Particle filtering and regenerating device

A particle filtration and particle technology, which is applied to mufflers, exhaust devices, engine components, etc., can solve the problems of high manufacturing cost, large vehicle space, complex structure, etc., and achieve low modification costs, overall cost reduction, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

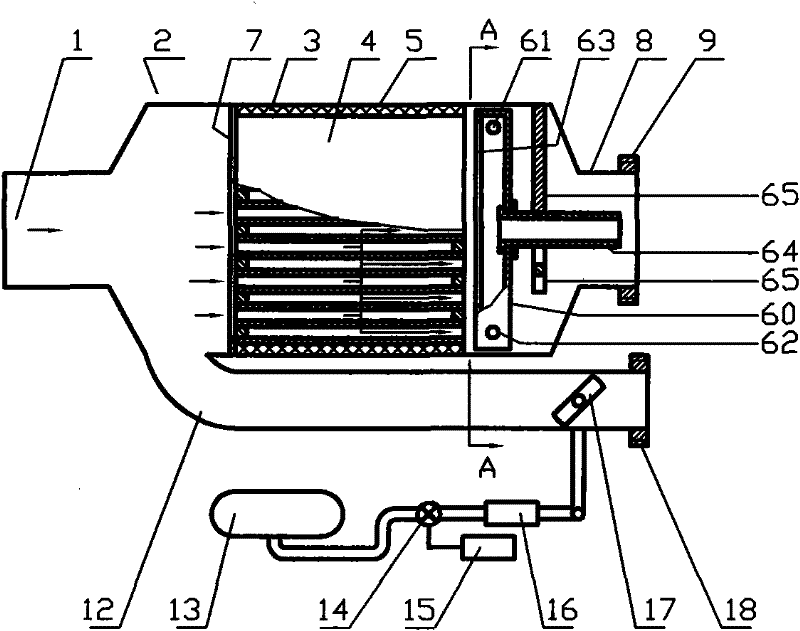

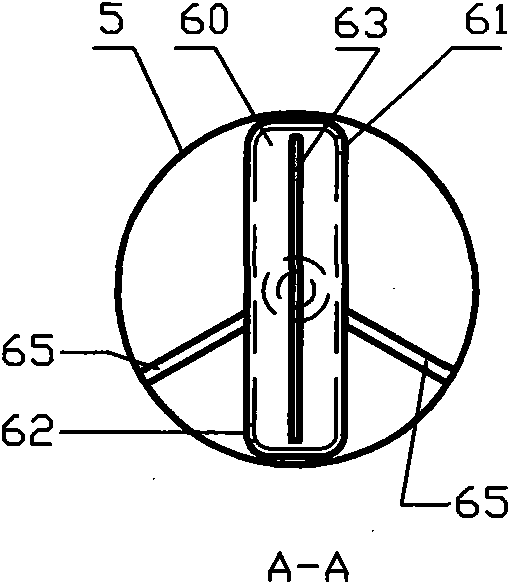

[0014] figure 1 , figure 2 It is a schematic structural diagram of an embodiment of the particle filter device 2 of the present invention, figure 1 The arrow in front of the ceramic filter 4 in the middle is the exhaust gas flow direction containing particles, and the arrow in the ceramic filter 4 is the exhaust gas flow direction without particles. Now refer to the accompanying drawings.

[0015] The structure of the particulate filtering device has been described in the summary of the invention. The ceramic filter 4 described in this embodiment is a wall-flow filter ceramic with a diameter of 190 mm and a length of 200 mm.

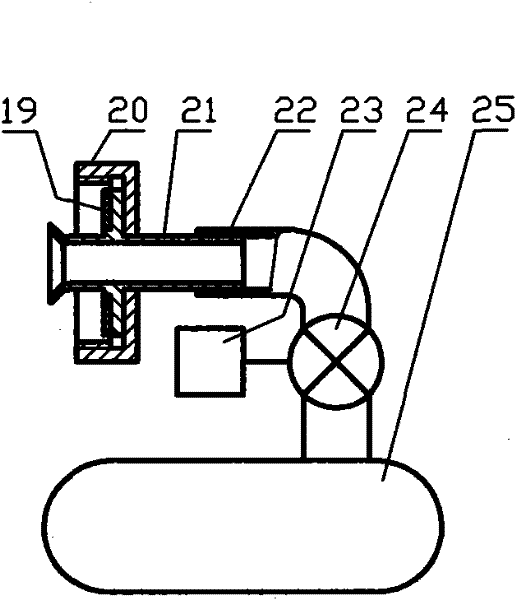

[0016] Described butterfly valve 17 is connected with a pneumatic component 16, and pneumatic component 16 is cylinder, piston, spring structure, and cylinder is fixed, and when sending air to cylinder, piston advances, and butterfly valve is closed, and spring makes piston return when cylinder is empty, and butterfly valve opens, Its gas source come...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com