Fully-enclosed dustproof energy-saving anti-deviation belt conveyer

A belt conveyor, anti-deviation technology, applied in conveyors, conveyor objects, transportation and packaging, etc., to improve stability, improve service life, and prevent deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

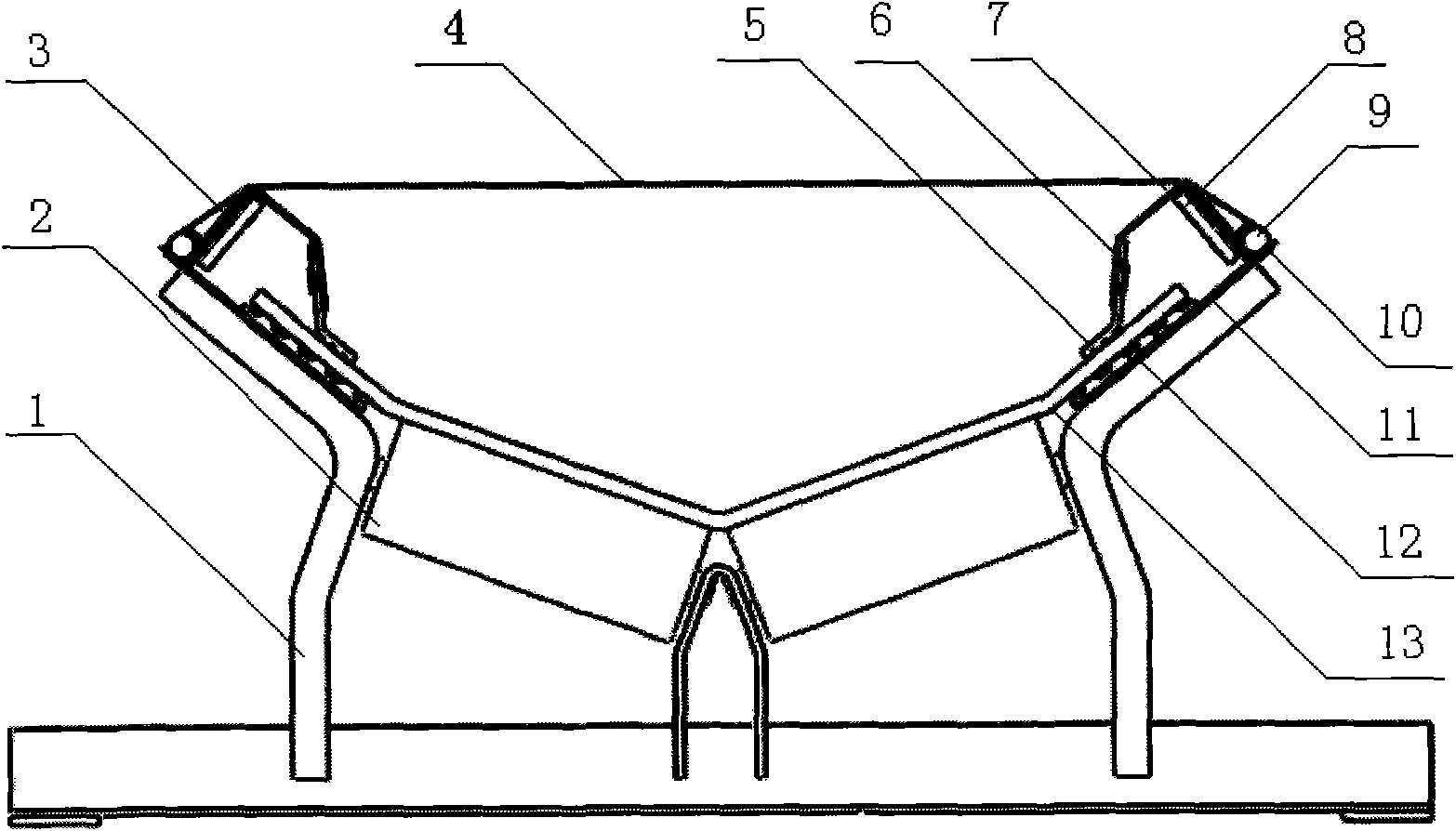

[0032] figure 1 Among them, a multi-sealing component (3) is installed on the upper part of the V-shaped seal energy-saving idler bracket (1), and the flexible shielding material (4) is clamped in the slot (10) by a rubber strip (9), forming three Close the isolation chamber. The main isolation chamber is composed of flexible shielding material (4), upper sealing baffle assembly ( Figure 4), together with the belt (13), the secondary isolation chambers on both sides are jointly composed of multiple sealing components (3) and the belt (13).

