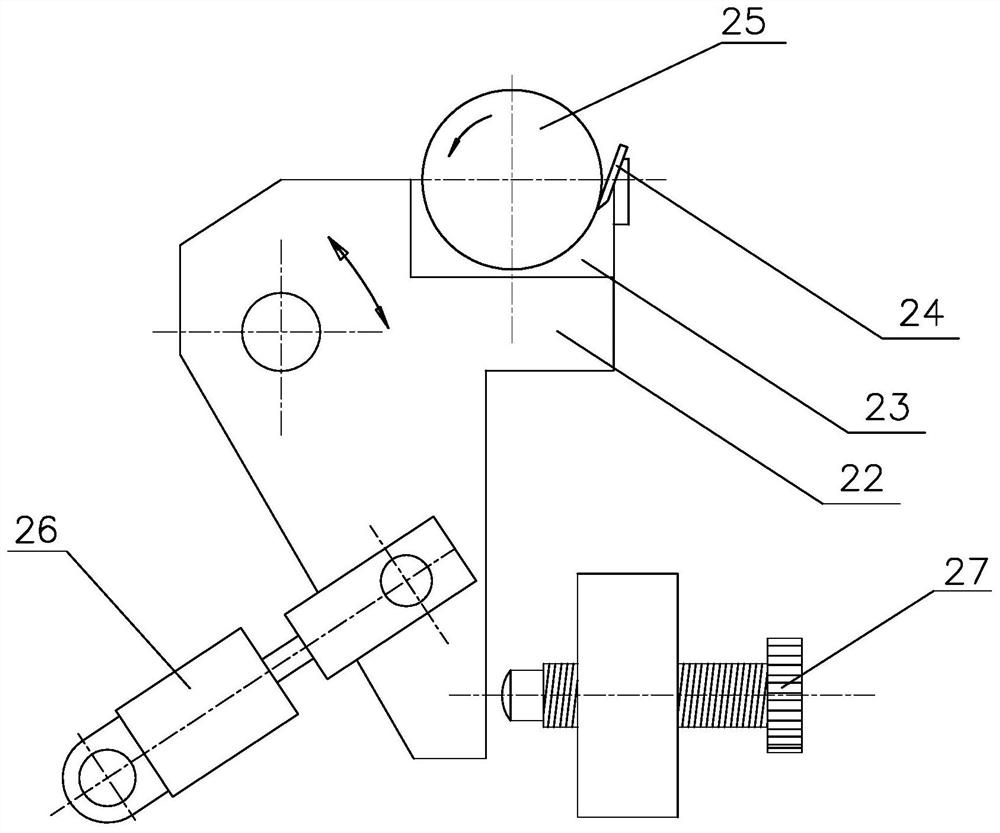

[0095] The printing machine also includes an adjusting roller 13 as one of the paper 5 conveying rollers, which can move relative to the printing cylinder 1 to adjust the distance between it and the printing cylinder 1. The paper winding length between the tangent points J and K of the two printing cylinders can increase the residence time after printing, ensure the ink is dry, and avoid the printing ink from polluting the printing machine or paper due to undried printing ink.

[0096] When carrying out two-color printing, the winding length between the printing cylinder 1 and the tangent points J and K of the two printing cylinders is nH; where n is an integer greater than or equal to 1, and H is the moving step of the traction device, where The distance between the paper feed roller 4 at position A and position B is L / 2 (that is, the distance between the first position...

Embodiment 3

[0106] like Figure 5 As shown, this embodiment is basically the same as Embodiment 2, the difference is:

[0107] In Embodiment 2, the relative movement between the printing cylinder 1 and the two printing cylinders (the first printing cylinder and the second printing cylinder) is realized by the swinging of the printing cylinder 1 (the two printing cylinders do not move); in this embodiment The position of the printing cylinder 1 is fixed, and the first printing cylinder 2 and the second printing cylinder 8 are arranged on the frame of the printing machine through the printing cylinder swing mechanism, so that the two printing cylinders can swing relative to the printing cylinder 1 . In addition to realizing the function of Embodiment 2 (certainly, since the printing cylinder is fixed, there is no need to realize the printing cylinder reset function), this embodiment can also realize that the first printing cylinder 2 and the second printing cylinder 8 are attached to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com