High pressure generator with dilute solution preheater for direct combustion lithium bromide air conditioner

A high-pressure generator and dilute solution technology, applied in generator/analyzer, air conditioning system, refrigeration and liquefaction, etc., can solve the problem of low utilization rate of heat source, achieve the effect of improving efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

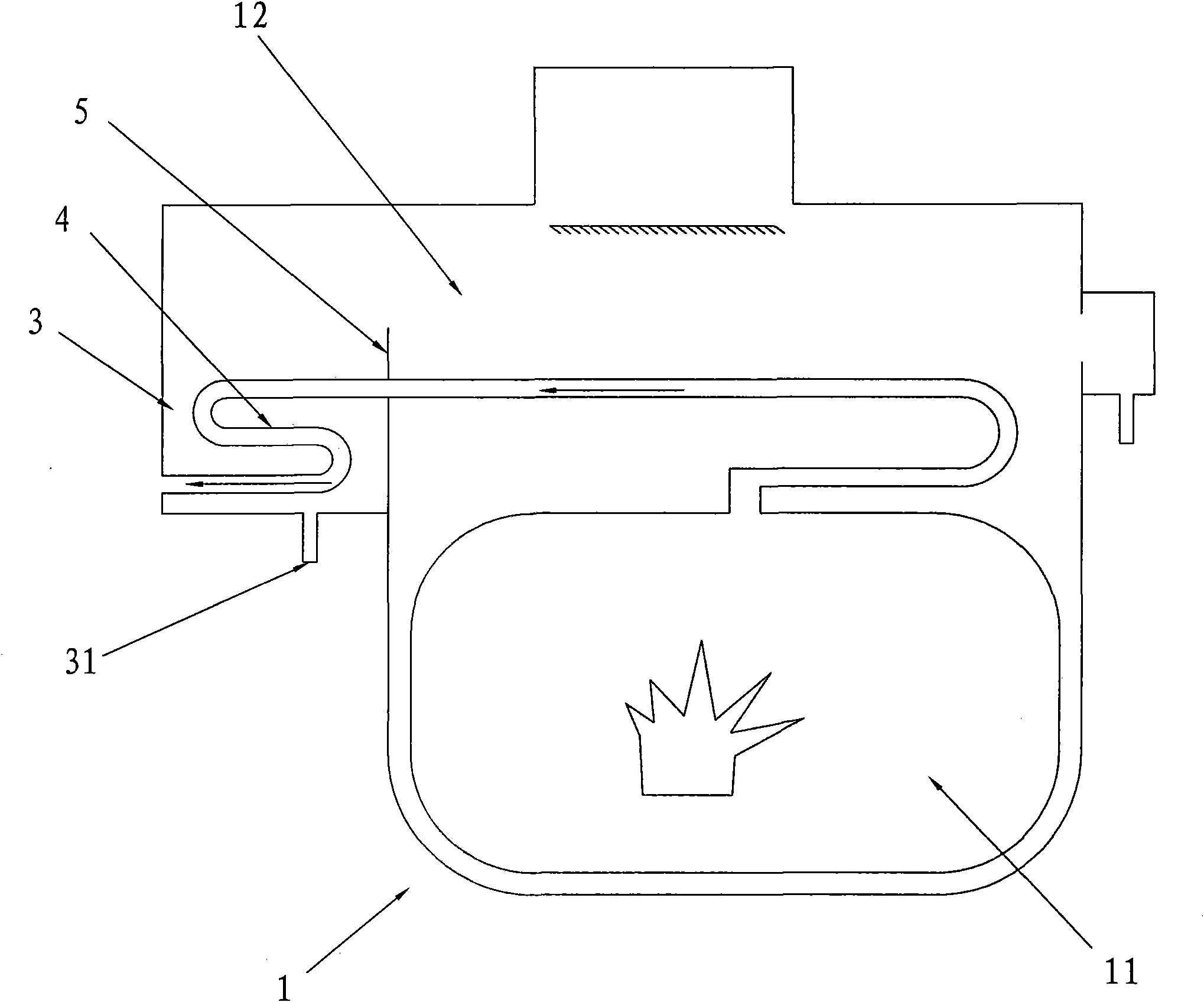

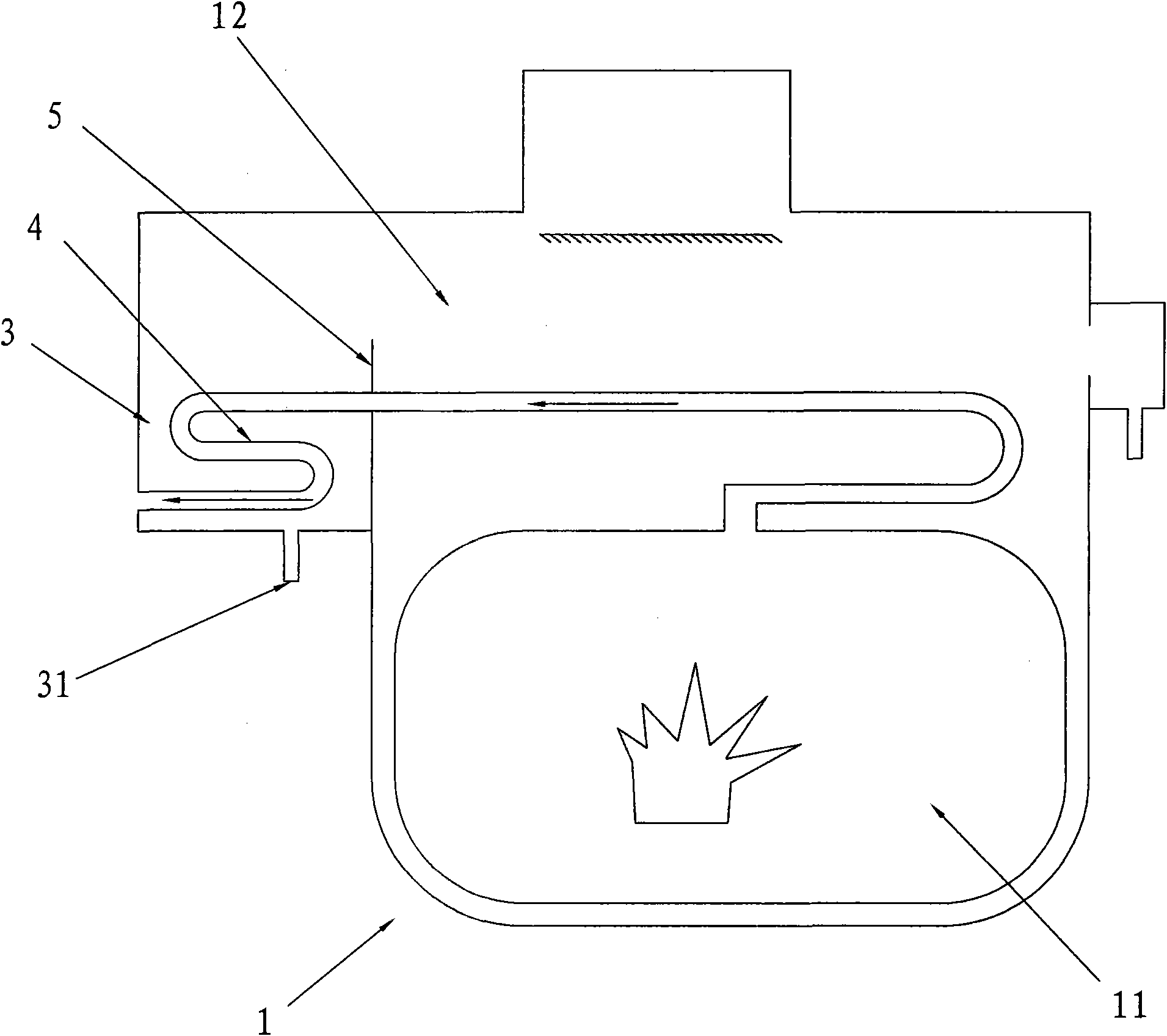

[0010] Such as figure 1 As shown, a direct-fired lithium bromide air-conditioning high-pressure generator with a dilute solution preheater includes a body 1, and the body 1 has a combustion chamber 11 and an evaporation chamber 12; a smoke pipe 2 communicates with the outside world on the combustion chamber 11. It also includes a dilute solution preheating chamber 3 and a heater 4;

[0011] The dilute solution preheating chamber 3 communicates with the evaporation chamber 12, the dilute solution preheating chamber 3 has a dilute solution inlet 31, and a partition 5 is arranged at the junction of the dilute solution preheating chamber 3 and the evaporation chamber 23;

[0012] The heater 4 is arranged in the dilute solution preheating chamber 3 , the smoke pipe 2 passes through the evaporation chamber 12 and is connected to the smoke inlet of the heater 3 , and the smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com