Shower water heat exchanging floor drainage

A technology for shower water and floor drain, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of high cost, high installation difficulty, and difficulty in popularization, etc., and achieves the effects of low cost, simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

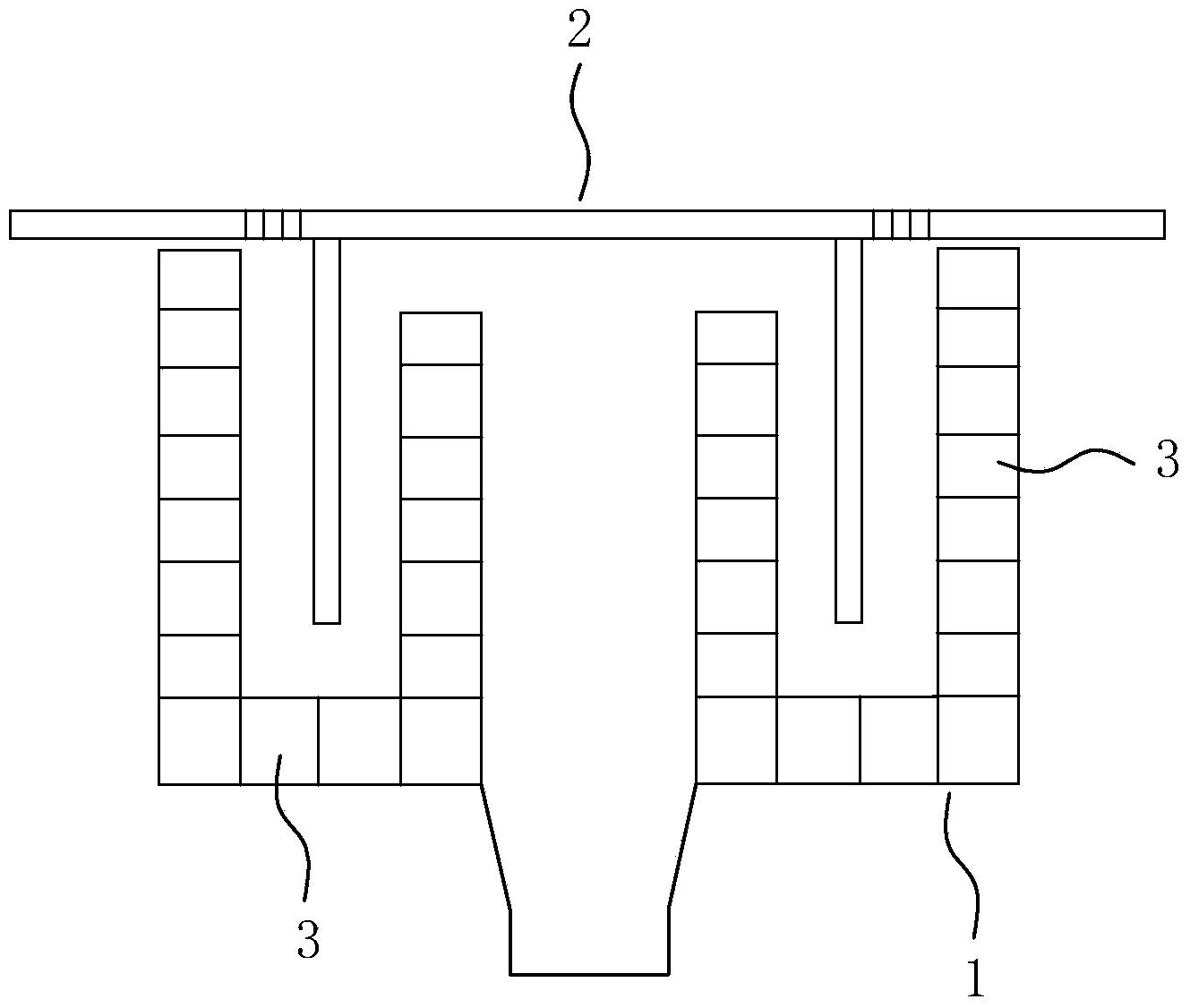

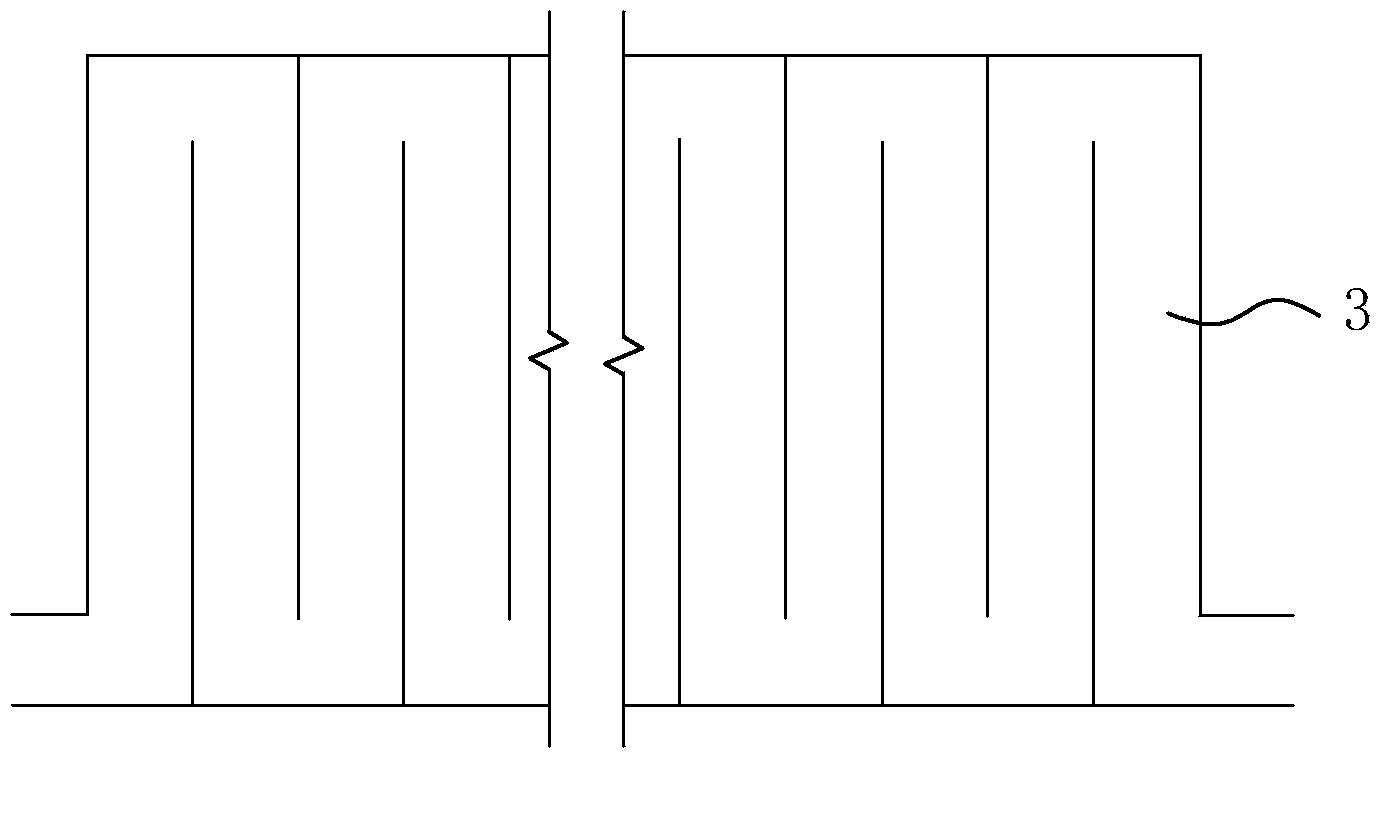

[0010] Such as Figure 1-2 As shown, a shower water heat exchange floor drain includes a trap main body 1 and a bowl sieve plate 2 . In the present invention, a curved pipe 3 is arranged in the wall of the curved groove of the main body 1 of the water trap, and both the main body 1 and the pipe 3 of the water trap are made of heat-conducting materials.

[0011] Specifically, such as figure 1 As shown, the curved groove wall of the main body 1 of the water trap is set to be hollow, and the cavity is divided into several circles of horizontally surrounding pipes 3. Following the distribution of the pipes 3, these pipes 3 are connected in series from end to end in sequence, and respectively reserved A water inlet and a water outlet. or, if figure 2 As shown, the side cavity of the curved groove wall of the main body 1 of the water trap is divided into several vertical pipes 3, and the bottom cavity is divided into surrounding pipes 3, and these pipes 3 are connected in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com