Heat insulating device and precise hot press

A technology of heat insulation device and hot press, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., and can solve the problems of sliding seats unable to move, clamping, and guide precision drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

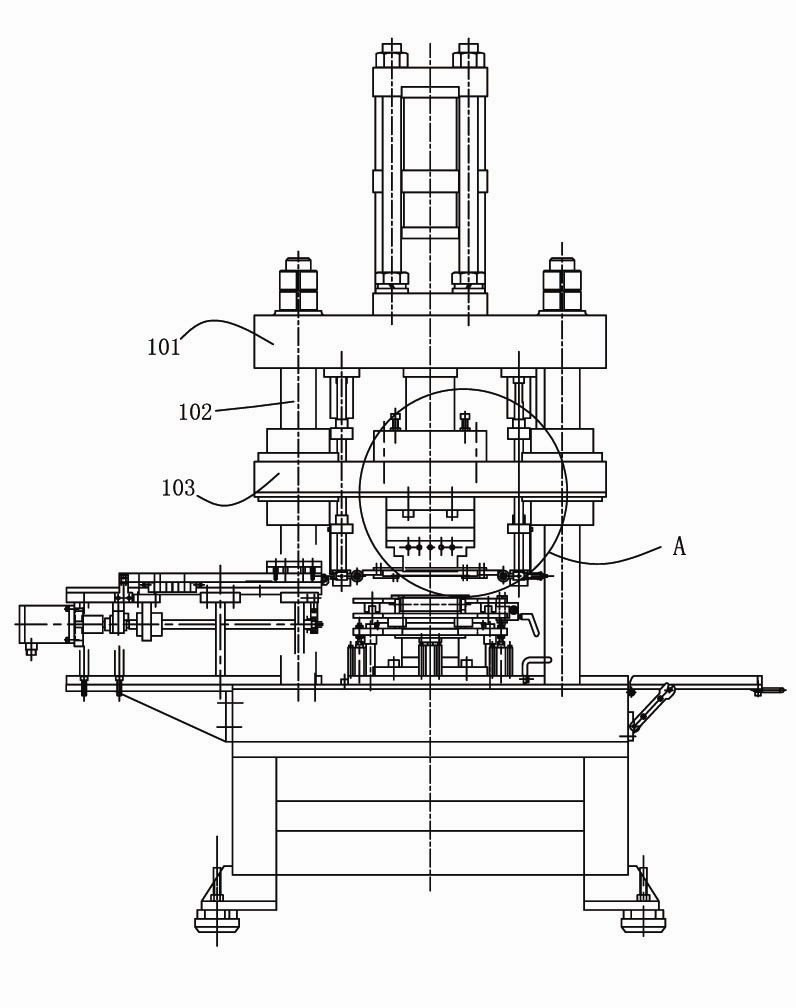

[0021] refer to figure 1 , figure 2 , the first embodiment of the present invention is a precision heat press machine, which already includes the heat insulation device of the present invention, and the heat insulation device of the present invention can be fully implemented with reference to the content of the claims and the content of this embodiment. The thermal device, therefore, does not specifically exemplify an embodiment of the thermal insulation device of the present invention.

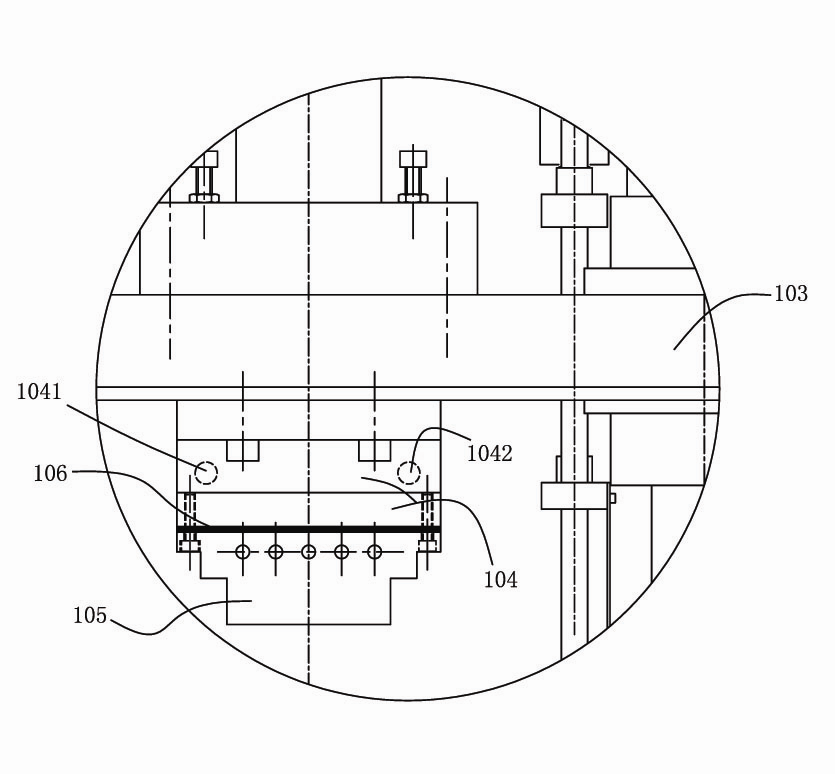

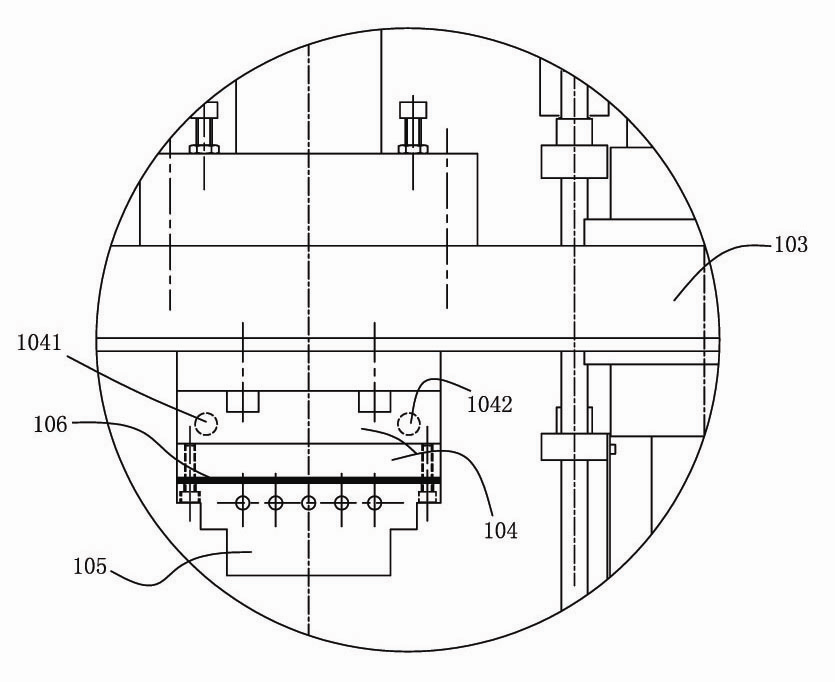

[0022] The precision hot press of this embodiment includes a fixed seat 101 and a sliding seat 103, the sliding seat 103 is connected to the guide column 102 through a guide member, and also includes a thermal pressing head 104 fixedly connected with the sliding seat 103, and a thermal pressing head 105 and a sliding A water cooling plate 104 is also arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com