Environment-friendly oily fume processor

A technology for processing machine and oil fume, applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc., can solve the problems of increasing the number of cleaning of the collecting grid, external air pollution, inability to purify, etc., to increase environmental protection, reduce The effect of cleaning volume and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

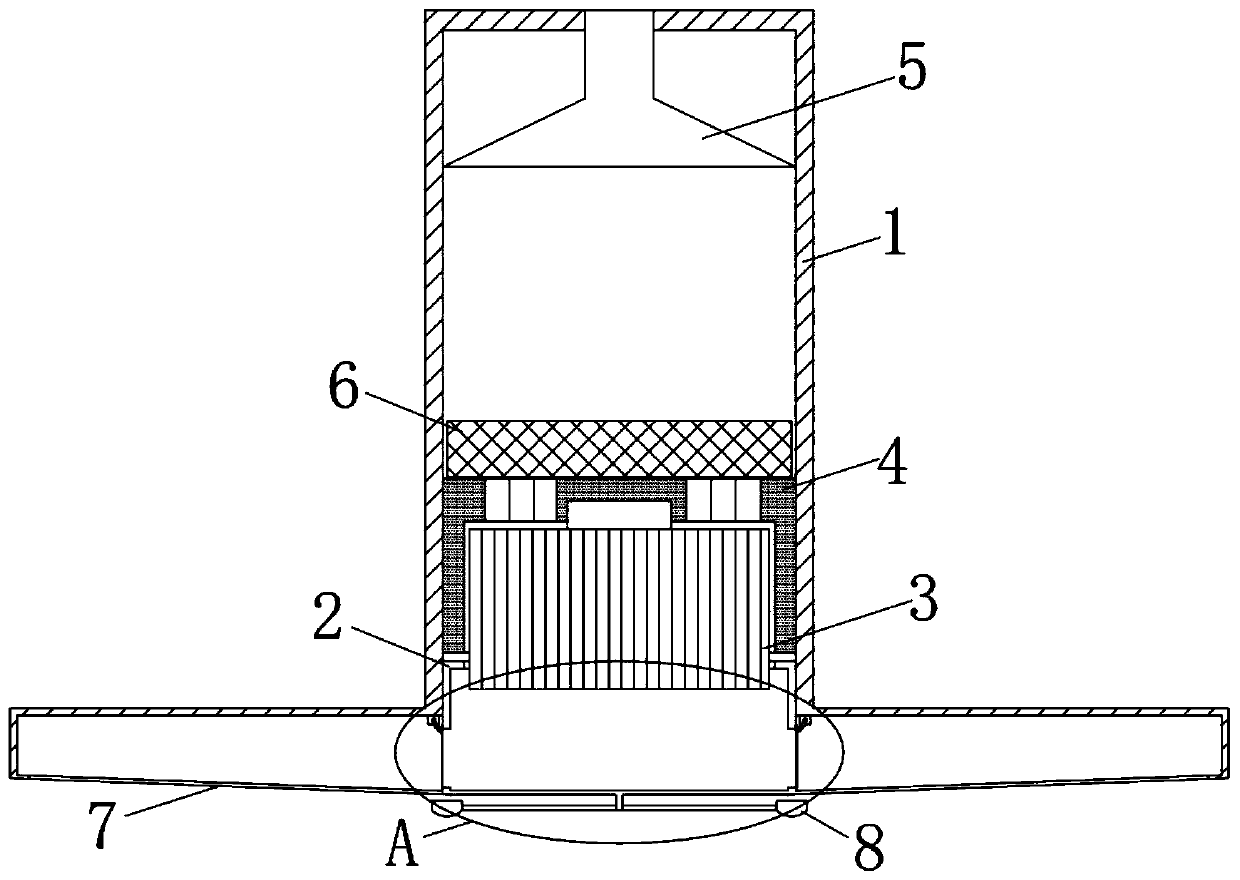

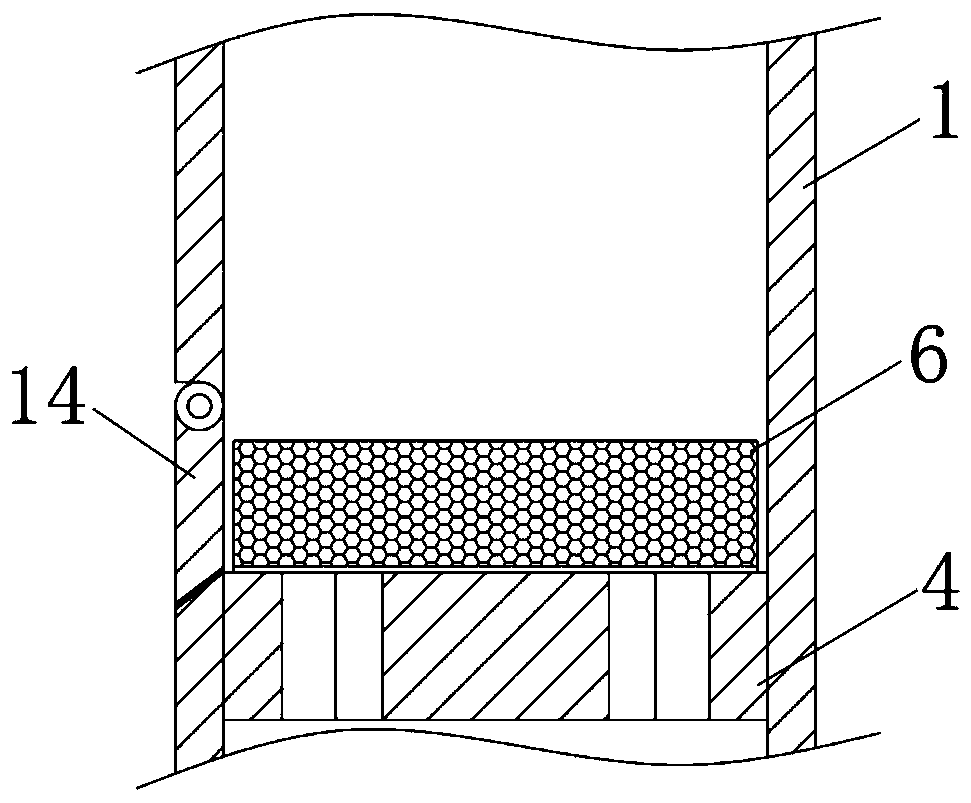

[0025] refer to Figure 1-4 , a kind of environment-friendly lampblack processing machine, comprises machine cover 1, and frame 4 is installed in machine cover 1, and vortex pump 3 is installed on frame 4, and filter core seal door 14 is installed on machine cover 1, and filter core seal door 14 Sealing strips are installed all around to keep the airtightness of the hood 1 and ensure that the oil fume will not leak. The filter element sealing door 14 is located on the upper side of the frame 4, and the catalytic adsorption filter element 6 is installed in the filter element sealing door 14, and the catalytic adsorption filter element 6 is installed on the side of the frame 4 away from the vortex pump 3, and the catalytic adsorption filter element 6 and the filter element sealing door 