Mechanical press with twin-stage air cushion device

A mechanical press and air cushion technology, applied in the field of mechanical presses, can solve the problems of air cushion sealing ring failure, failure, and the sealing ring cannot be reliably lubricated, etc., and achieves the effect of good maintenance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

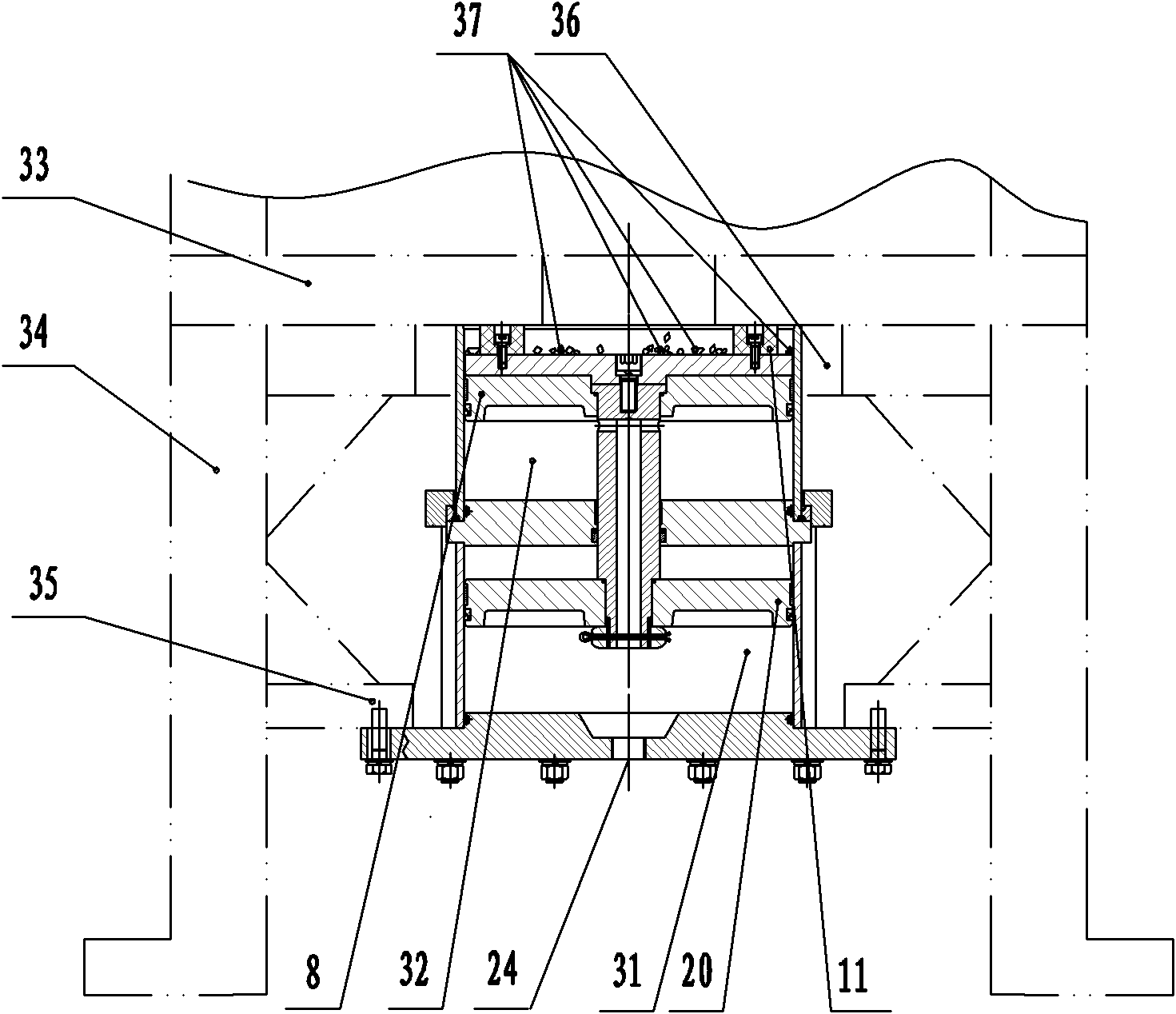

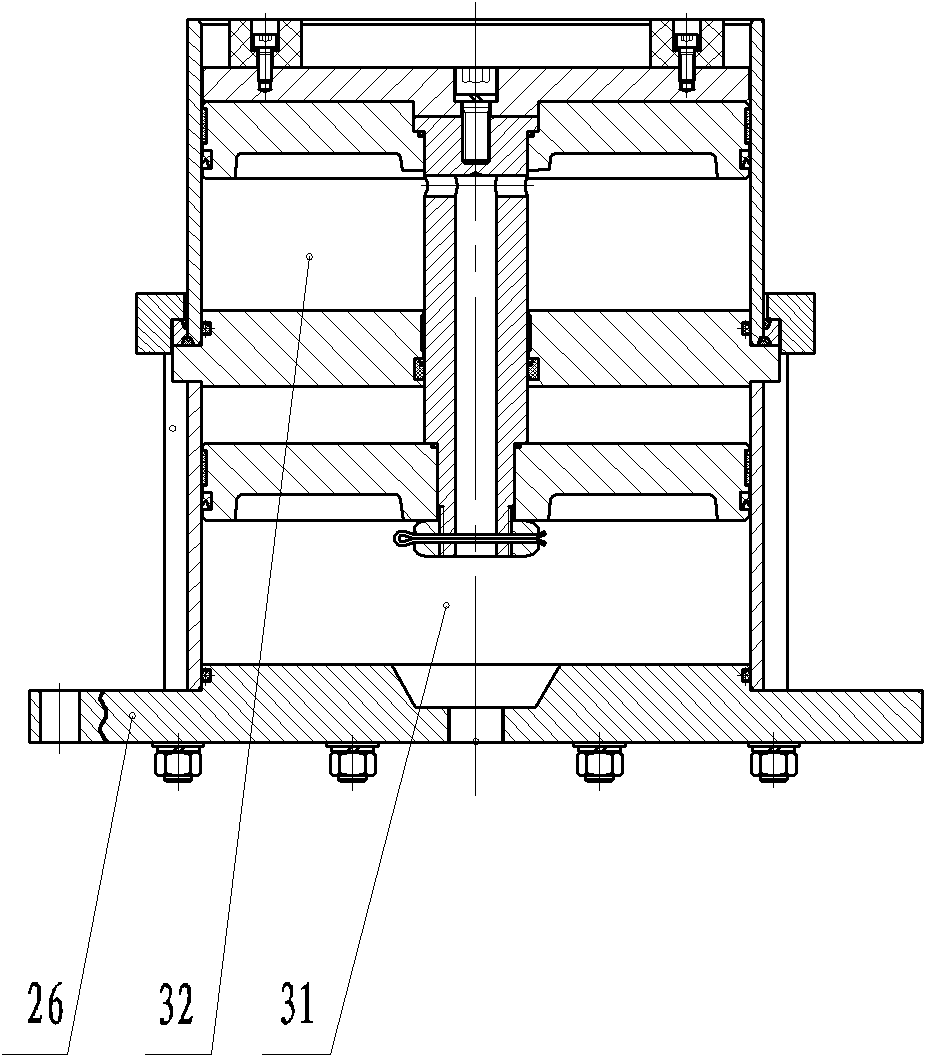

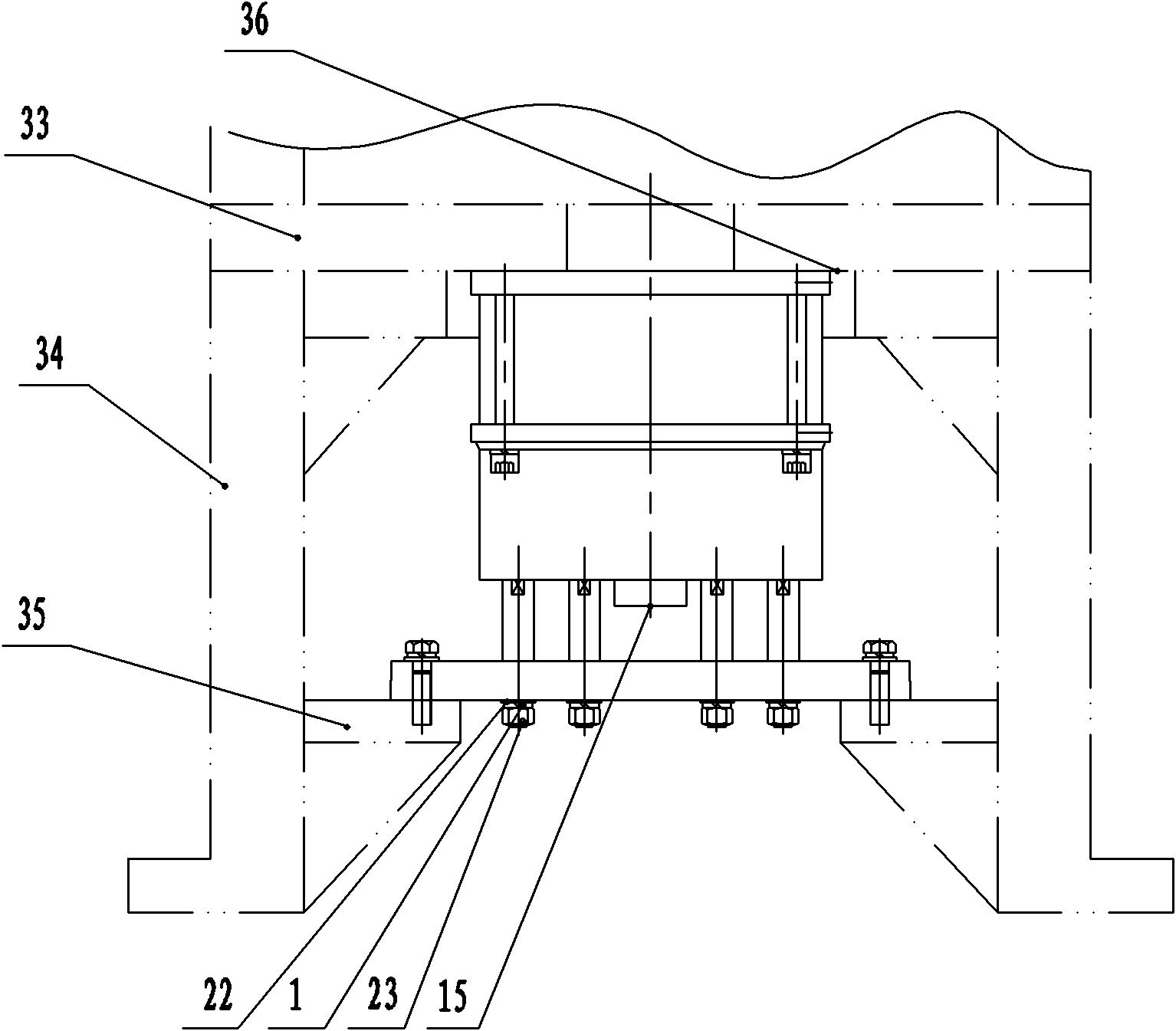

[0020] As shown in the figure: the mechanical press with a two-stage air cushion device includes a bed 34, an upper end cover 3, a middle end cover 29, an upper cylinder body 5, a lower cylinder body 28, an upper piston 8, a lower piston 20 and a piston rod 15. The upper cylinder body 5, the lower cylinder body 28 are fixedly connected with the middle end cover 29, the middle through hole of the middle end cover 29 is provided with a Y-shaped sealing ring 13, and the upper end cover 3 is fixedly installed on the top of the upper cylinder body 5, An O-shaped sealing ring 4 is arranged between the upper cylinder body 5 and the upper end cover 3, and the upper piston 8 is slidably and sealingly connected in the upper cylinder body 5, and the lower piston 20 is slidably and sealingly connected in the lower cylinder body 28; the upper end of the piston rod 15 is conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap