Device for testing the coating of a vane base

A detection device and coating technology, which is applied in the field of coating devices, can solve the problems of unacceptable coating quality differences, insufficient accurate conclusions on durability and mechanical properties, etc., and achieve good representative results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

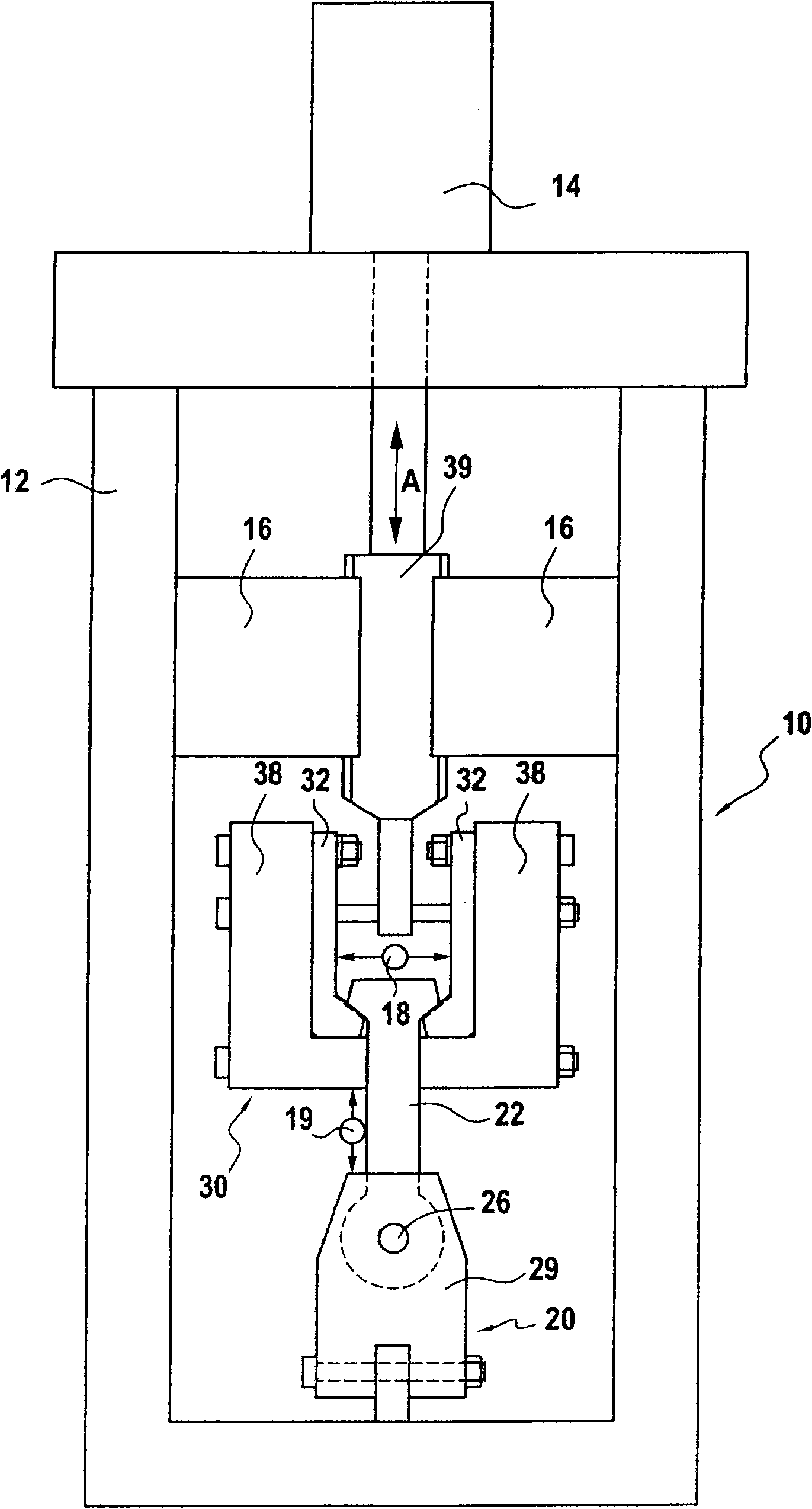

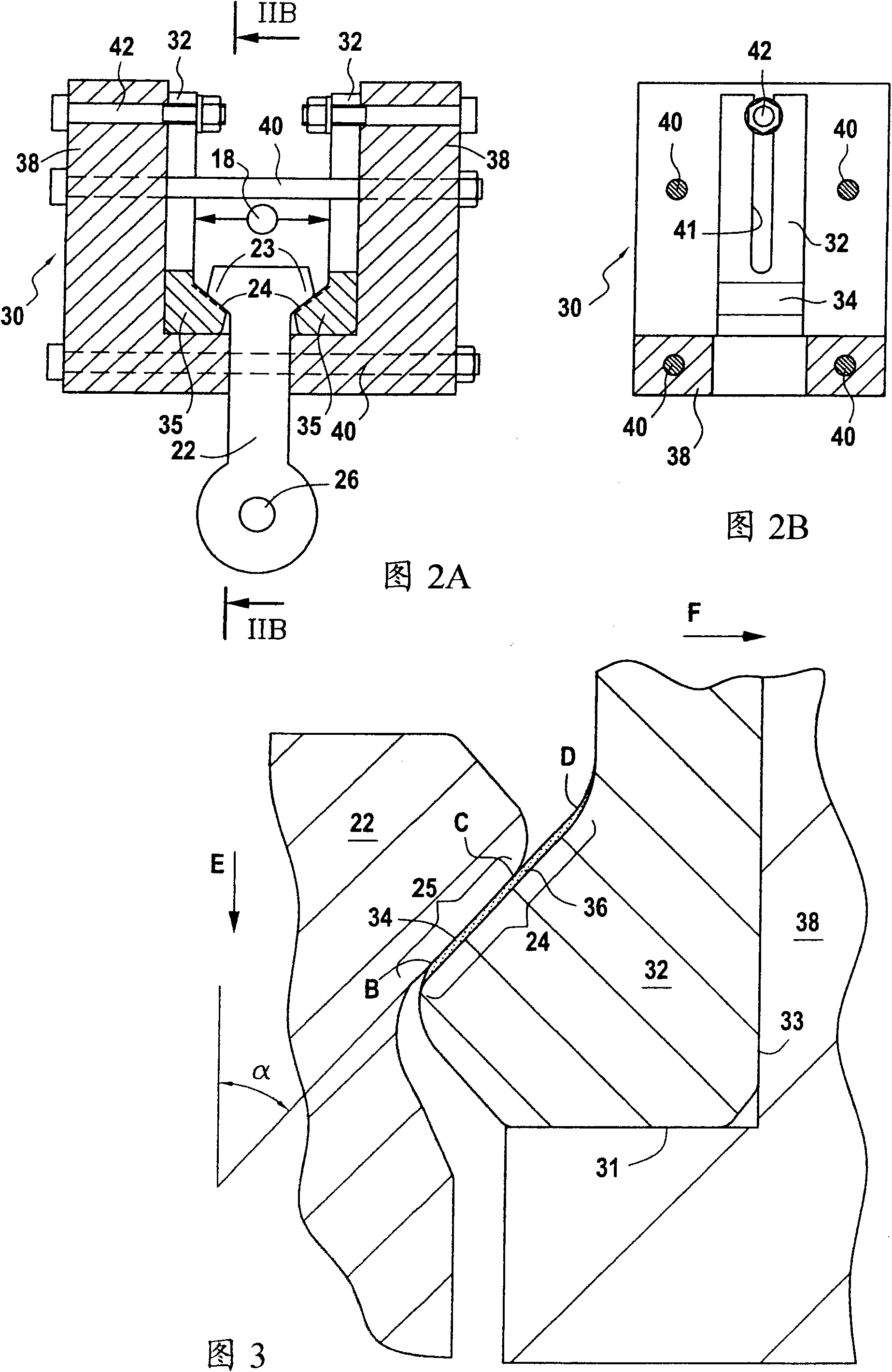

[0032] see figure 1 , a detection device 10 according to the invention for a coating that can be applied to a blade root is now described. This device 10 comprises a machine comprising first of all a frame 12 constituted in its entirety by a mechanically welded frame. This framework 12 supports two retention systems 20 and 30 .

[0033] A first holding system 20 located in the lower part of the machine comprises fixed struts 29 holding the counter detection 22 in position. The counter-test 22 comprises a hole through which a mandrel 26 of the first holding system passes, with which the counter-test 22 is held regardless of the tensile stress it is subjected to.

[0034] A second holding system 30 is used to hold the two detection halves 32 in position. This second holding system 30 comprises a movable beam 39 arranged to be translated alternately along the double arrow A in the vertical direction by the linear actuator 14 or any other equivalent actuation mechanism. This b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com