14 are located on the upper side of the frame 4 at the closest position to the vortex pump 3, so that users can easily open the filter element sealing door 14 for replacement Catalytic adsorption ...

Embodiment 2

[0031] refer to Figure 5 , an environmentally friendly oil fume processor provided in this embodiment is basically the same as Embodiment 1, the difference is that:

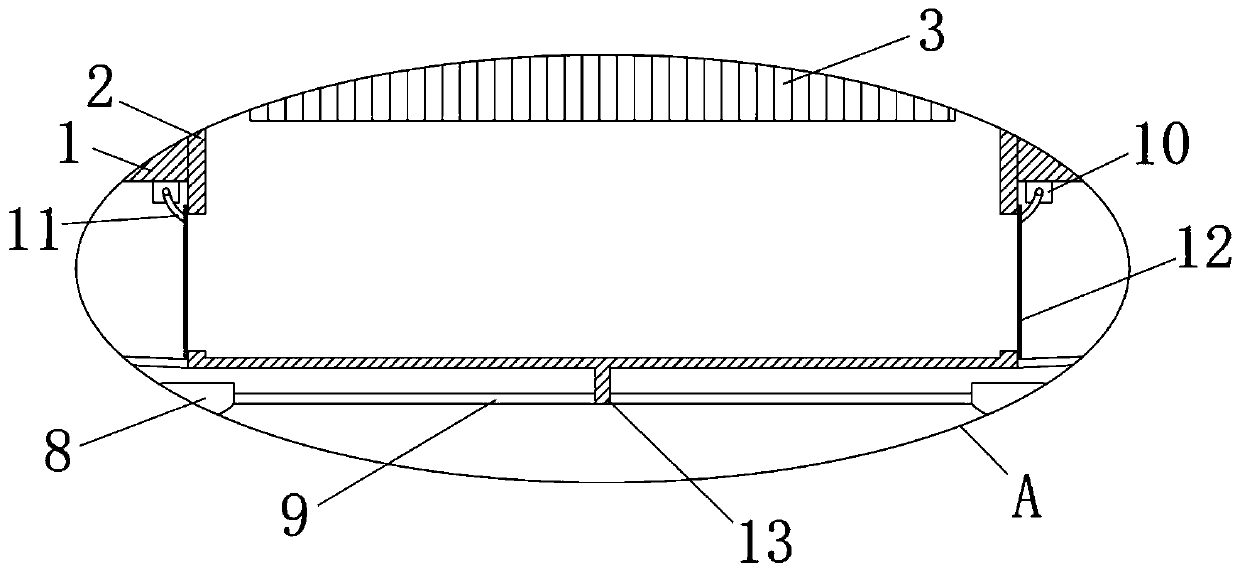

[0032] The hood 1 is located below the vortex pump 3 and a flow divider 2 is installed, and the flow divider 2 is covered on the vortex pump 3. The flow divider 2 includes two symmetrically arranged air outlets, each of which is away from the side of the vortex pump 3 Each cover is provided with a sealing plate 12, each sealing plate 12 is equipped with a connecting piece 11, and each connecting piece 11 is equipped with a motor 10, and the connecting piece 11 is connected with the output shaft of the motor 10, through the rotation of the motor 10 , to drive the sealing plate 12 to rotate, and rotate from the air outlet to the inner side of the hood 1. The two motors 10 can independently control the rotation of the sealing plate 12 through the buttons. Press both control buttons, and the two ventilation holes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com