Extrusion type oil bottle

An extrusion, oil bottle technology, used in bottle filling, bottle/container caps, containers, etc., can solve the problems of residual oil, oil stains that are not easy to clean, and flow out, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

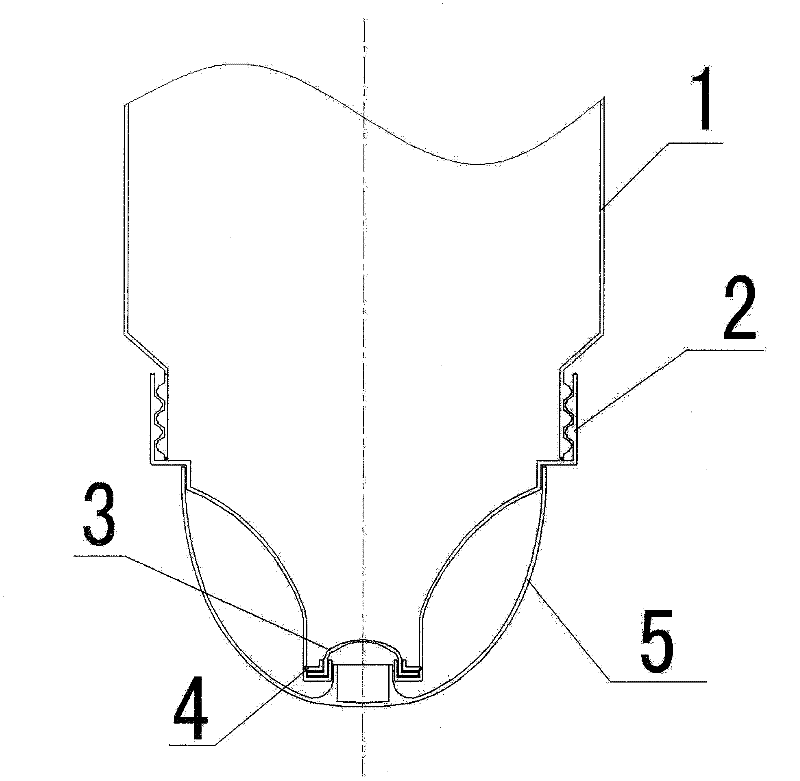

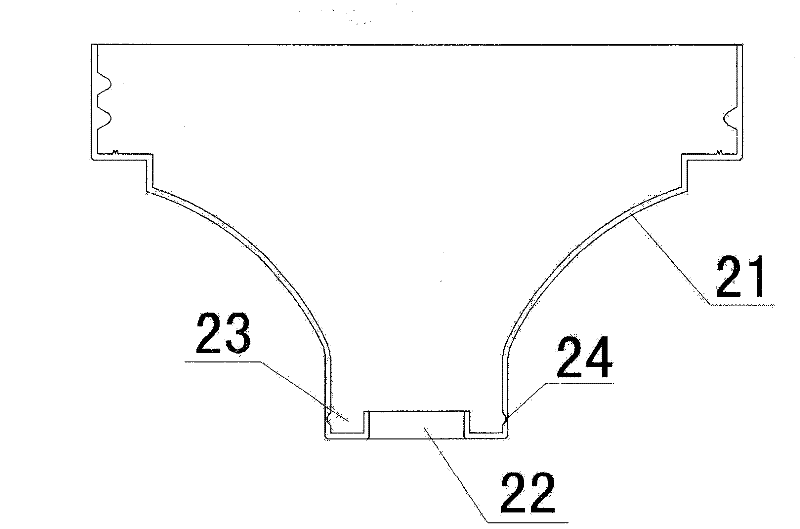

[0022] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an extruded oil bottle, which is composed of a bottle body 1, a bottle cap 2, a diaphragm valve 3, a fixed snap ring 4, and a protective cover 5. The bottle cap 2 also includes an oil outlet nozzle 21, an oil outlet The mouth 22, the U-shaped groove 23 formed by turning the oil nozzle 21 into the bottle, the fixed snap ring groove 24, the fixed snap ring 4 fixes the diaphragm valve 3 on the U-shaped groove 23, that is, the oil outlet 21 is rolled into the bottle The formed U-shaped groove 23 is equipped with a membrane valve 3 that is arched toward the inside of the bottle.

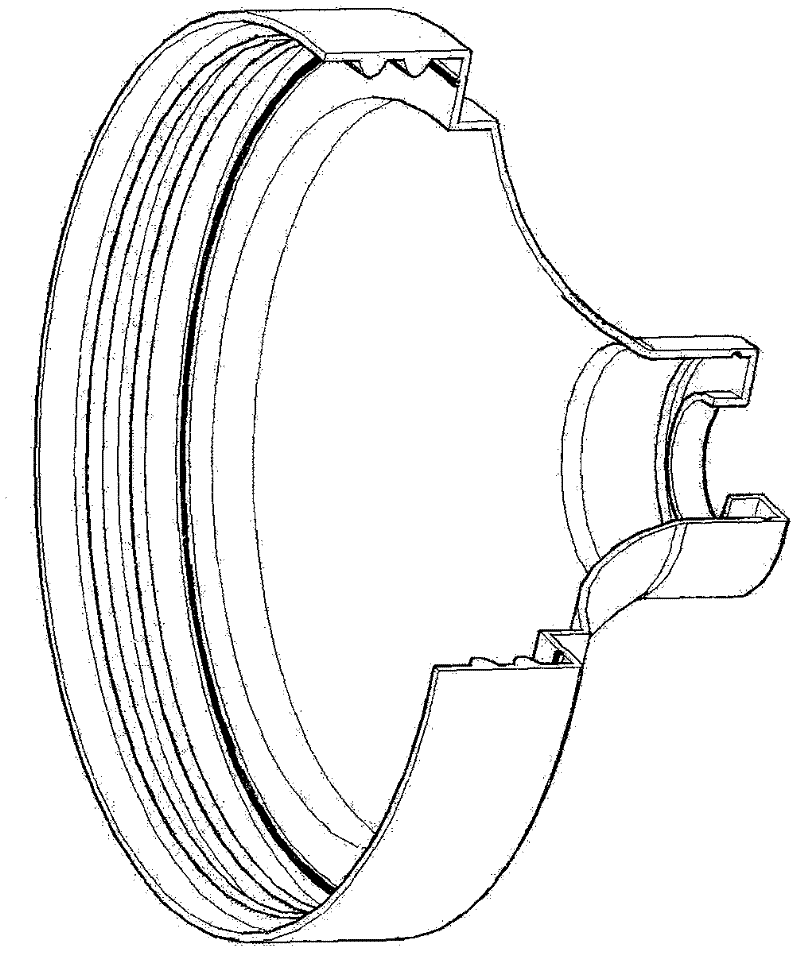

[0023] Such as Figure 4 , Figure 5 As shown, the diaphragm valve 3 is made of elastic rubber, and the vault is provided with a cross-shaped incision. When the bottle body is turned upside down, the gravity generated by the weight of the oil in the bottle is not enough to pull the cross-shaped cut open. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com