Dielectric barrier discharge pump apparatus and method

A technology of blocking discharge and dielectric layer, which is applied in the field of dielectric barrier discharge pump devices, and can solve the problems of physical installation of pumps, large diameters of pipes or conduits, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the invention, application, or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate similar or corresponding parts and features.

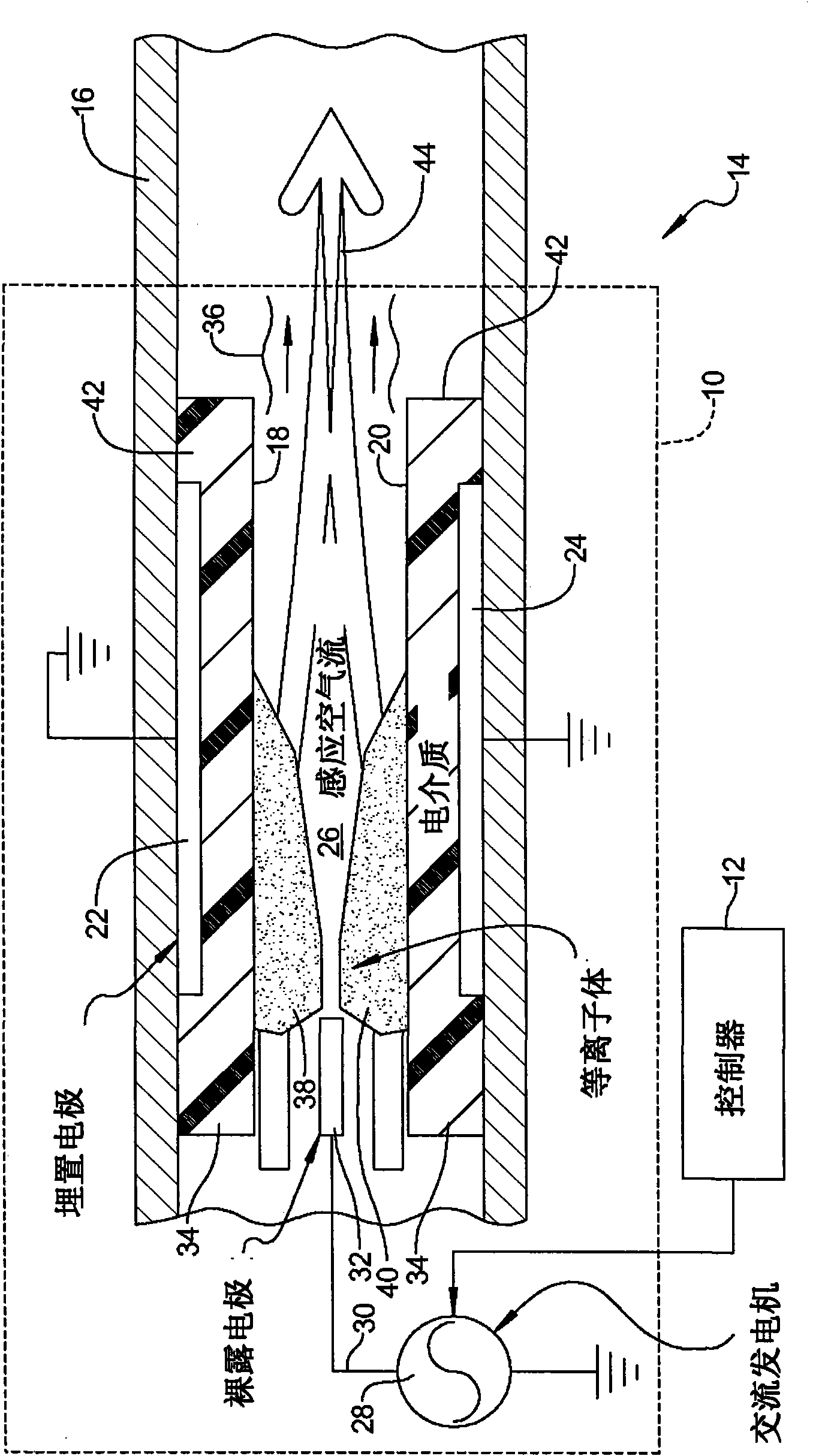

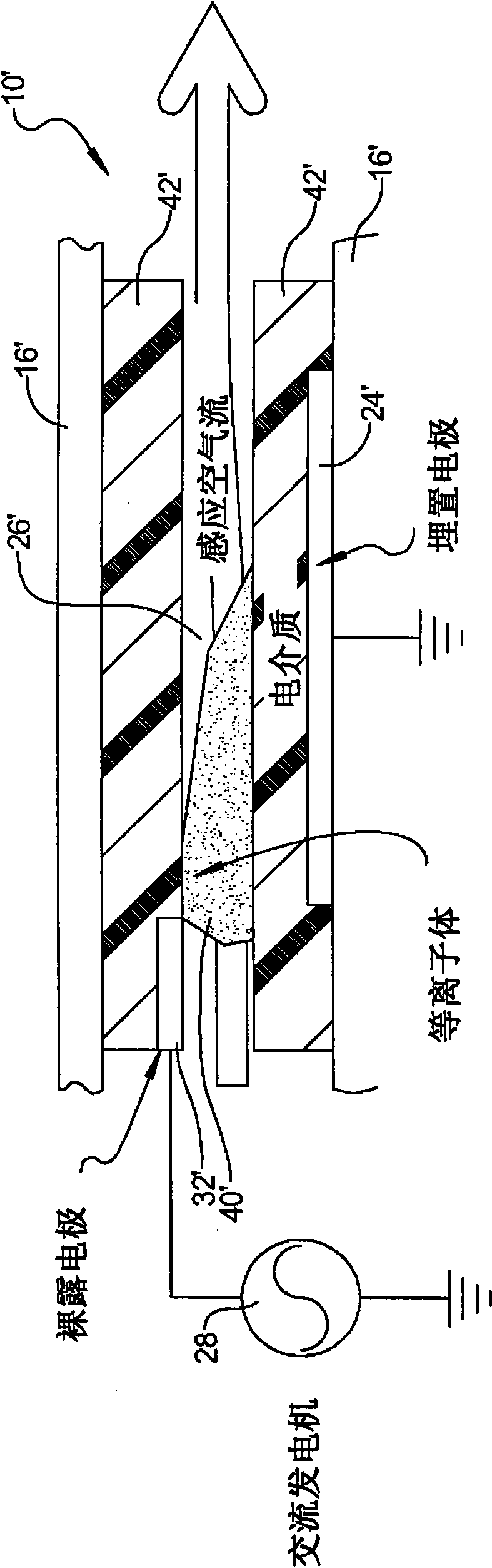

[0023] refer to figure 1 , shows the fluid flow acceleration device 10 . A fluid flow acceleration system 14 is formed using devices connected to the controller 12 . The device 10 may be disposed within a conduit 16 or conduit, or any component or structure in which a contained or semi-contained fluid flow exists, and within which it is desired to accelerate the fluid flow.

[0024] refer again figure 1 , device 10 includes a first dielectric layer 18 affixed to the inner wall of conduit 16, and a second dielectric layer 20 also affixed to the inner wall of conduit 16 in facing (ie opposing) relationship. The first dielectric layer 18 includes a first electrode 22 at least substantially embedded within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com