Modified polyester/cotton blended fabric and dyeing method thereof

A technology for modifying polyester and blended fabrics, which is applied in dyeing, liquid/gas/steam textile material processing, textiles and papermaking, etc. It can solve the problems of high modulus of polyester fibers, lower product grades, easy pilling, etc. problems, to achieve the effect of high tensile strength, high tensile elongation at break, and high dye uptake

Active Publication Date: 2011-01-26

CHINESE TEXTILE ACAD

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although polyester and cotton blended fabrics are very mature products with a huge variety and output, due to the high modulus and high strength of polyester fibers, such fabrics generally have the disadvantage of easy pilling, and the polyester content is slightly The chemical fiber feeling of high-grade fabrics is relatively strong, which obviously reduces the product grade

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

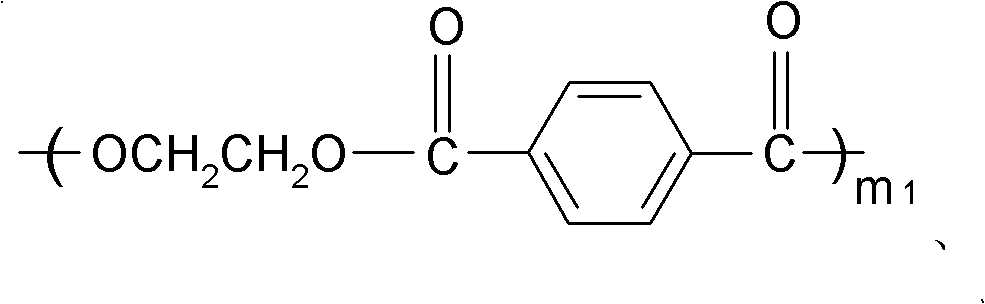

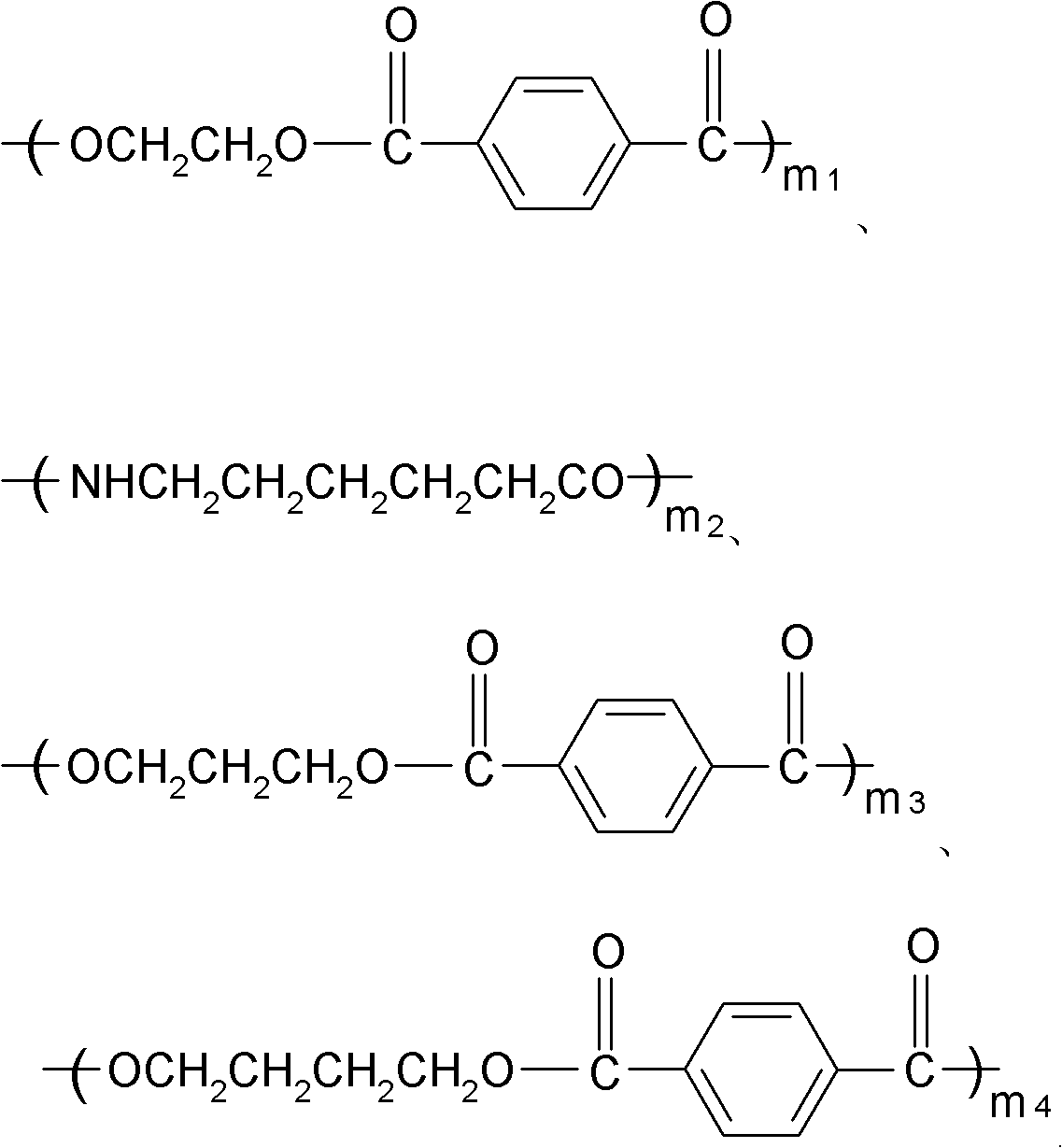

Login to View More Abstract

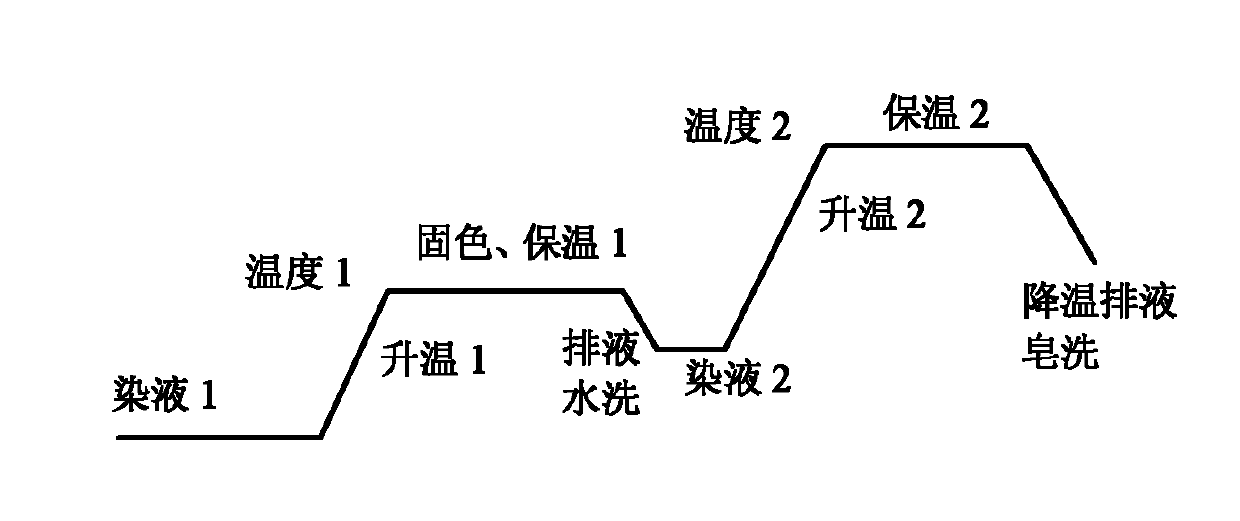

The invention provides a modified polyester / cotton blended fabric and a dyeing method thereof. The fabric is blended by modified polyester and cotton, wherein the modified polyester is copolymerized by polyester and nylon 6, and has the structural unit as the specification, wherein m1 is more than 1 and less than 160, m2 is more than 1 and less than 70, m3 is more than or equal to 0 and less than 20, and m4 is more than or equal to 0 and less than 20; the blended fabric has the performance of