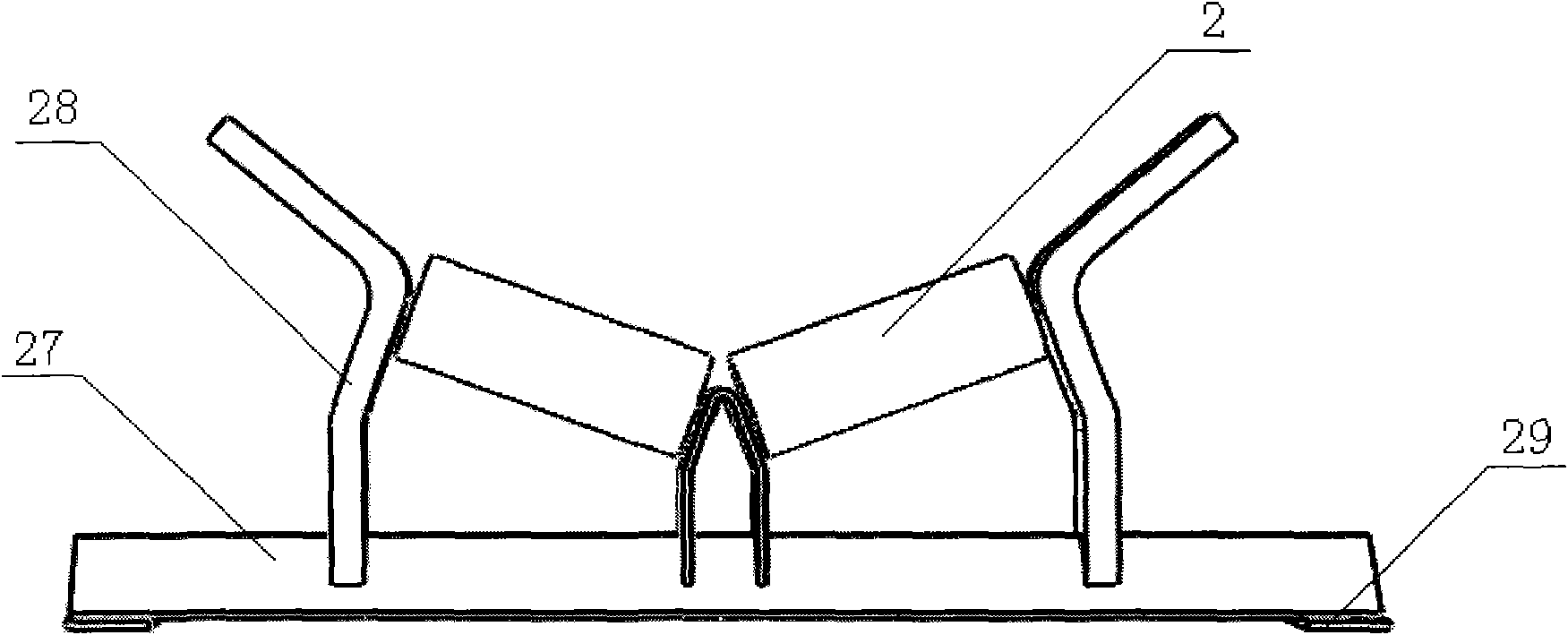

[0033] figure 2 Among them, the V-shaped sealed energy-saving roller support is composed of a low beam of the roller support (27), a supporting leg (28), a connecting plate (29) and two sets of rollers. The supporting legs (28) extend upwards as the connecting bottom plate of the multiple sealing components, and the upwardly extending part forms a certain angle with the supporting rollers, and further draws the belt inwards to improve...

Embodiment 2

[0038] Figure 6 The longitudinal sealing assembly of the middle material receiving section is composed of flexible shielding material (4), fixing strip assembly (15), multiple sealing assembly (3), and material receiving section cover (14). Add a fixed strip assembly (15), connect multiple sealing assemblies (3) with flexible shielding material (4) to form multiple isolation chambers, and finally install a rubber baffle at the end of the material receiving section to prevent dust from overflowing from the end. The sealing assembly of the receiving section can be connected with the sealing assembly of the running section as a part of the sealing of the whole machine, and can also be used alone as a sealing modification scheme for the receiving section.

Embodiment 3

[0040] Figure 7 The sealing assembly of the middle discharge section is equipped with a fixing strip assembly (15) on the edge of the discharge section cover (16), and is connected with the discharge section fixing bracket assembly (17) using a flexible shielding material (4) to form a sealed chamber. It can be connected with the sealing assembly of the running section, as a part of the sealing of the whole machine, and can also be used independently as a sealing modification of the unloading section.

[0041] Figure 8 The fixed bracket assembly (17) of the middle discharge section is composed of a fixed bar assembly (15), an upper bracket (18), a lower bracket (19), an upper baffle (20), and a lower baffle (21). The upper bracket (18) Be connected with the lower support (19) on the conveyor frame with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com