Suction type optical disc drive

A kind of optical disc drive and suction-type technology, which is applied in the direction of recording information storage, instruments, etc., can solve the problems of shortening the life of electronic parts, unable to test points and maintenance positions, and is not conducive to the thinning of the suction-type optical disc drive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to achieve the above object, the present invention adopts the technical means and its effects, hereby give preferred embodiments, and illustrate as follows in conjunction with the accompanying drawings.

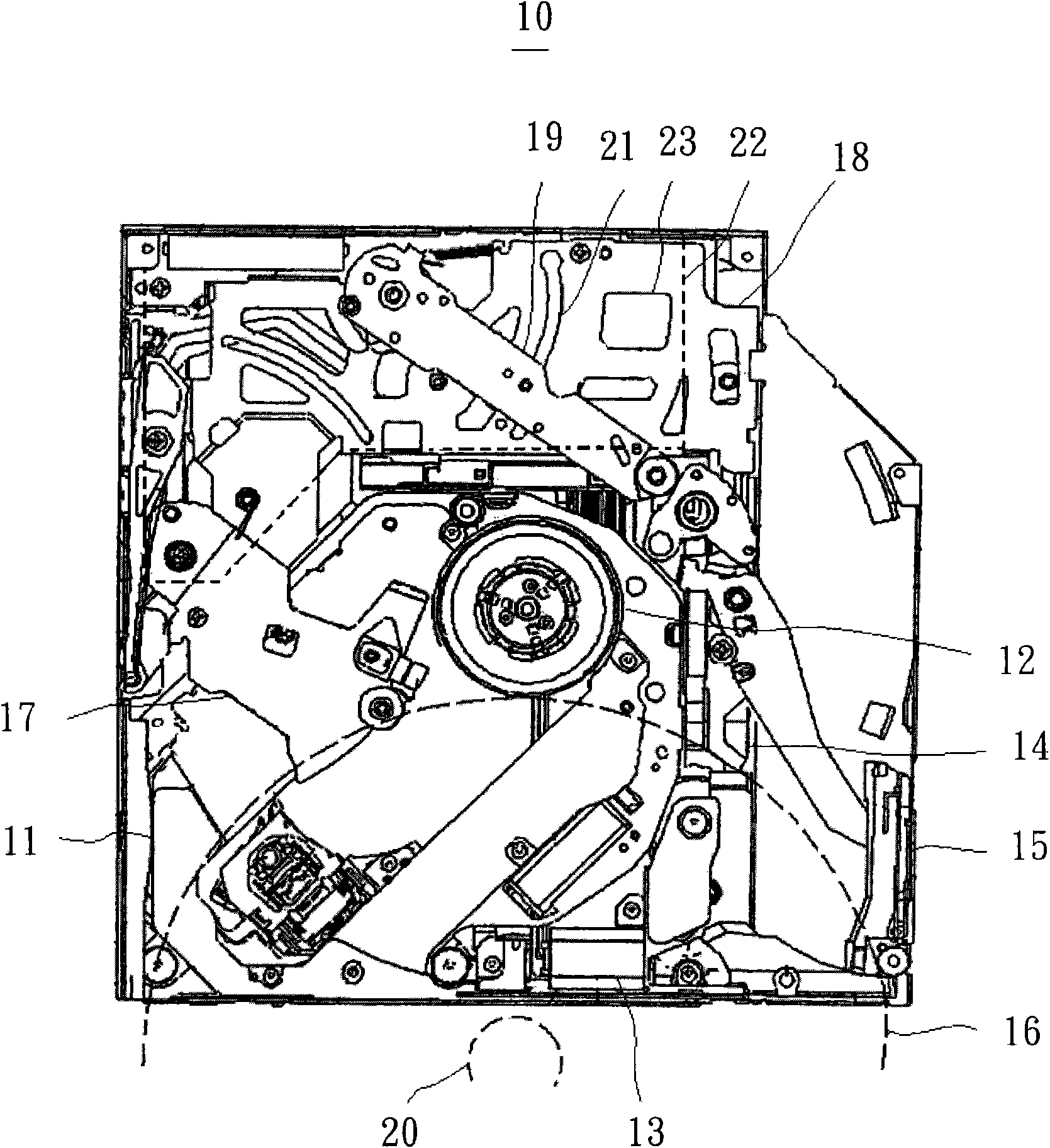

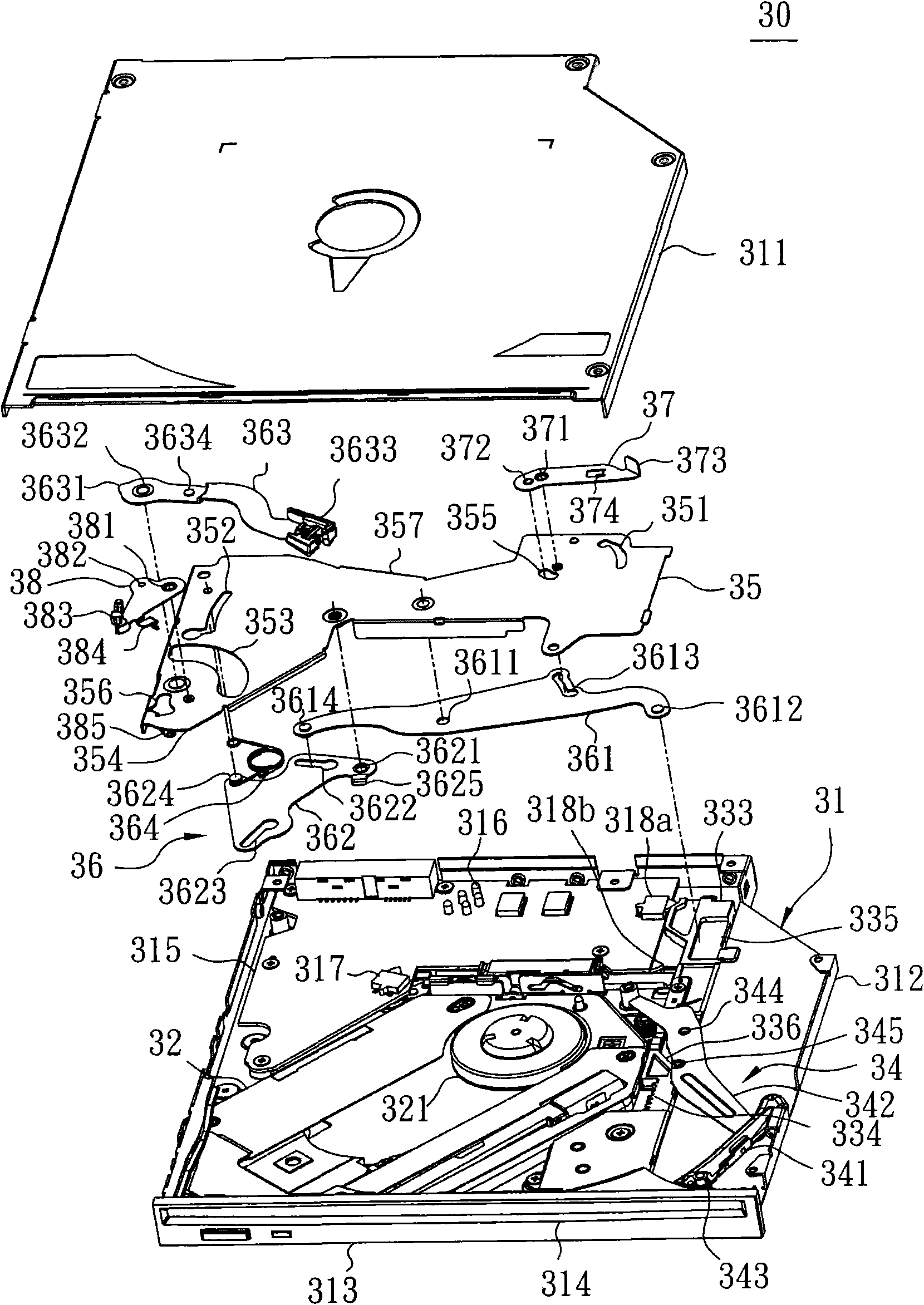

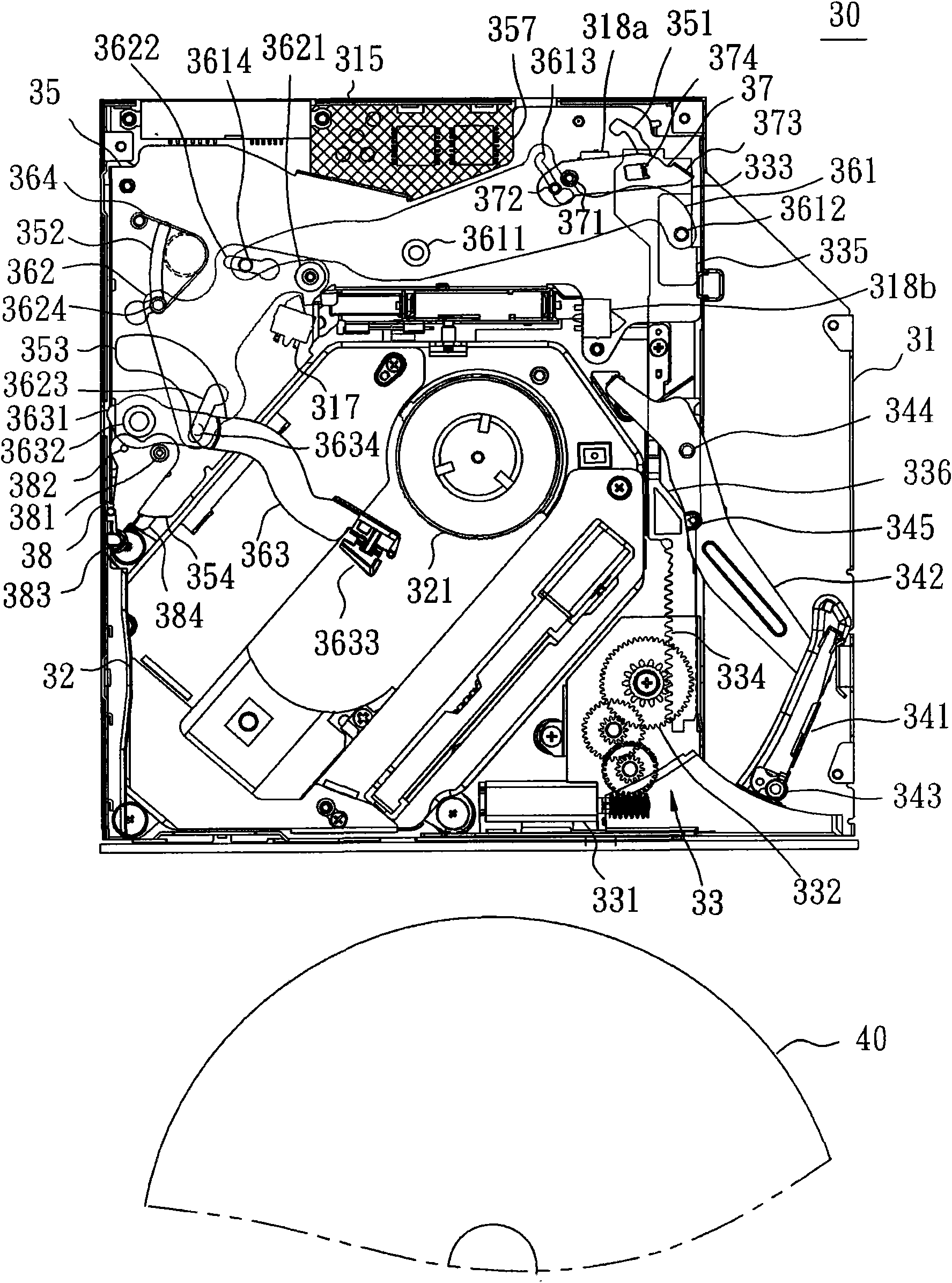

[0082] Please also refer to figure 2 and image 3 , figure 2 It is an exploded view of the parts of the slot-in optical disk drive 30 of the present invention, image 3 It is a top view of the combination of the slot-in disc drive 30 of the present invention. The slot-in disc drive 30 includes a housing 31 , a core 32 , a power unit 33 , a film advance unit 34 , a base plate 35 , a film eject unit 36 , a right positioning rod 37 and a left positioning rod 38 . Wherein, the housing 31 includes an upper shell 311 and a lower shell 312 , has a hollow interior, a front panel 313 is provided, and an inlet and outlet 314 is provided on it for the optical disc 40 to enter and exit. A main board 315 is provided at the bottom of the rear side of the casing 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com