Method for sticking studs, rhinestones and hot films

A kind of hot bead hot drill hot piece, hot bead hot drill technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A method for pasting hot beads and hot drill hot sheets, such as Figure 4 shown, including steps:

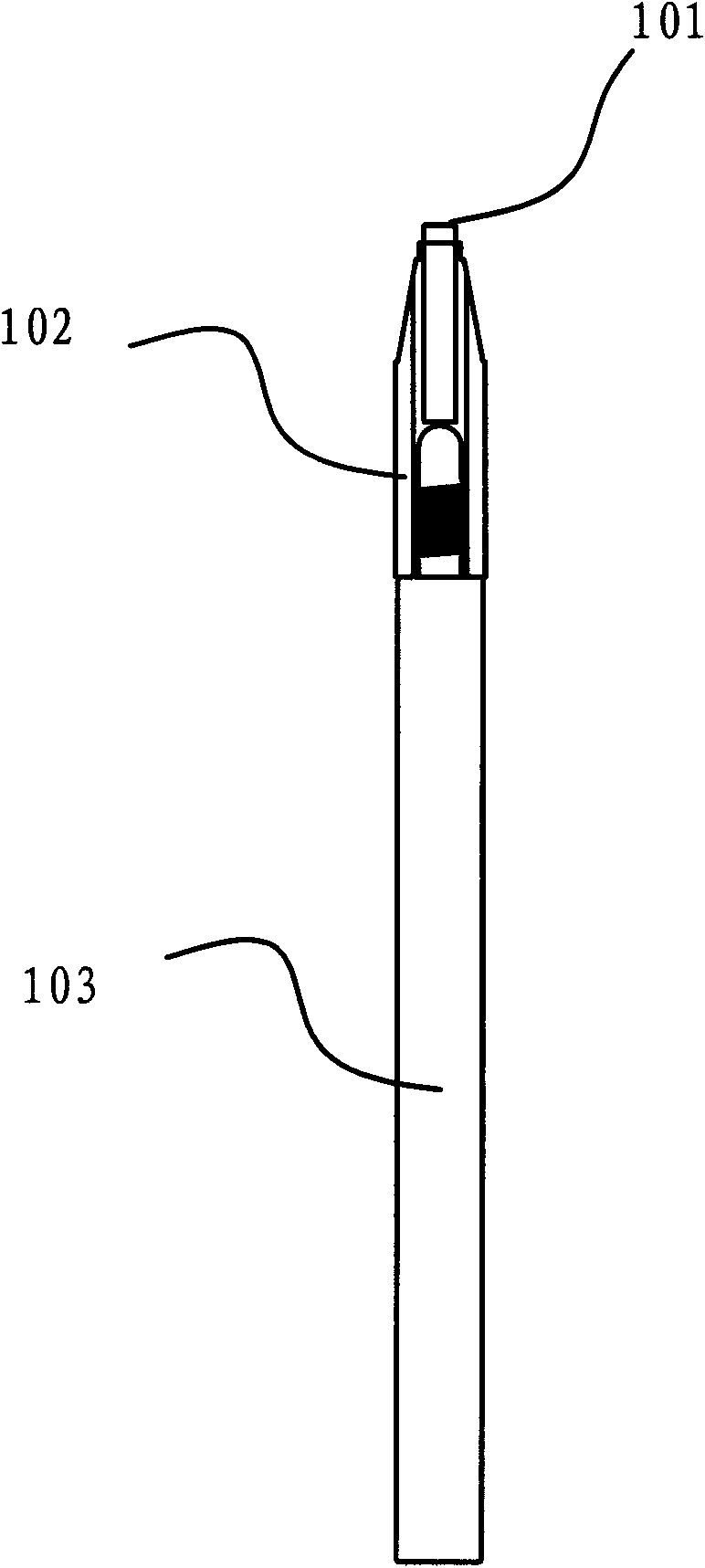

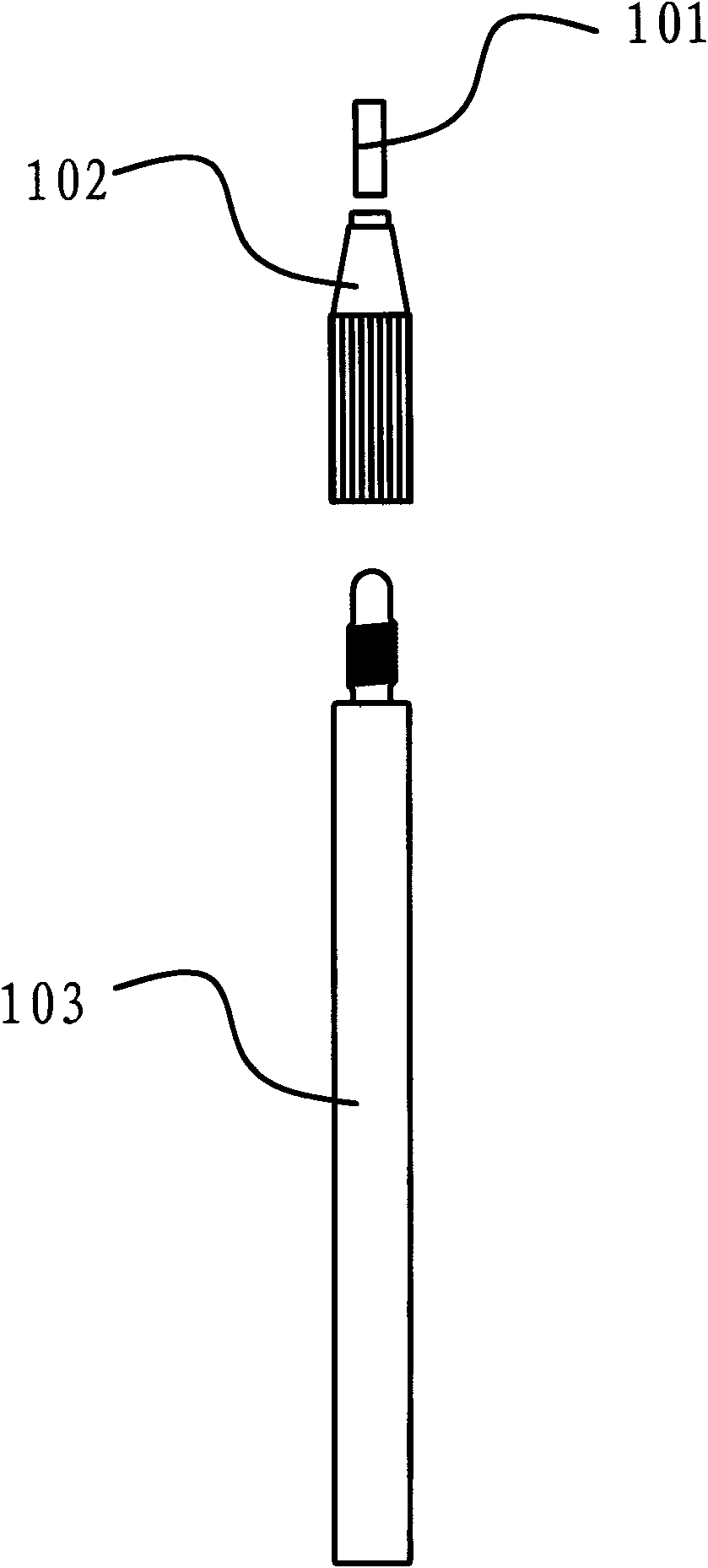

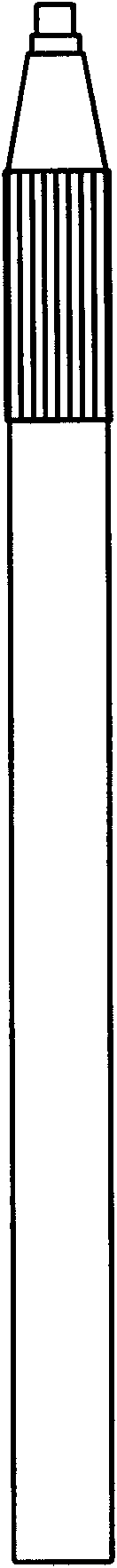

[0025] 101. Stick hot beads, hot drills or hot pieces with a sticky pen;

[0026] In this embodiment, preferably, the sticky pen is a sticky pen made of soft rubber materials such as PVC, PU, silica gel, and enamel.

[0027] 102. Use the paste pen to place the hot beads, hot sheets or hot drills on the transparent board;

[0028] Preferably, in this embodiment, the transparent board also has a sheet made of soft rubber materials such as PVC, PU, silica gel, and enamel, for placing the above-mentioned hot beads, hot drills, hot sheets, etc. Patterns can be pre-arranged under the transparent board, and the sticky sticky pen places the hot beads, hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com