Energy-saving gas stove with thermal radiation net structure

A heat radiation and gas furnace technology, applied in the direction of heating fuel, gaseous heating fuel, household cooking utensils, etc., to achieve the effect of reducing the discharge rate, improving the utilization rate of heat energy, and smoothing the fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

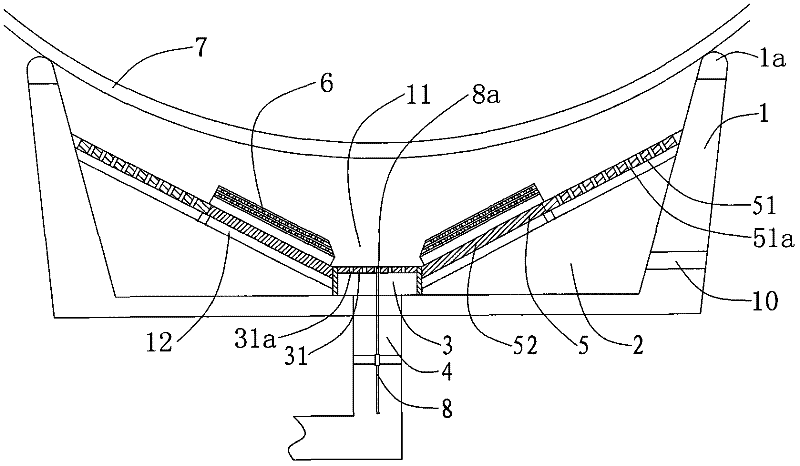

[0035] Such as figure 1 The shown energy-saving gas stove with a heat radiation net structure includes a furnace body 1 , a blast furnace head 3 located in the furnace body cavity 2 , and a mixed gas pipe 4 communicating with the blast furnace head 3 . The upper end surface of the furnace body 1 is formed with a sealing support portion 1a which is sealed and fitted with the bottom of the pot body 7 . A thermal insulation layer 5 is arranged between the inner wall of the furnace body 1 and the blast burner head 3, and the thermal insulation layer 5 divides the inner chamber of the furnace body 2 into upper and lower parts. The surface of the outer ring of the heat insulation layer 5 is formed with a through hole 51a that communicates with the upper and lower parts of the furnace body cavity 2, and the top of the through hole 51a is formed with a horn-shaped opening. At least one heat radiation mesh layer 6 is fixedly arranged above the heat insulation layer 5 . The lower part...

Embodiment 2

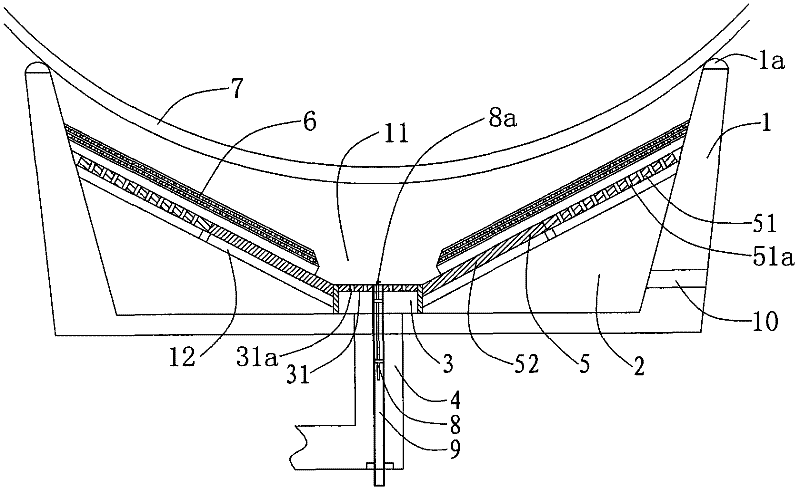

[0045] In this embodiment, the energy-saving gas stove with heat radiation net structure is as follows: figure 2 As shown, it includes a furnace body 1 , a blast furnace head 3 located in the furnace inner chamber 2 , and a mixed gas pipe 4 communicating with the blast furnace head 3 . The upper end surface of the furnace body 1 is formed with a sealing support portion 1a which is sealed and fitted with the bottom of the pot body 7 . A thermal insulation layer 5 is arranged between the inner wall of the furnace body 1 and the blast burner head 3, and the thermal insulation layer 5 divides the inner chamber of the furnace body 2 into upper and lower parts. A through hole 51a connecting the upper and lower parts of the furnace body cavity 2 is formed on the surface of the outer ring of the heat insulation layer 5, and at least one layer of heat radiation mesh layer 6 is fixedly arranged above the through hole 51a. The lower part of the inner cavity 2 of the furnace is provided...

Embodiment 3

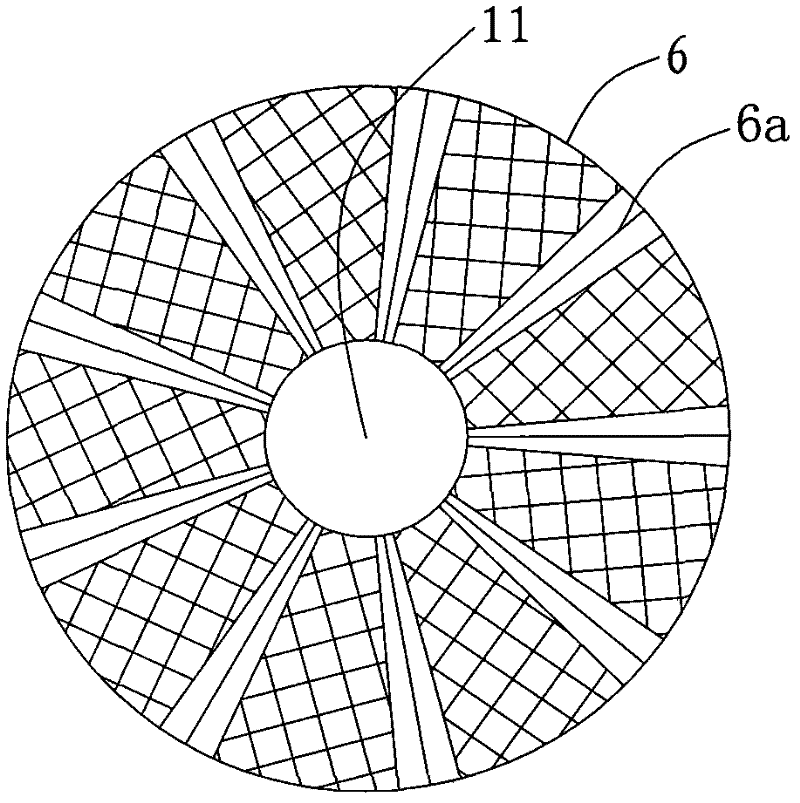

[0051] This embodiment is on the body of furnace structure of embodiment 1 or embodiment 2, adopts Figure 5 Heat radiation mesh layer 6 is shown. The heat radiation mesh layer 6 can be made integrally, or can be composed of multiple pieces of heat radiation mesh units 61 spliced together.

[0052] The heat radiation mesh layer 6 of the present embodiment is concentric wave ring, as Figure 5a In the sectional view shown, the heat radiation net unit 61 is wavy from the center to the outside, and the lower surface forms a supporting edge 61a, which is placed on the heat insulation layer 5, at least covering the outer ring of the heat insulation layer 5, and can also cover Whole thermal insulation layer 5. After the gas burns, since the heat radiation mesh layer 6 is located between the heat insulation layer 5 and the pot body 7, the heat flow will pass through the screen mesh of the heat radiation mesh layer 6, thereby fully heating the heat radiation mesh layer 6 and turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com