normal-temperature normal-pressure dyeing, and soft handfeel and good antipilling performance with the antipilling grade over 3 grades. The invention also relates to a method for dyeing the blended fabric. An acid dye or an acid dye and a disperse dye are used for one-bath dyeing so as to simplify the dyeing process and contribute to energy conservation and emission reduction; and the dyeing temperature is below 100 DEG C to remarkably reduce energy consumption.

Description

technical field The invention relates to a blended fabric and a dyeing method thereof, in particular to a modified polyester and cotton blended fabric and a dyeing method thereof. The modified polyester and cotton blended fabric is dyed at normal temperature with reactive dyes and disperse dyes. Background technique The dyeing properties of ordinary polyester fibers and cotton are very different: polyester fibers are generally dyed with disperse dyes at high temperature and high pressure, and the dyeing temperature is above 120°C, and high temperature and high pressure dyeing machines must be used; cotton is generally dyed with reactive dyes, direct dyes, and vat dyes etc. for dyeing, the dyeing temperature is below 100°C, and a normal temperature and pressure dyeing machine is used. The difference in dyeing properties has brought great trouble to the dyeing of polyester and cotton blended fabrics. Cotton is prone to dye hydrolysis when dyed under high temperature conditions...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06P3/872D06B3/10D02G3/04

Inventor 廉志军潘菊芳和超伟井连英白玲李鑫

Owner CHINESE TEXTILE ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com